Telescopic actuator with a main rod and an auxiliary rod, and method applying said actuator

A technology of auxiliary rods and actuators, which is applied in the directions of transmission, transportation and packaging, belts/chains/gears, etc., and can solve problems such as safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

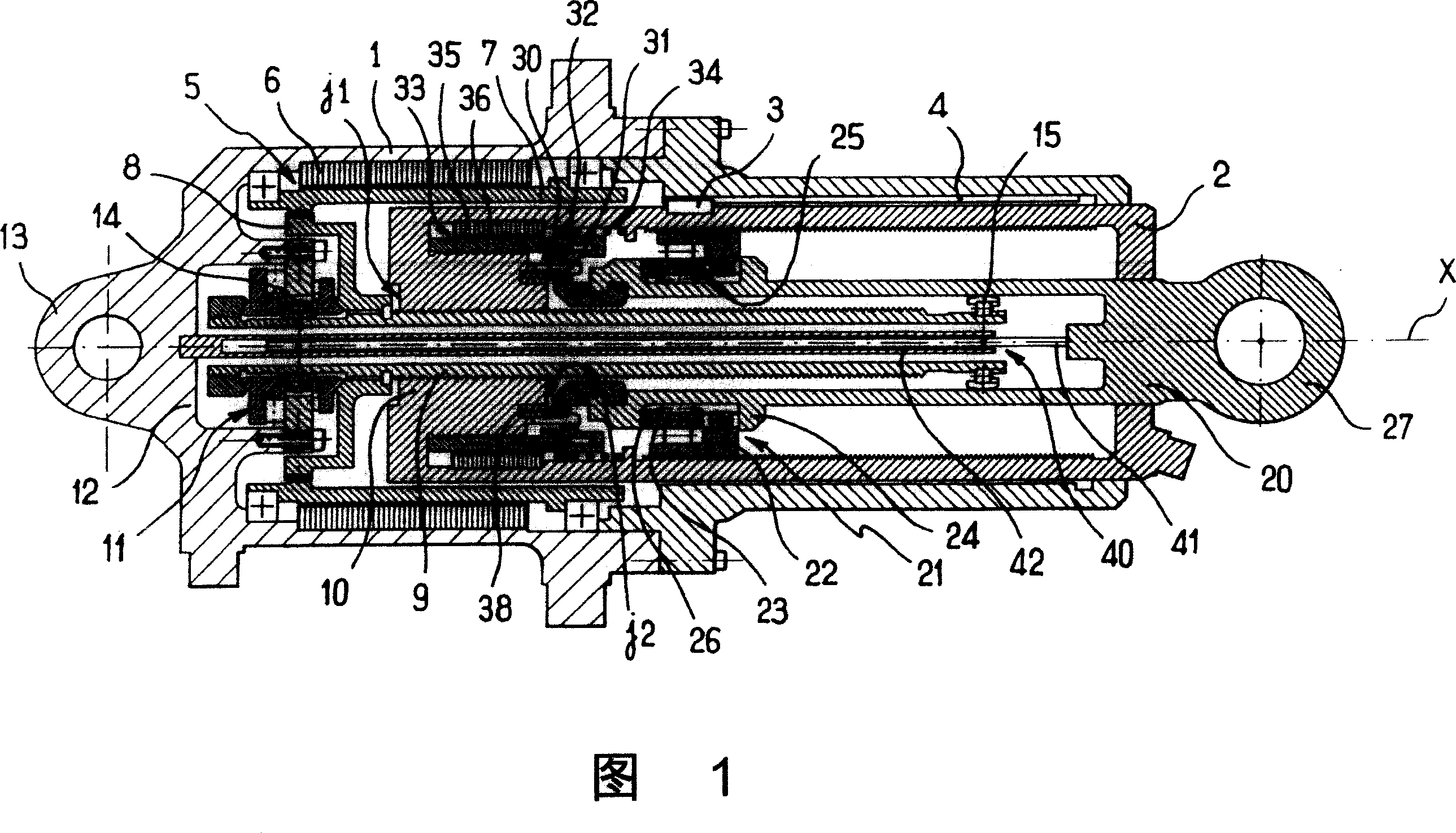

[0020] Referring to FIG. 1 , in a particular embodiment of the invention, the actuator comprises a barrel 1 forming a cylindrical interior closed by an end wall 12 with a lug 13 . A main rod 2 is mounted in the cavity for sliding along a sliding axis X and protrudes from the cylinder 1 to a greater or lesser extent through the open end of the cylinder constituting a bearing.

[0021] The actuator comprises control means for controlling the sliding of the main rod 2 relative to the cylinder 1 . The slide controls include:

[0022] - a key 3, fixed to the main rod 2 and cooperating with a groove 4 formed in the wall of the inner cavity of the cylinder 1, to prevent the rotation of the main rod 2 relative to the cylinder 1;

[0023] - a drive motor 5 comprising a stator 6 mounted stationary in the cylinder 1, and a rotor 7 mounted in the cylinder 1 in rotation about the axis X;

[0024] - A lead screw 9 extending along the axis X, mounted for rotation about the axis X in the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com