Electricity saving device of full automatic three-phase motor

A three-phase motor, fully automatic technology, applied in the direction of adjusting electrical variables, AC motor control, instruments, etc., can solve problems such as incomplete use and semi-automation, and achieve the effect of reducing voltage and current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

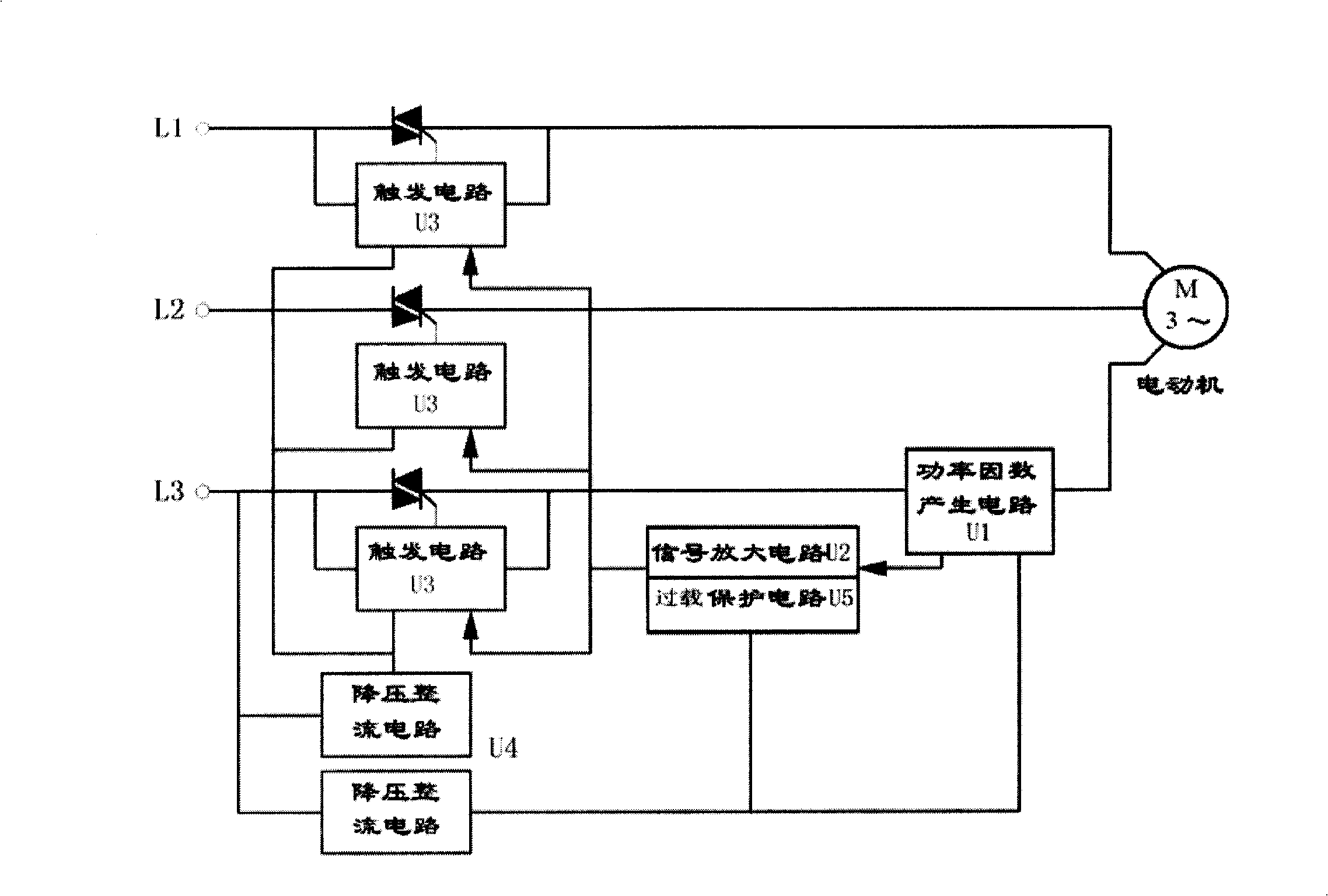

[0011] refer to figure 1 , fully automatic three-phase motor power saver, including power factor generating circuit U1, signal amplifying circuit U2, trigger circuit U3 and bridge rectifier circuit group U4, the input end of power factor generating circuit U1 is connected with three-phase power L1, L2, L3, The output end of the power factor generation circuit U1 is connected to the signal amplifier circuit U2, the output end of the signal amplifier circuit U2 is connected to the trigger circuit U3, the three-phase power L1, L2, L3 is connected to the three-phase motor after passing through the trigger circuit U3, and the bridge rectifier circuit group U4 They are respectively connected to the power input terminals of each circuit.

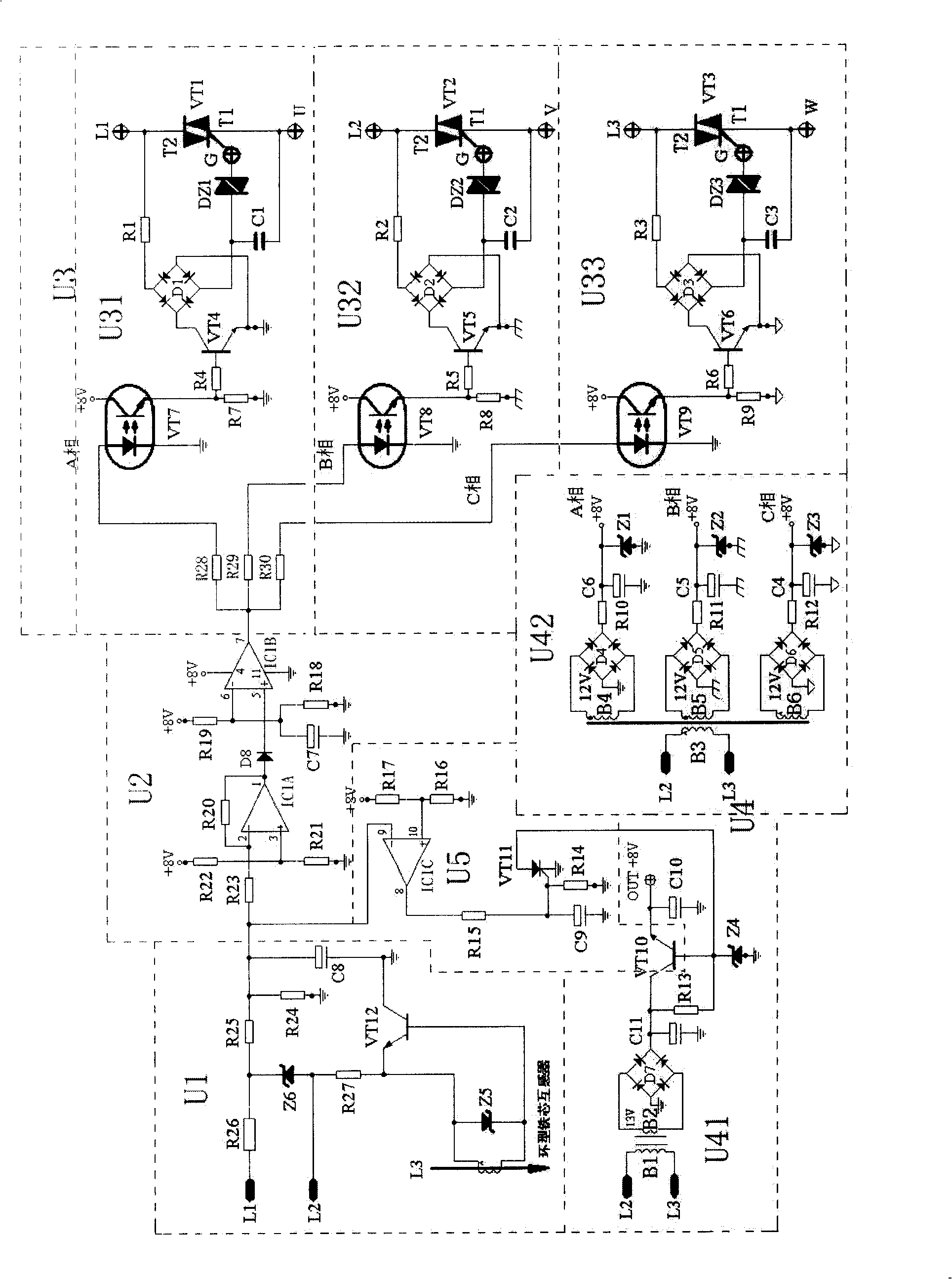

[0012] Refer below figure 2 The composition and principle of each resistor are described in detail.

[0013] (1) The power factor generation circuit U1 is used to detect the change of the power factor of the three-phase motor. It is a three-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com