Ordered rice-husking process and machine

A technology of rice milling machine and rice milling roller, which is applied in the direction of grain processing, application, grain pod removal, etc., to achieve the effect of reducing mutual extrusion and collision, improving efficiency, and increasing the milling surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] This embodiment is only used to illustrate the technical solution of the present invention, and its structure is not limited to the structure of this embodiment.

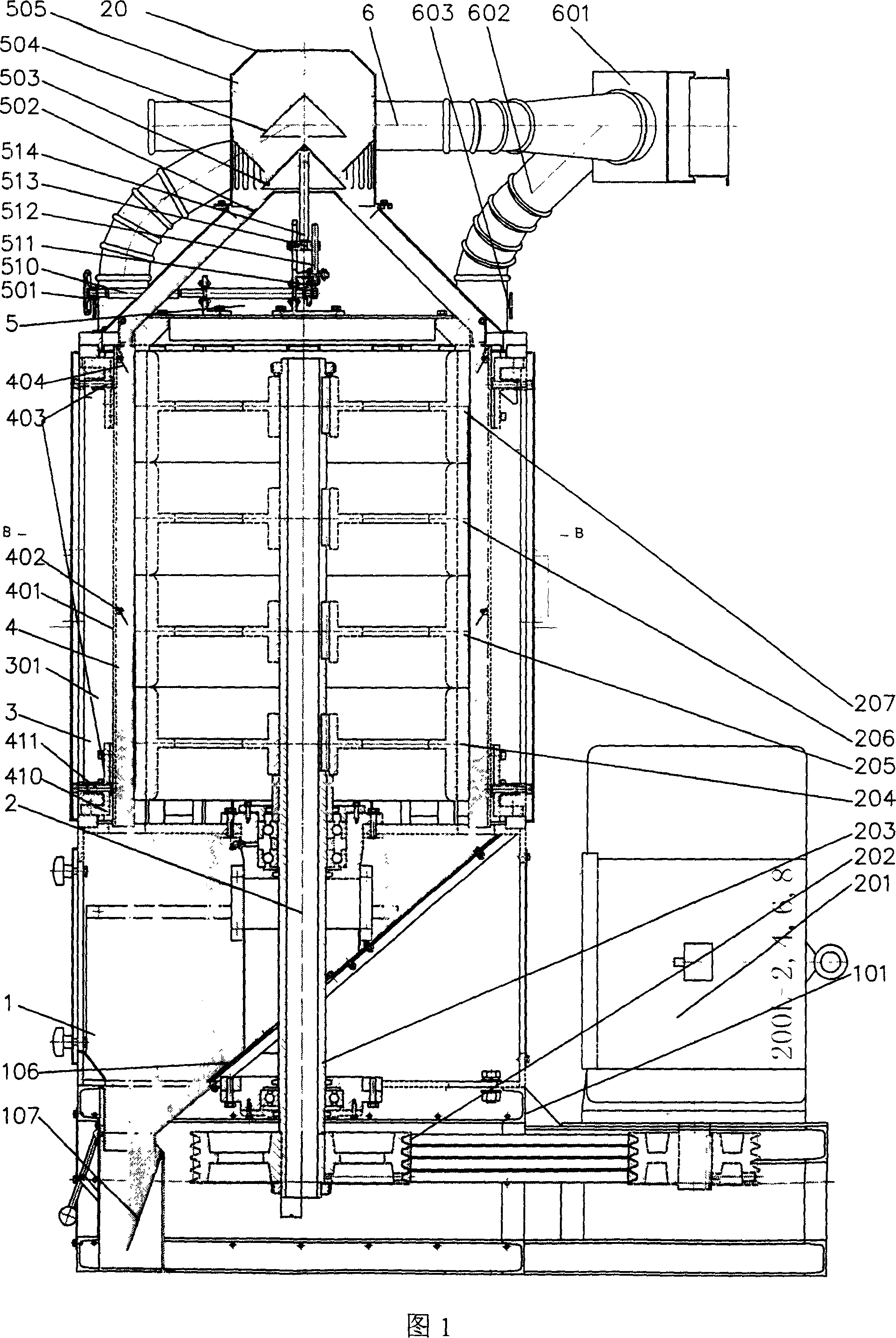

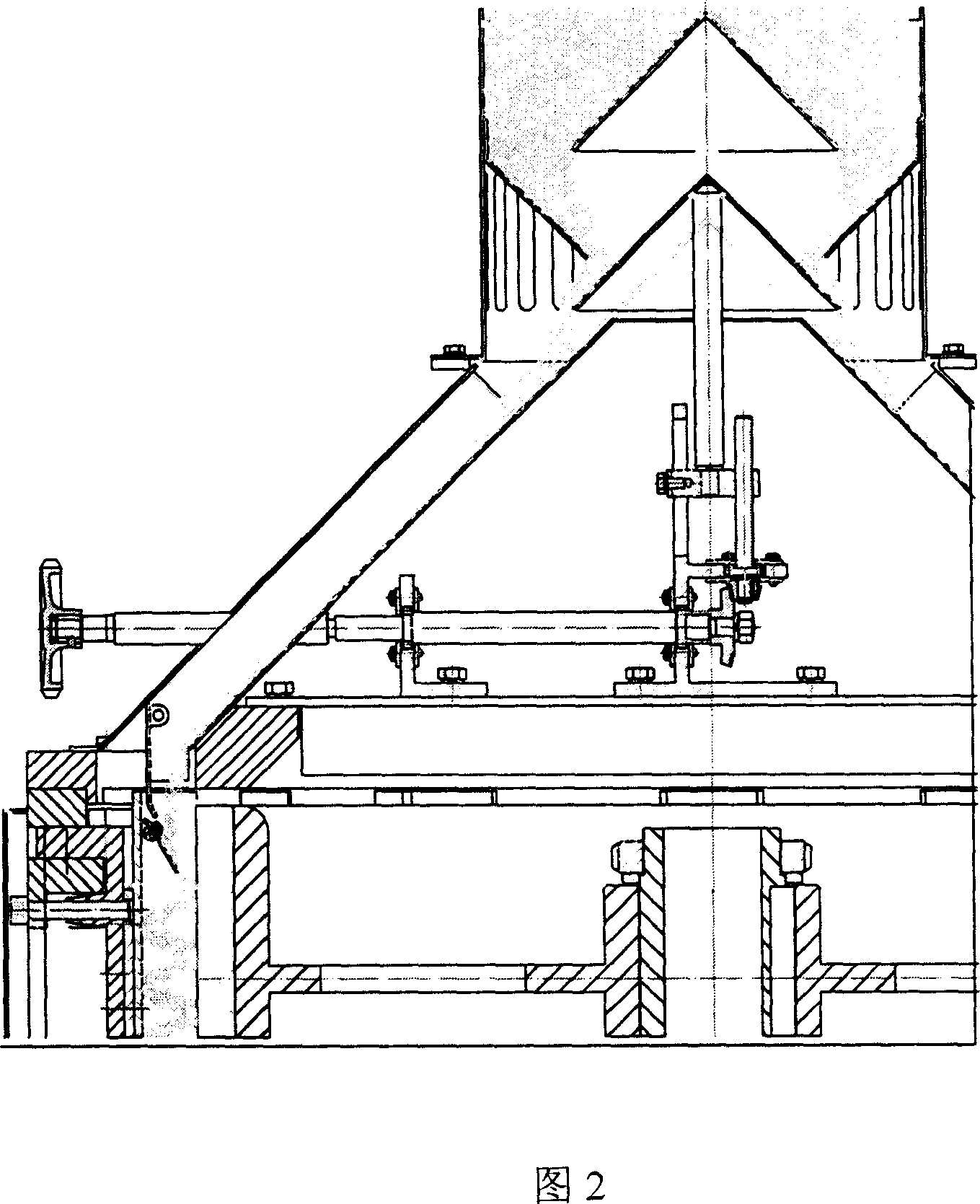

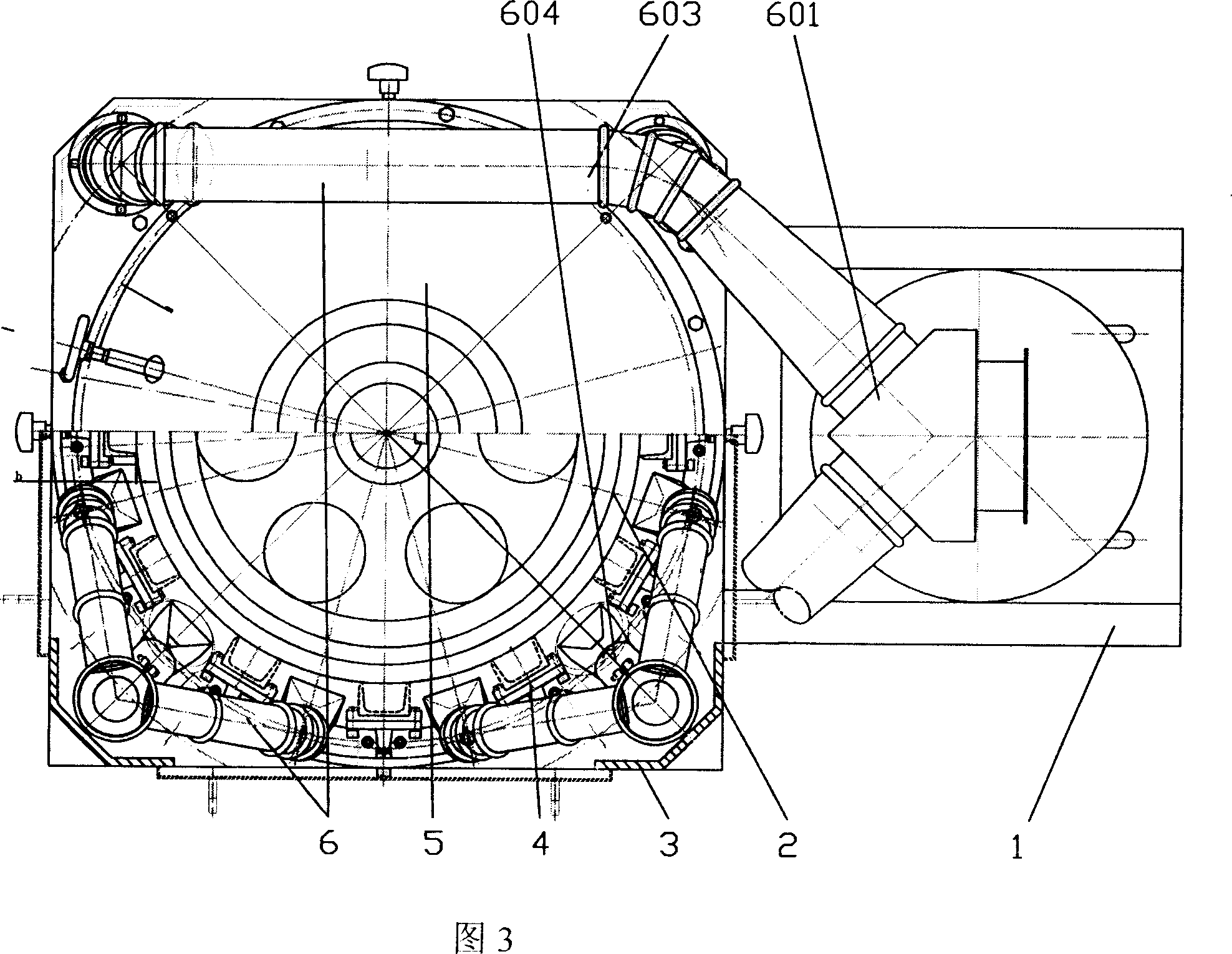

[0011] As shown in Figure 1, a body is provided on the machine base 101, and the body is divided into an upper body 3 and a lower body 1, and a discharge device is arranged in the lower body 1, and the discharge device includes a discharge flow plate 106, and the discharge flow plate 106 is provided with a The discharge flow plate 107, the discharge flow plate 107 is located at the discharge port. Rice milling roller device is established in upper machine body 3, and rice milling roller device comprises multi-section emery wheel 204,205,206,207 vertically arranged; Rice milling roller device is connected with rice milling roller rotary transmission mechanism 2, and rice milling roller roller The rotation transmission mechanism includes a main shaft 203 connected with the grinding wheel, a belt transmission de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com