Total pressure (direct) motor start control circuit

A technology of starting control and step-down starting, applied in the direction of motor generator/starter, starter of a single multi-phase induction motor, etc., can solve the problem of damage to the full-voltage starting control device of the motor, and increase the area of the arc extinguishing chamber. , Solve the effect of easy damage and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following specific embodiments are listed in conjunction with the accompanying drawings to further illustrate the technical solution of the present invention.

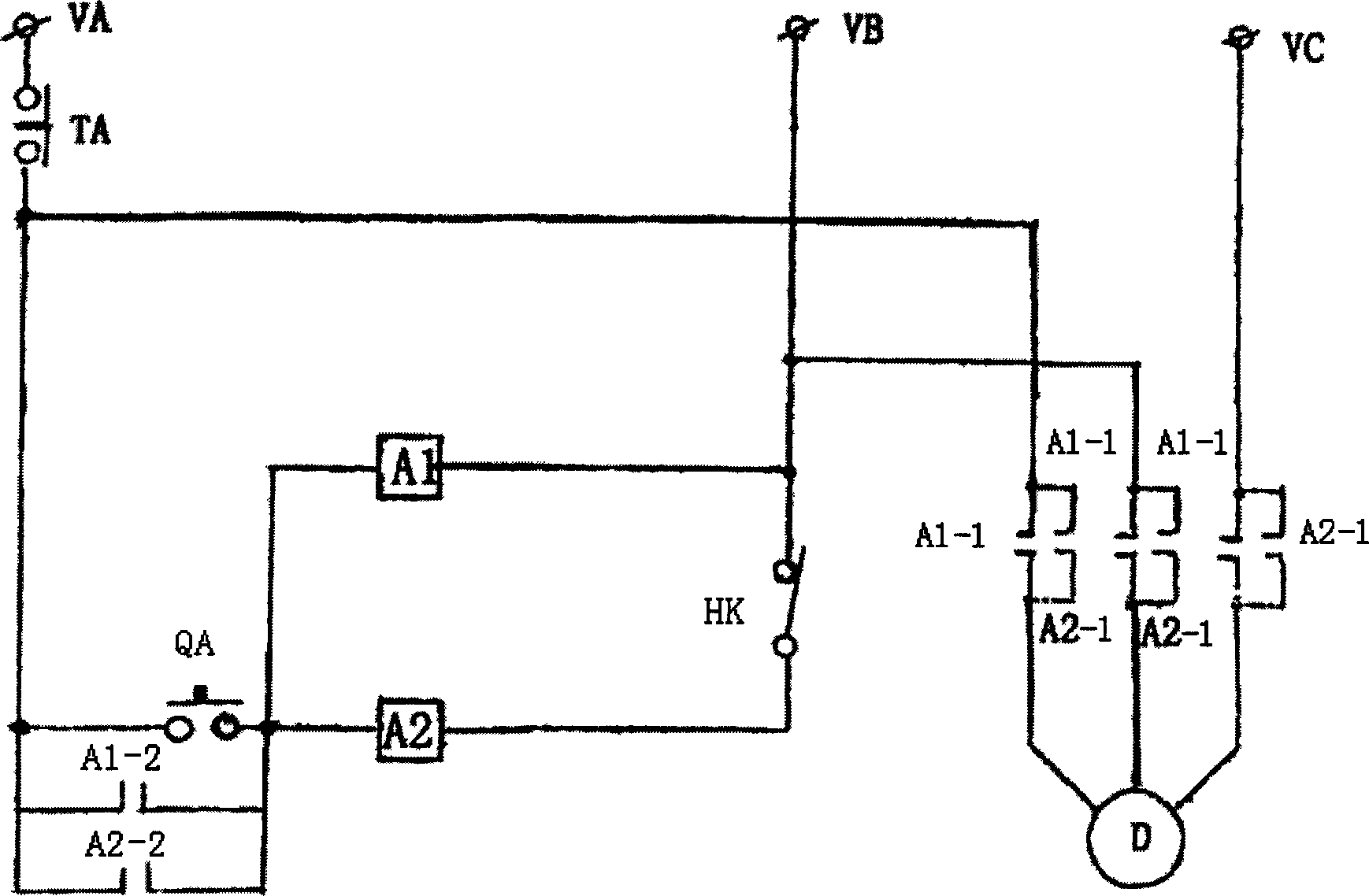

[0015] Embodiments of the present invention, such as figure 1 The full voltage (direct) motor starter control circuit shown. The full voltage (direct) motor starting control circuit is composed of TA stop button, QA start button, HK switch, A1 contactor and A2 contactor. The other end is connected to one end of the QA start button, the other end of the QA start button is connected to one end of the parallel A1 contactor and A2 contactor, A1 contactor auxiliary contact A1-2 and A2 contactor auxiliary contact A2- 2. Parallel connection with both ends of the QA start button, the other end of the A2 contactor is connected to the power supply VB by the HK switch and the other end of the A1 contactor, and the A1 contactor and A2 contactor control the motor start, which has full voltage (direct) start It has the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com