Electric furnace method yellow phosphorus tail gas residual heat comprehensive balance utilizing system

A comprehensive balancing and method of yellow phosphorus technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as corrosion and blockage, and achieve the effect of isolating high corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

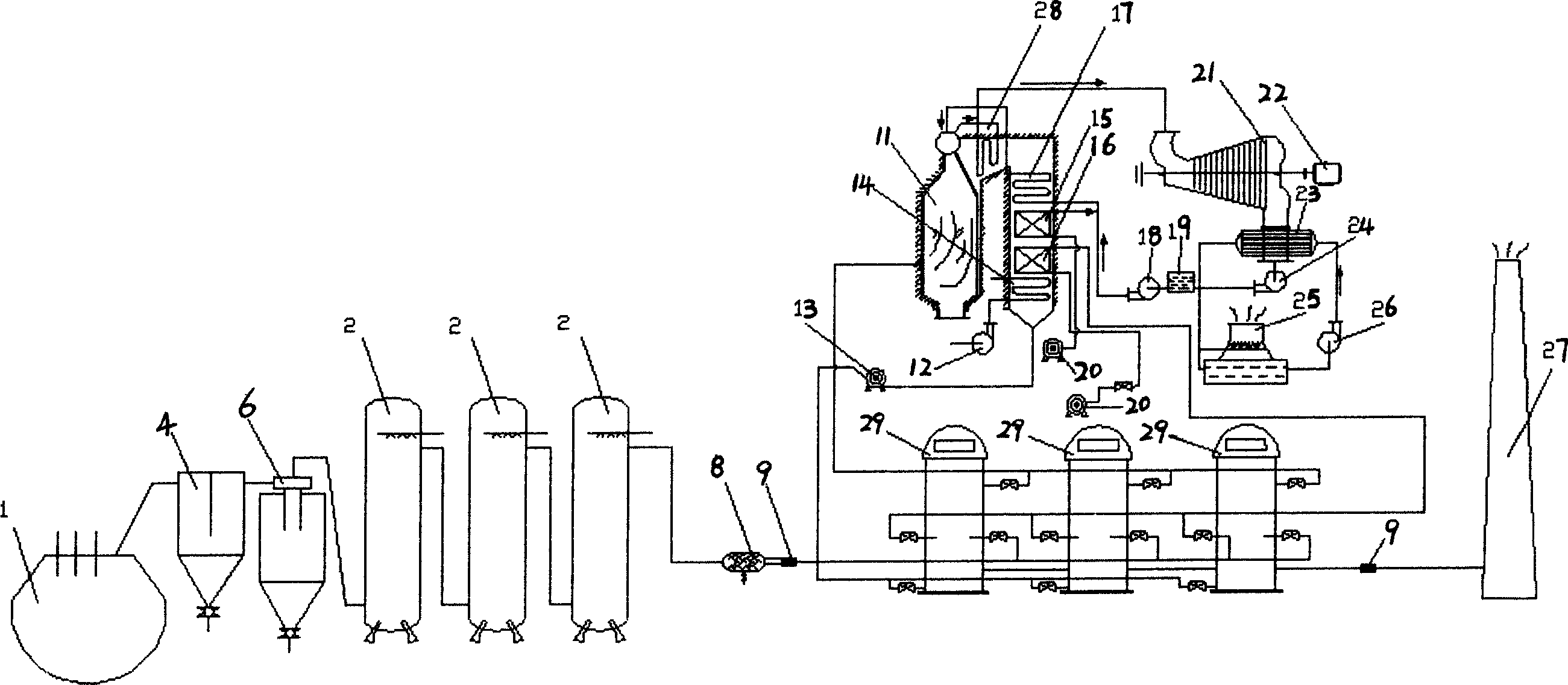

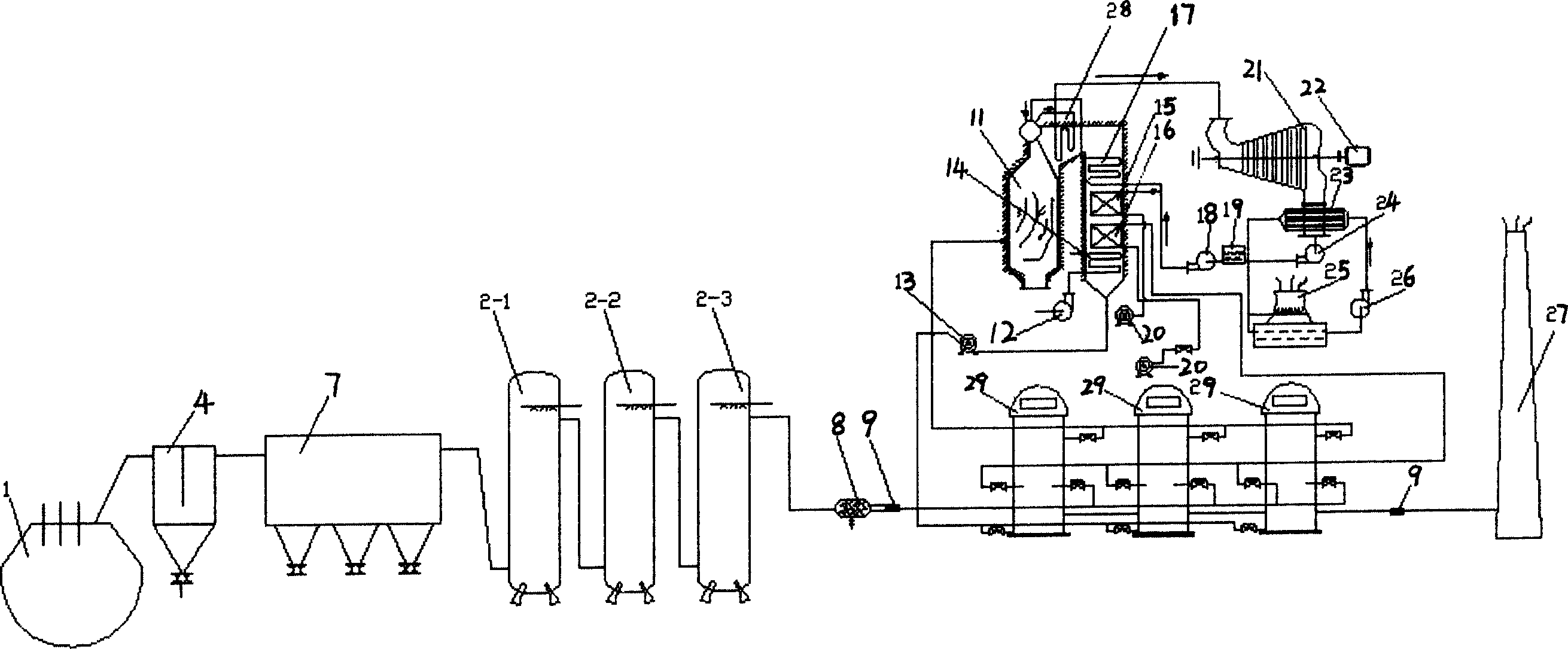

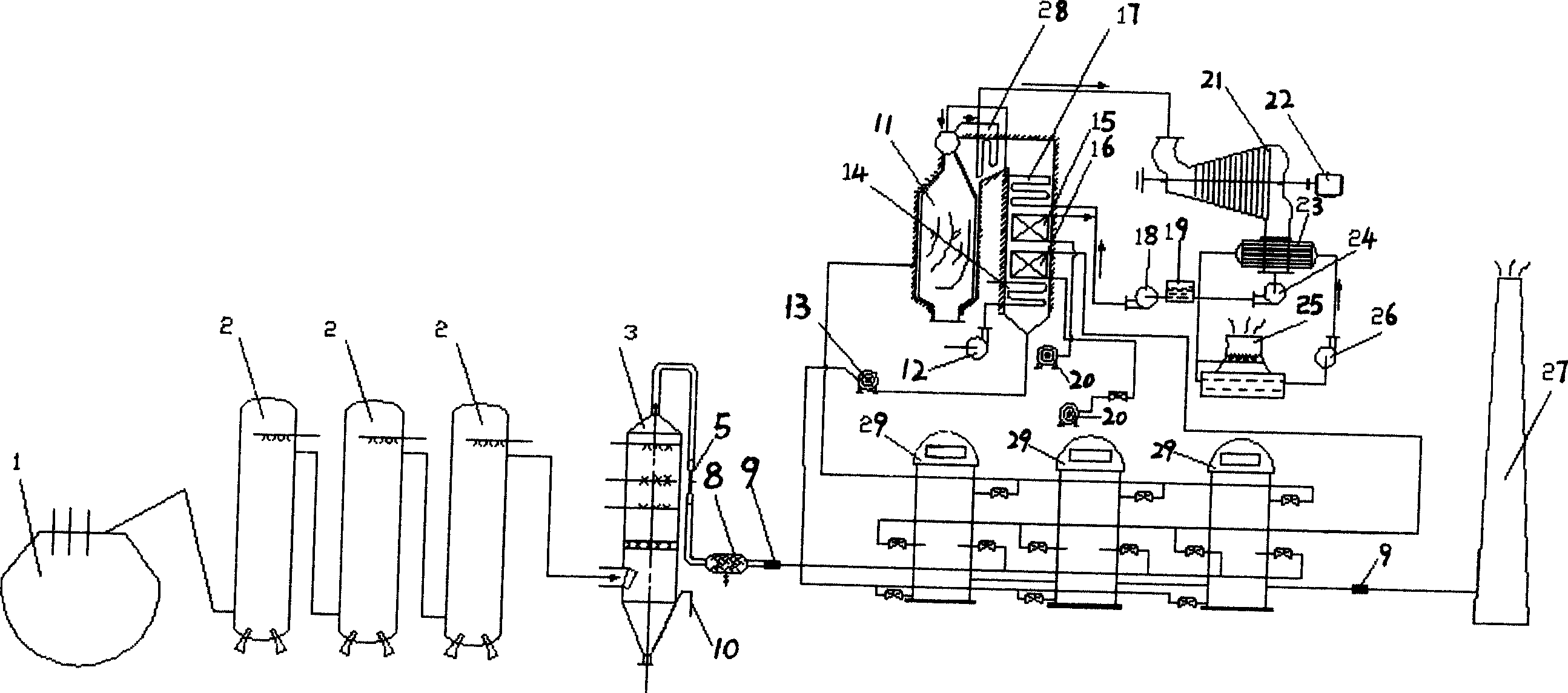

[0021] In the figure 1- yellow phosphorus electric furnace, 2- water spraying condensation tower, 3- washing tower, 4- settling chamber, 5- venturi scrubber, 6- cyclone dust collector, 7- bag filter, 8- yellow phosphorus tail gas Dehydrator, 9- yellow phosphorus tail gas preheater, 10- safety water seal, 11- waste heat boiler, 12- water pump, 13- induced draft fan, 14- hot water heater, 15- hot air heat exchanger, 16- air preheater Heater, 17-gas saving, 18-boiler feed pump, 19-water tank, 20-blower, 21-turbine generator, 22-generator, 23-condenser, 24-condensate pump, 25-cooling tower, 26 - cooling water pump, 27 - chimney, 28 - superheater, 29 - regenerative combustion heat exchange device.

[0022] The patented system is formulated in the following manner:

[0023] 1. Exhaust gas pretreatment and purification device

[0024] Yellow phosphorus tail gas contains CO, O 2 , CO 2 And other gases, with a lot of smoke and dust, the tail gas pretreatment and purification subsys...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap