Multipurpose blind cutting machine

a cutting machine and multi-purpose technology, applied in the field of venetian blinds, can solve the problems of less efficient cutting method, high production of dust, and inconvenient cutting, and achieve the effect of less floor installation spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

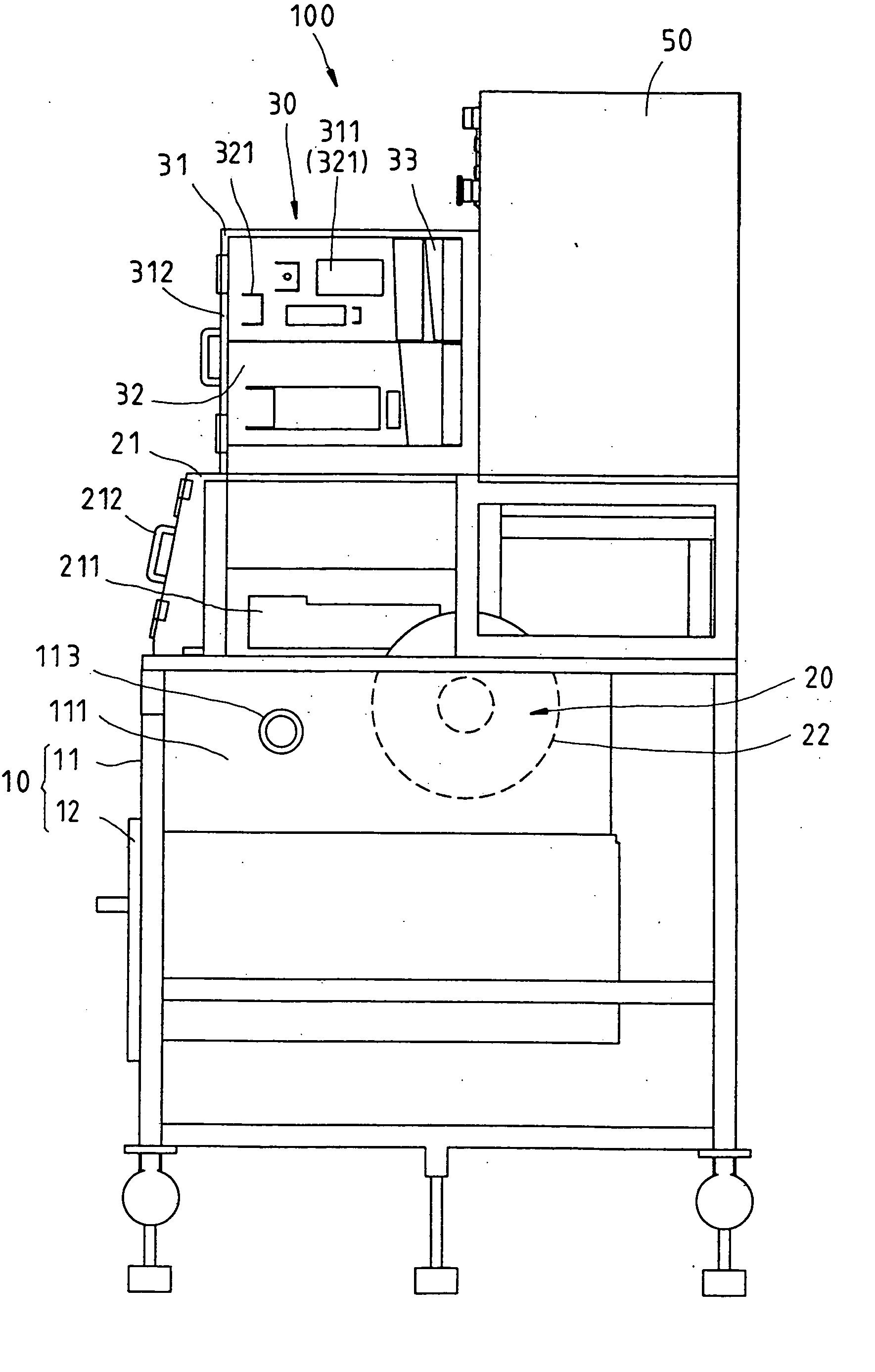

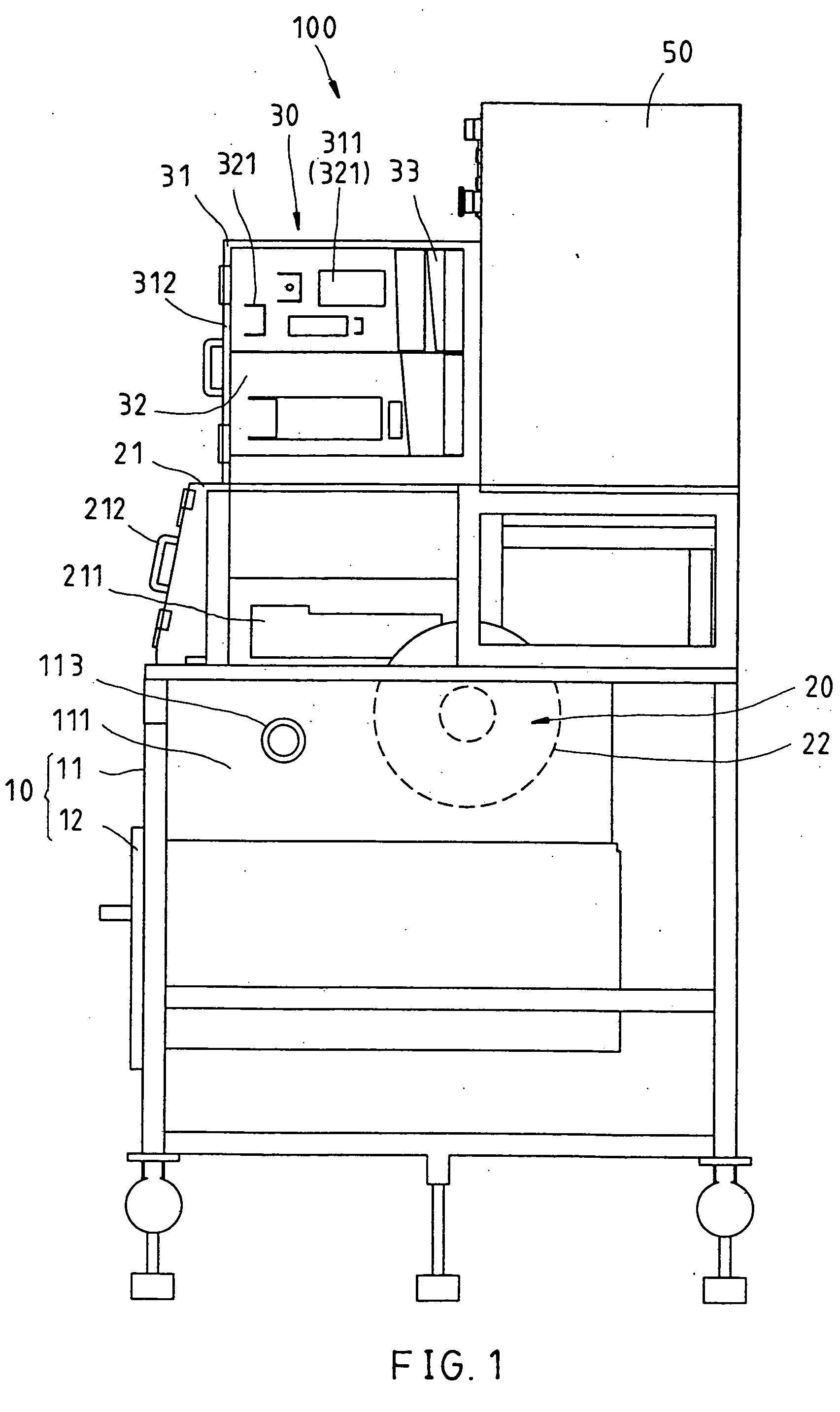

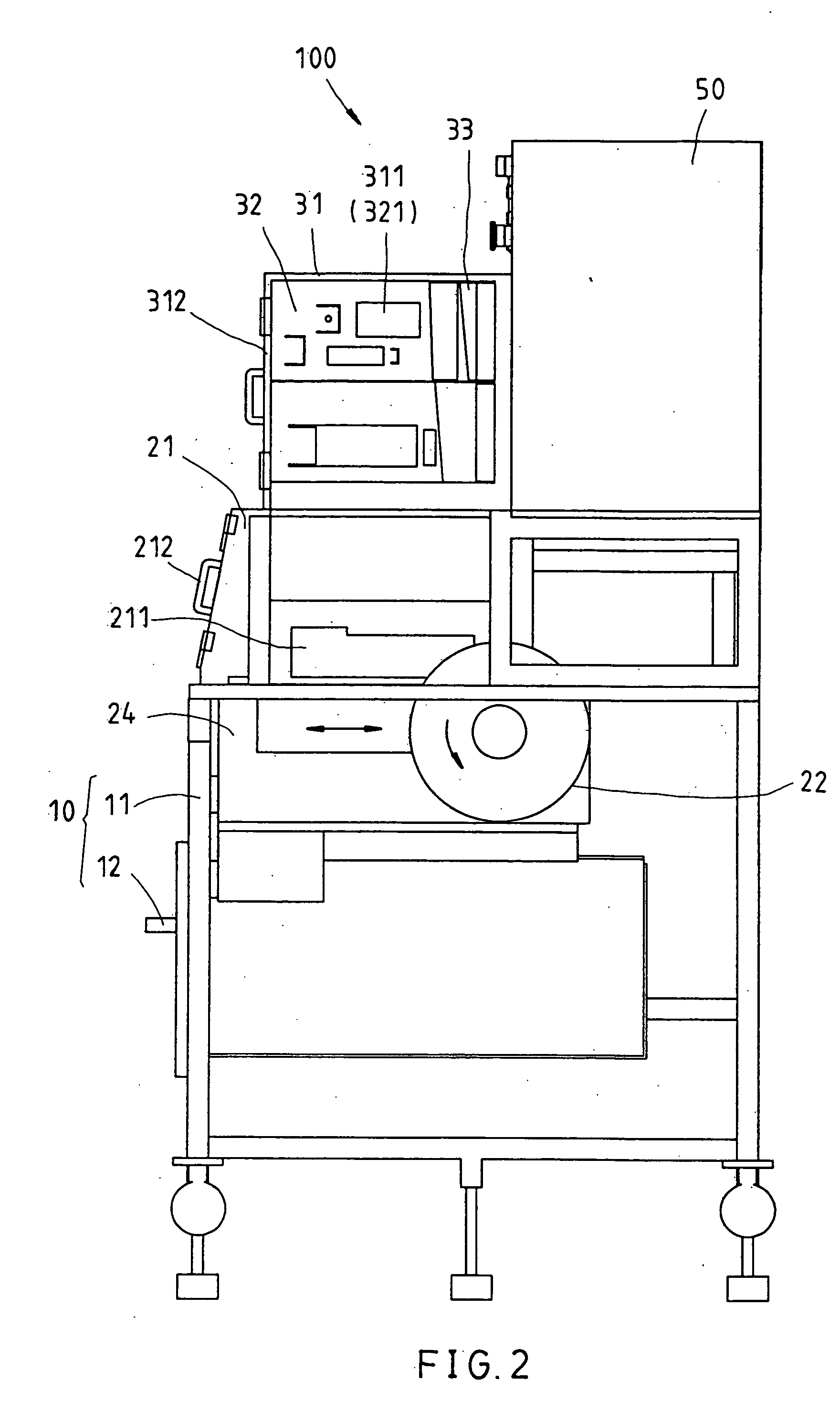

[0016] Referring to FIGS. 1˜7, a multipurpose blind cutting machine 100 is shown comprised of a machine base 10, a first cutter unit 20, a second cutter unit 30, a waste material separator 40, and a control unit 50.

[0017] The machine base 10 can stably be positioned on the floor, comprising a worktable 11 and a material basket 12. The worktable 11 is a four-leg table. Preferably, the four sides of the four-leg table of the worktable 11 are blocked with peripheral walls, defining a rectangular open space having top and bottom sides opened. The worktable 11 has two shielding boards 111 bilaterally suspended near the bottom open side (see FIG. 4), two guide rails 112 respectively provided at the bottom sides of the shielding boards 111, and a dust hole 113 in one shielding board 111 for holding a dust collector (not shown) adapted to collect dust and waste material chips produced from a blind cutting operation of the multipurpose blind cutting machine. The material basket 12 is mounte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com