Method for making elastic caterpillar and sulfurization forming apparatus using said method

A manufacturing method and vulcanization molding technology, applied in applications, belts, household appliances, etc., can solve problems such as inability to ensure adhesion and breakage, and achieve the effect of ensuring adhesion and strong vulcanization bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

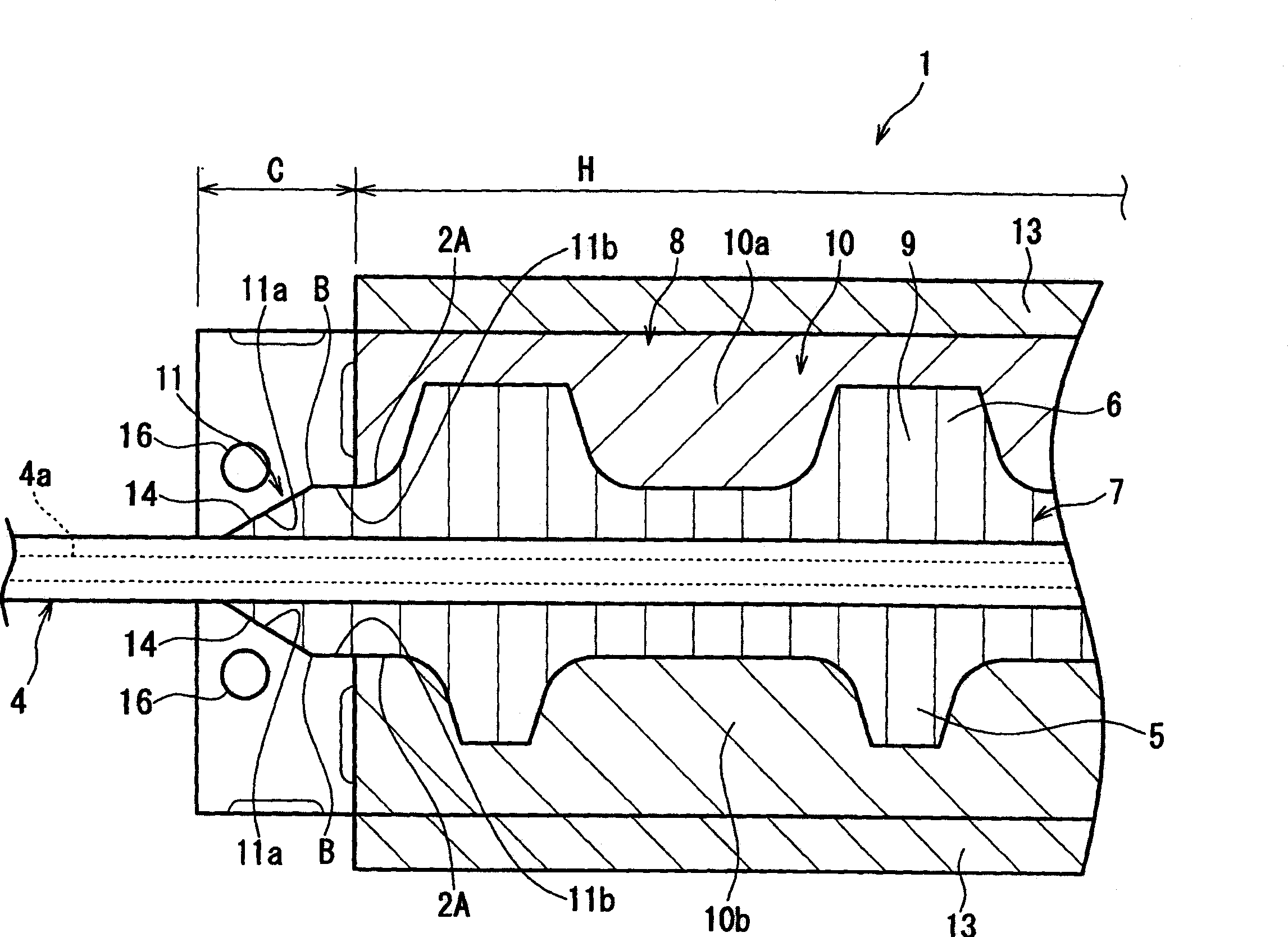

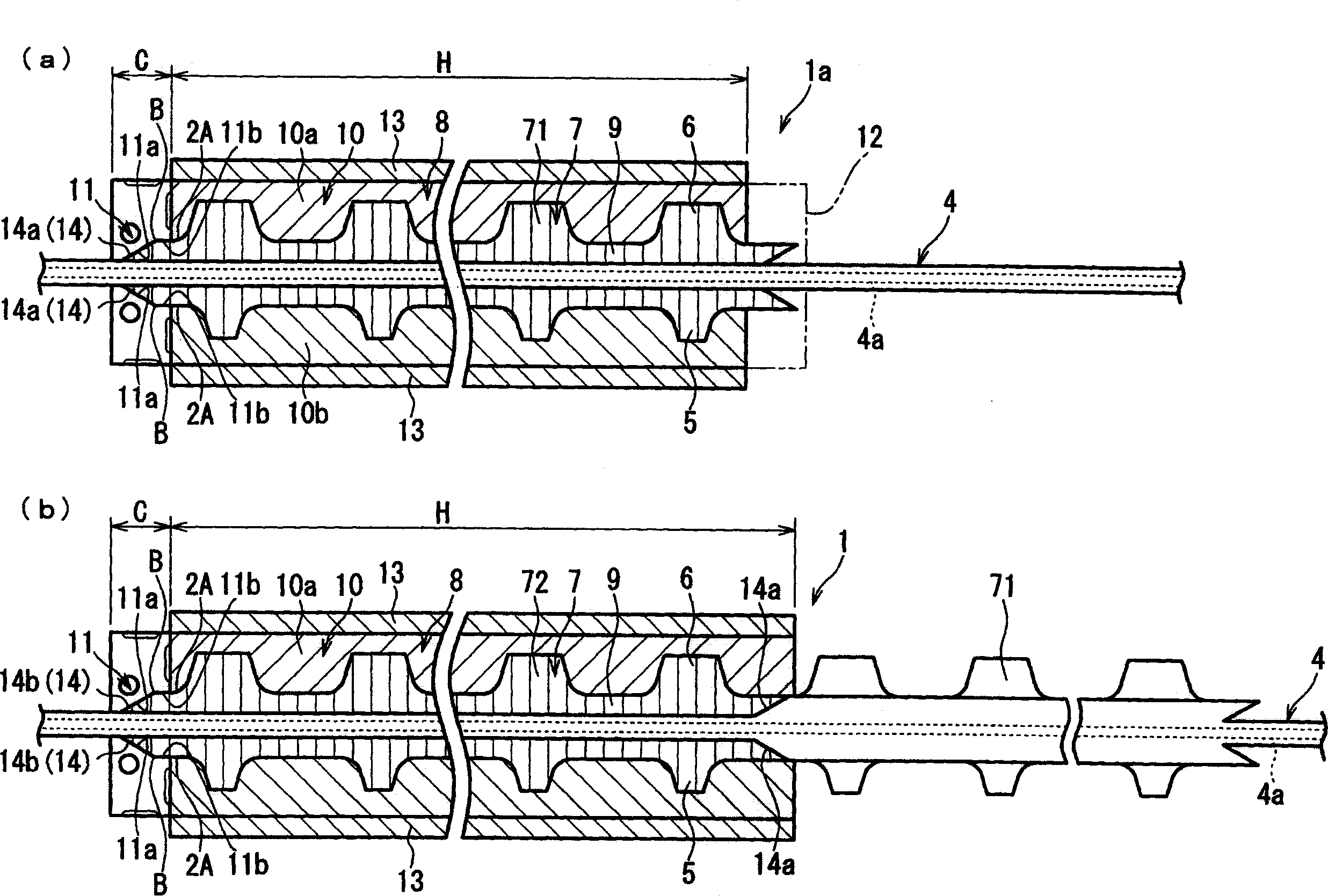

[0030] Embodiments of the present invention will be described below with reference to the drawings.

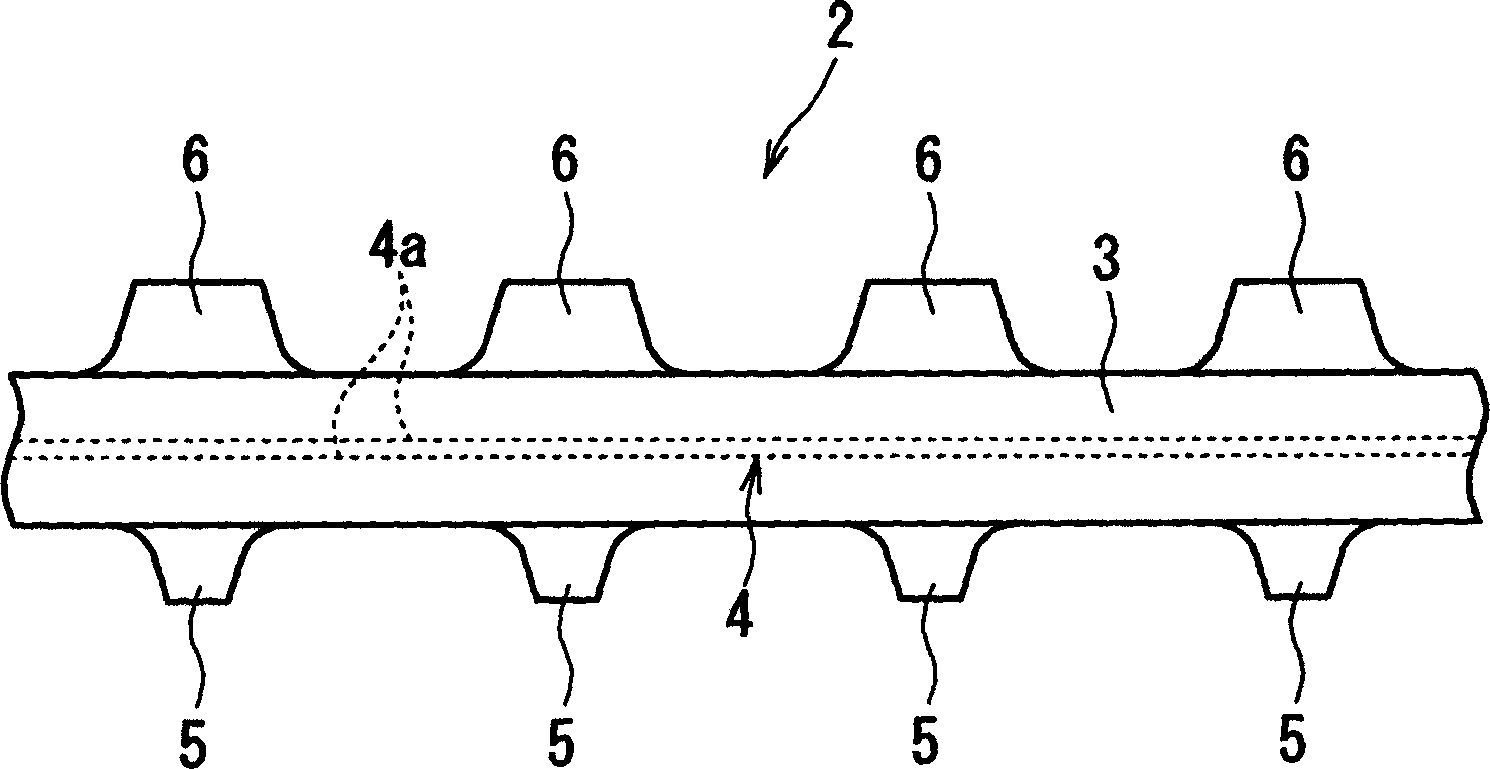

[0031] figure 1 It shows the vulcanization molding apparatus 1 using the elastic crawler manufacturing method related to the first embodiment of the present invention, figure 2 The elastic crawler belt 2 which is a product manufactured by the vulcanization molding apparatus 1 is shown. in addition, figure 1 The left and right directions of the figure 1 same.

[0032] like figure 2 As shown, the elastic crawler 2 is an elastic crawler used in a crawler-type traveling device such as a combine harvester or a harvester, and has a crawler main body 3 formed of an elastic rubber material in a jointless shape, a steel rope buried in the crawler main body 3, and the like. The anti-expansion body 4, the driving protrusion 5 protruding from the inner peripheral side (lower side in the figure) of the crawler main body 3, and the flange 6 protruding from the outer peripheral side (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com