Solid state lighting device

A technology for solid-state lamps and light-emitting modules, which is applied to lighting devices, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of insufficient thermal design, impracticality, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

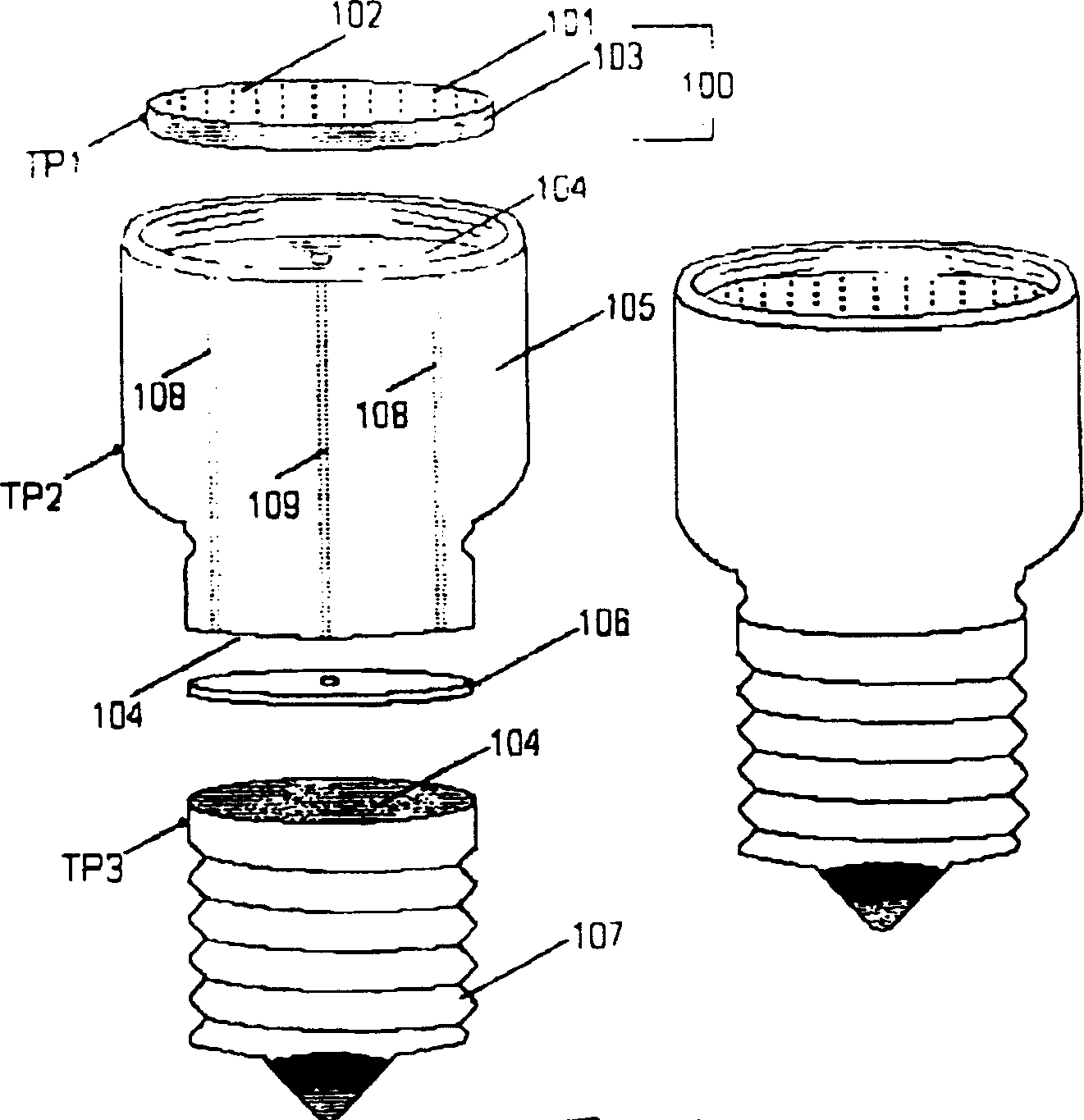

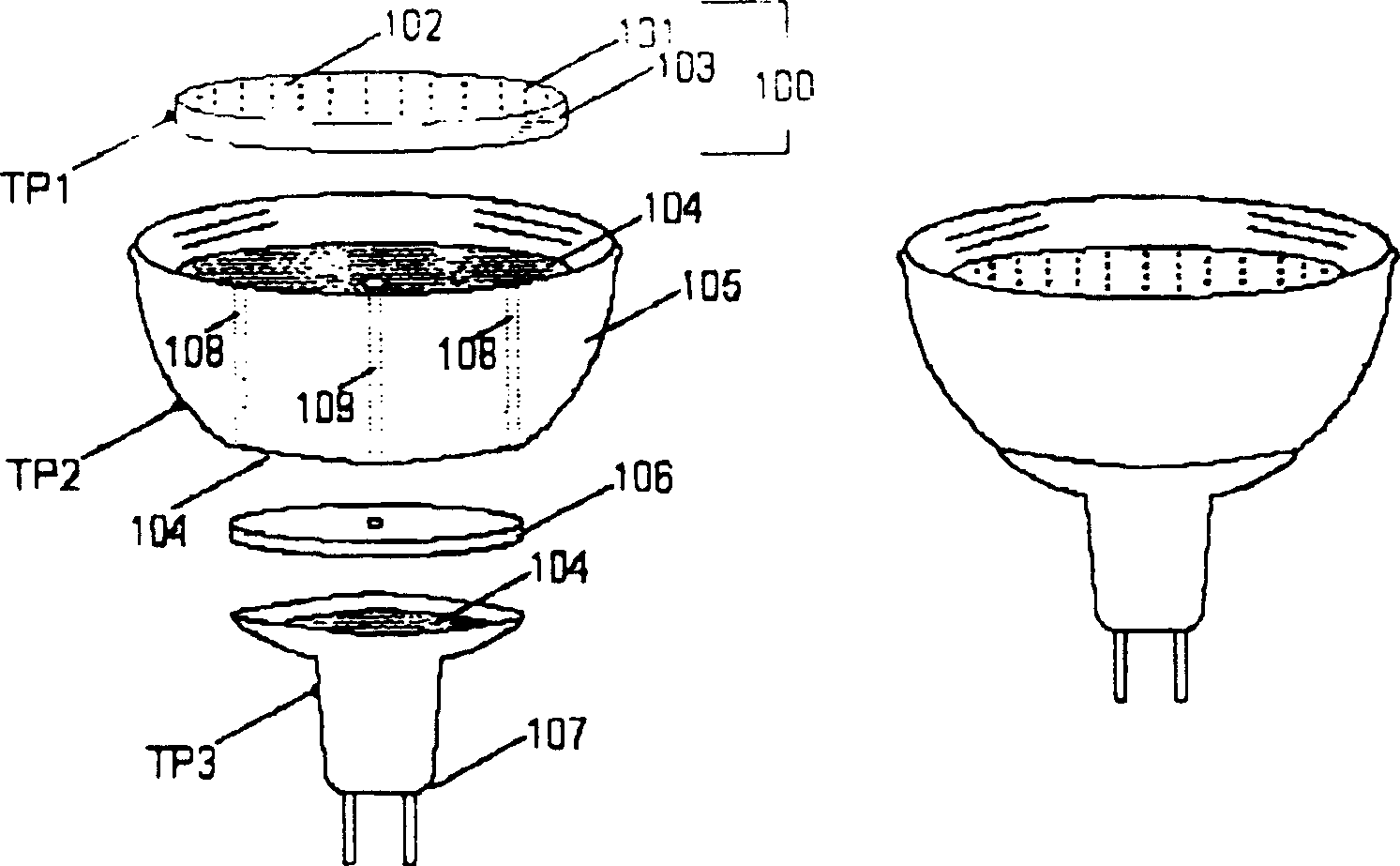

[0025] as attached Figure 1a , 2a , 3a and 5, a light emitting module (lighting module) 100 includes LED chips 101, and these LED chips 101 are directly fixed on a PCB (printed circuit board) using a traditional chip-on-board method known in the art. ) on 102. The PCB 102 is directly bonded to a backer plate / heat sink 103 made of aluminum, copper, ceramic or other materials with good heat transfer properties.

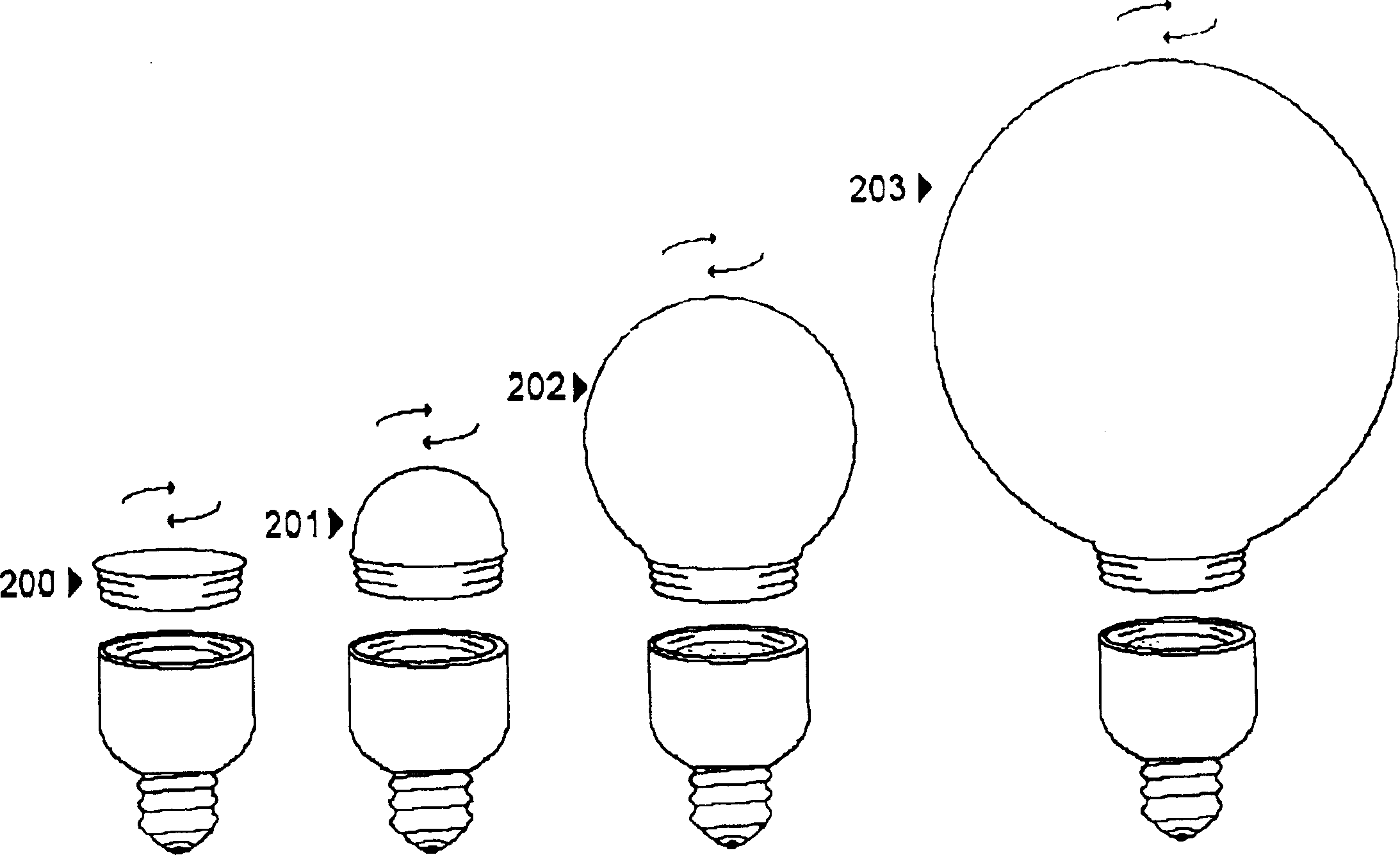

[0026] It should be noted that the total surface area of the light emitting module 100, especially the backing plate / heat sink 103 can be made smaller or larger and thicker to match the density and number of LED chips 101 and the total module power requirements (in watts) Unit) related thermal performance requirements. It should also be noted that the lighting module 100 can be fabricated using multiple planes that are electrically connected together. Test samples made using circular, single planar lighting modules exhibited uniform light distribution when fitted ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap