Wiper control method

A device control and wiper technology, which is applied in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., can solve problems such as damage to wiper arms, connecting rods, and motors, and achieve the effect of ensuring vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

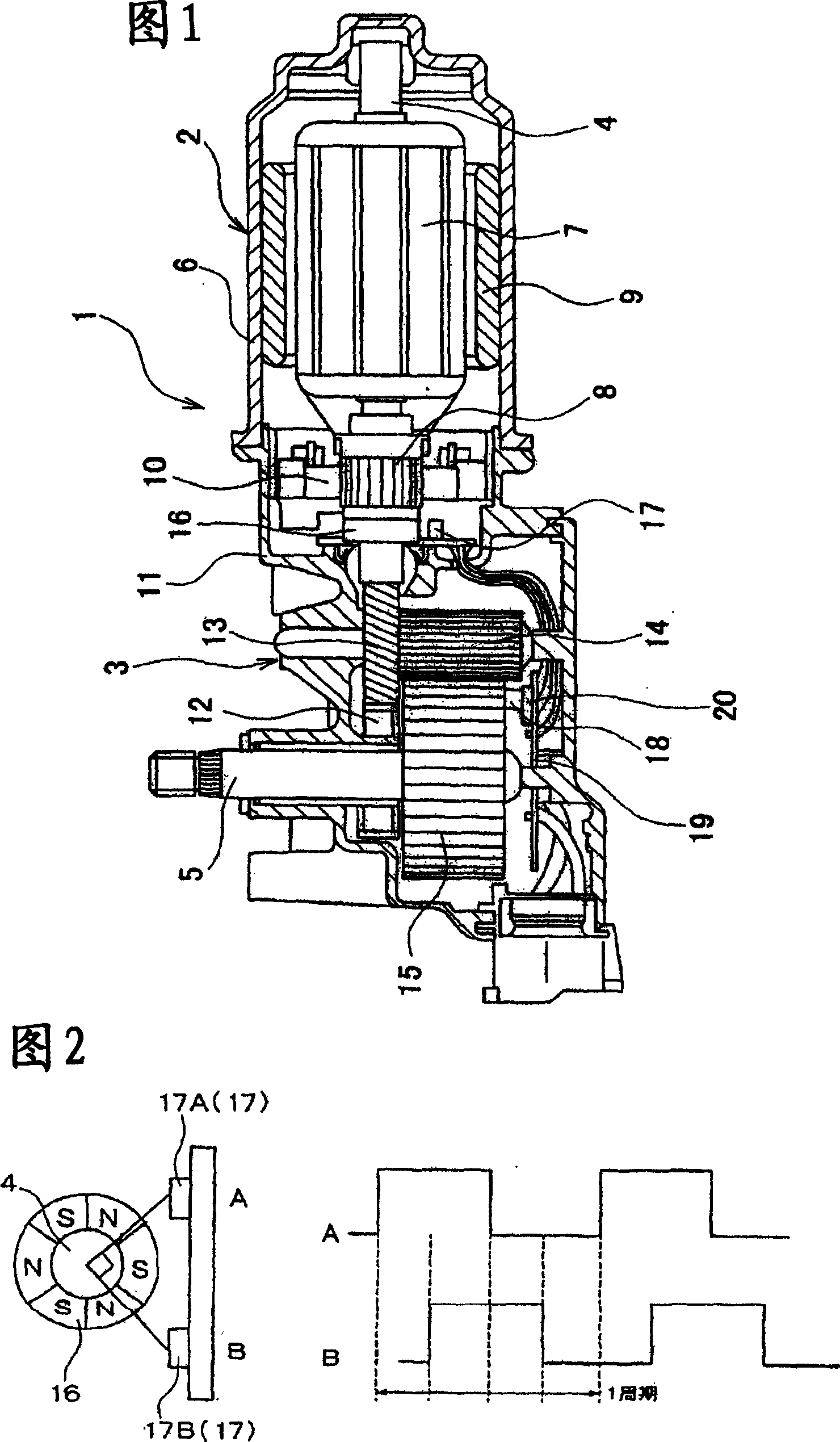

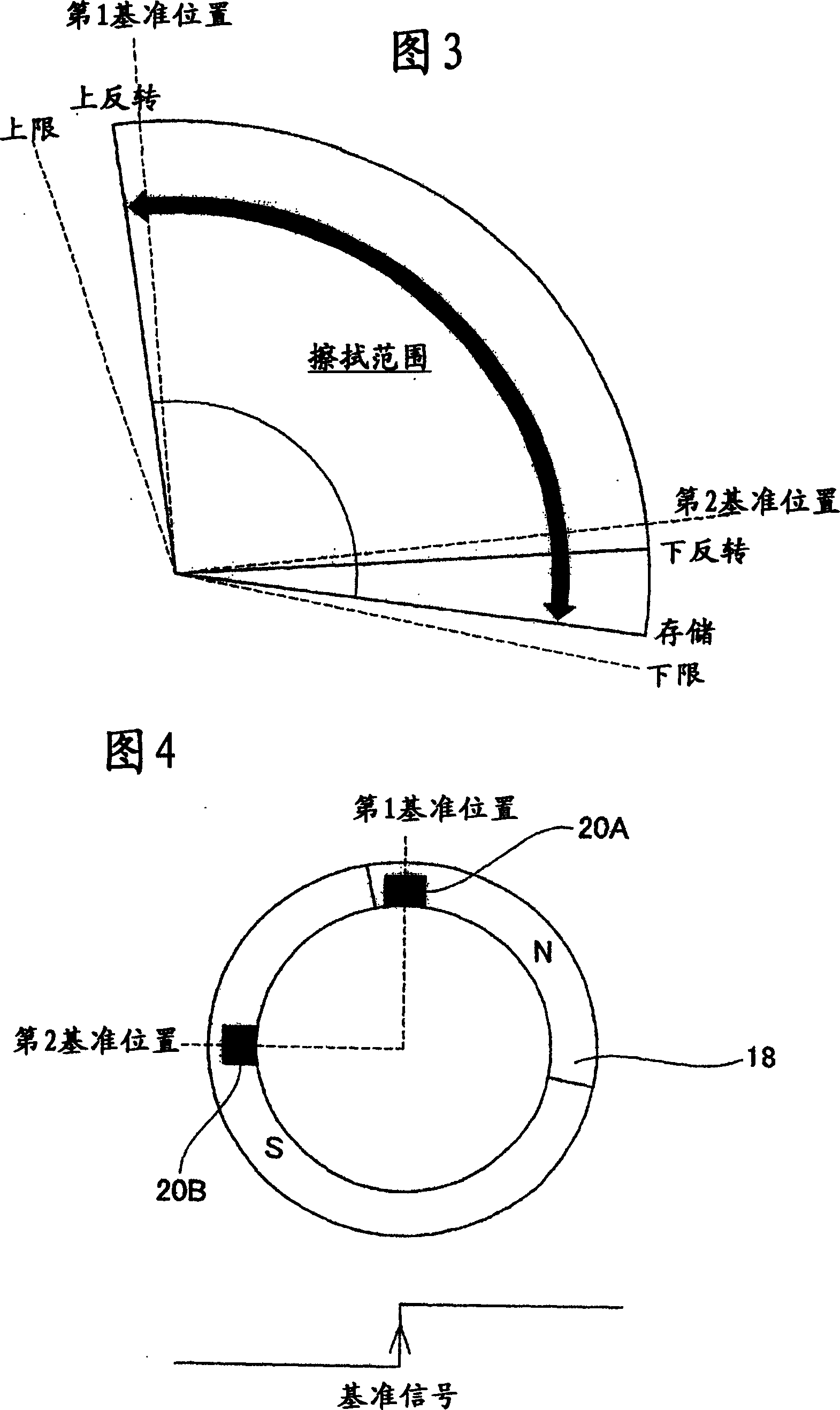

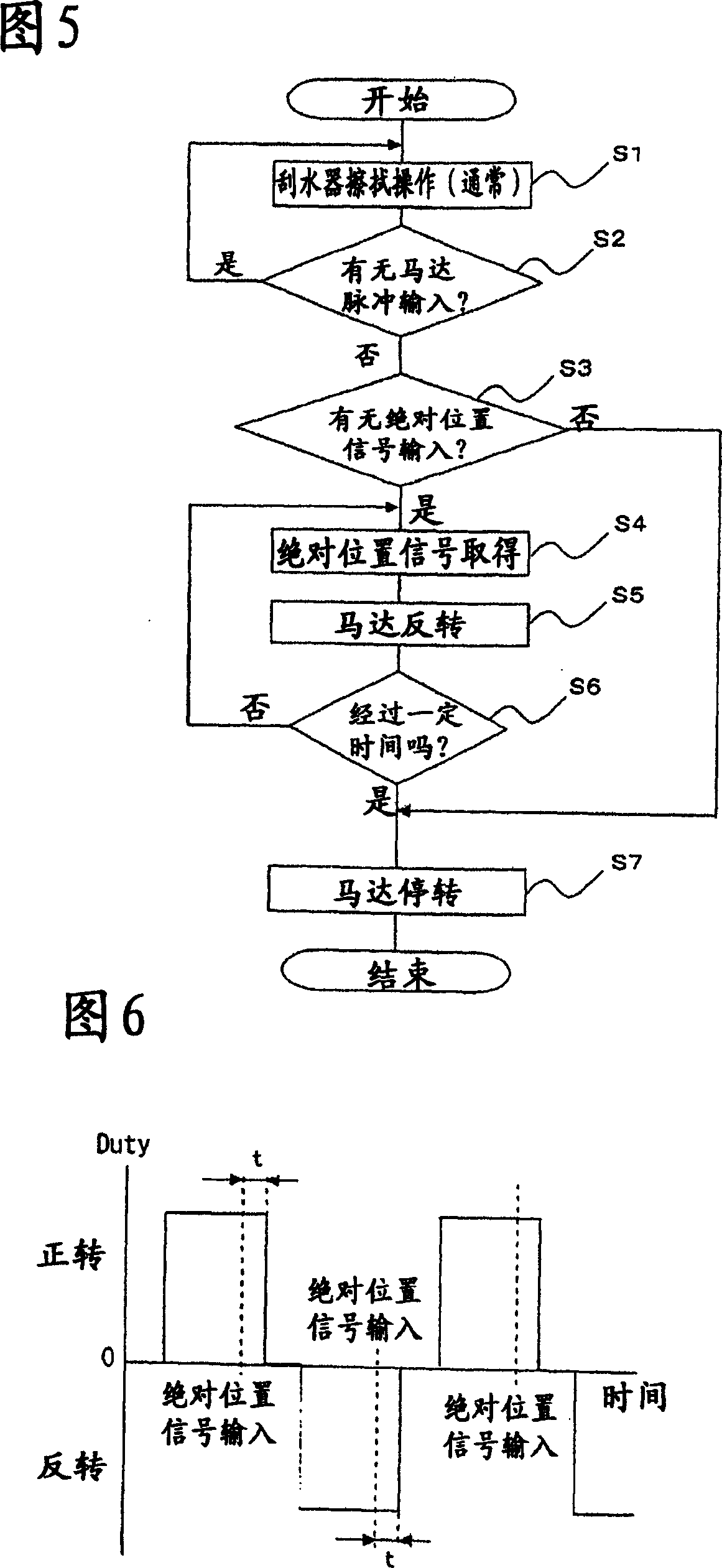

[0040] FIG. 1 illustrates the structure of a motor unit having a motor applicable to a method of controlling a wiper device according to Embodiment 1 of the present invention. The motor unit 1 of FIG. 1 is used as a drive source of a facing wiper device (opposed type) in which respective motors drive respective wiper arms (hereinafter simply referred to as arms) on the driver's seat side and the passenger's seat side. The arm in the motor unit 1 can change the direction of rotation when it reaches the up and down reverse position.

[0041] The motor unit 1 is composed of a motor 2 and a gear box 3 , the rotating shaft 4 of the motor 2 is decelerated in the gear box 3 and output to the output shaft 5 . The rotating shaft 4 freely rotates in a bottomed cylindrical yoke 6 through a bearing, and an armature core 7 wound with a coil and a commutator 8 are installed, and a plurality of permanent magnets are fixed on the inner surface of the yoke 6 . The commutator 8 is in sliding c...

Embodiment 2

[0061] Next, the control method of the wiper device according to Embodiment 2 of the present invention will be described. FIG. 7 is a flow chart showing its processing steps. This control method is also the same as that of Embodiment 1, and is implemented in the motor unit 1 of FIG. 1 . In addition, in the following embodiments, the same components and parts as those in the first embodiment are given the same reference numerals and their descriptions are omitted.

[0062]In Embodiment 2, step S11 is a normal wiper control process, based on the absolute position signal and the position of the motor pulse detection arm, the forward and reverse rotation of the motor is controlled to perform the reverse wipe operation of the wiper blade. Same as the situation in Embodiment 1, while performing this normal control, monitor whether there is a motor pulse input in step 12, if there is a motor pulse input, then continue the normal control (S11), if there is no input, then proceed to S...

Embodiment 3

[0069] Now, the control method of the wiper device according to Embodiment 3 of the present invention will be described, and FIG. 9 is a flow chart showing its processing steps. In Embodiment 3, step 31 is a normal wiper control process, which detects the position of the arm through the absolute position signal and the motor pulse to perform the reverse wipe operation of the wiper blade, and executes the forward and reverse control of the motor. While carrying out this normal control, same as the situation of embodiment 1, monitor whether there is the input of motor pulse in step S32, can continue normal control (S31) when there is the input of motor pulse, and when there is no motor pulse 20 When it is input, it proceeds to step S33 and the following steps, and executes exception handling.

[0070] In step S33, regardless of the current rotation direction and position, no matter what the situation is, when the motor 2 is in the forward rotation direction (for example, the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com