Spin controlling golf club impact faceplate

a golf club and faceplate technology, applied in the field of golf club head and face construction, can solve problems such as ball veering left or righ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

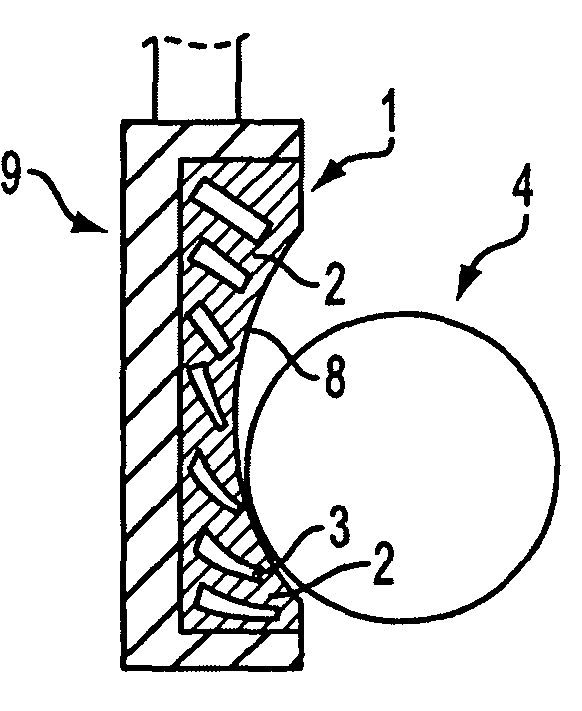

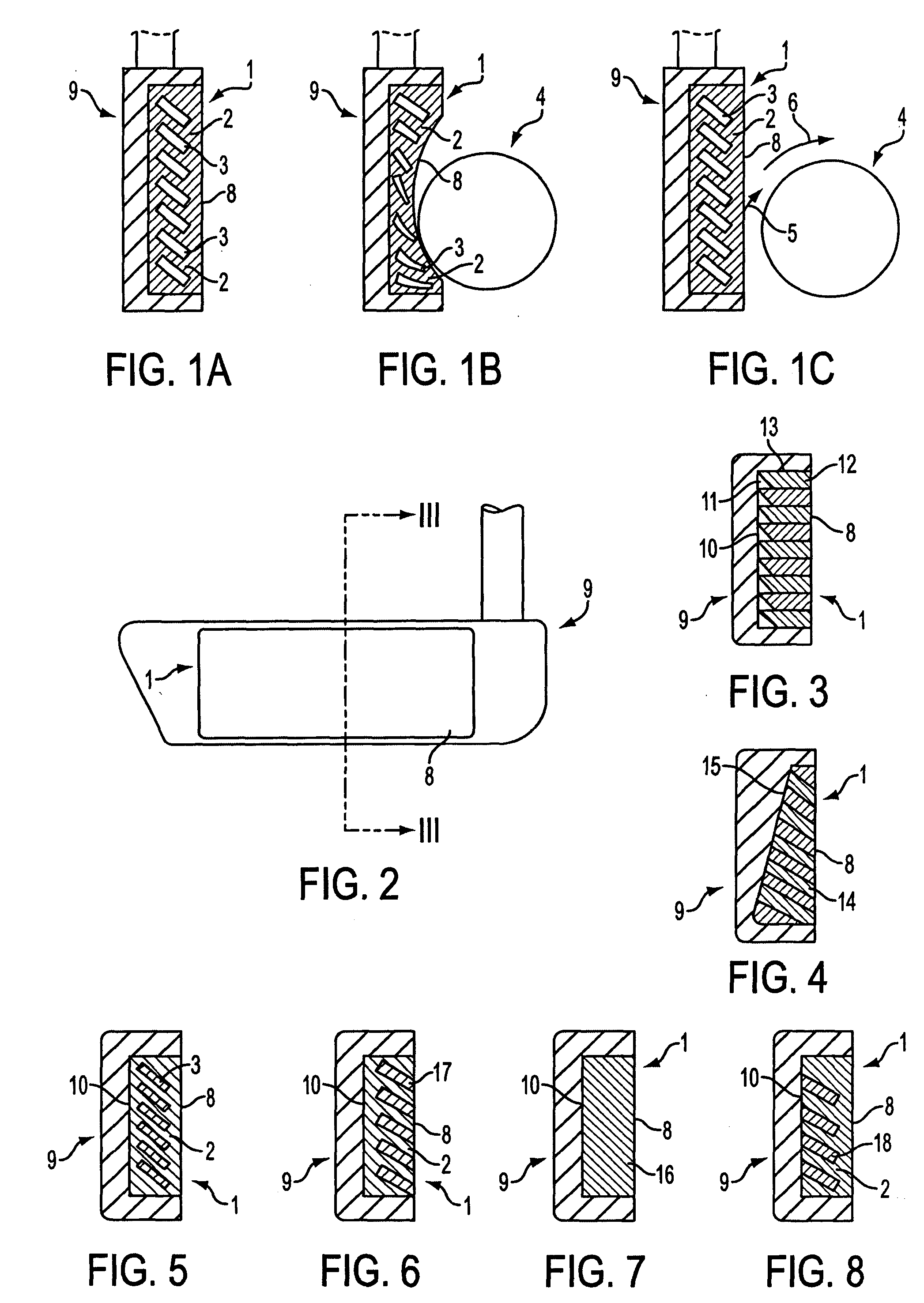

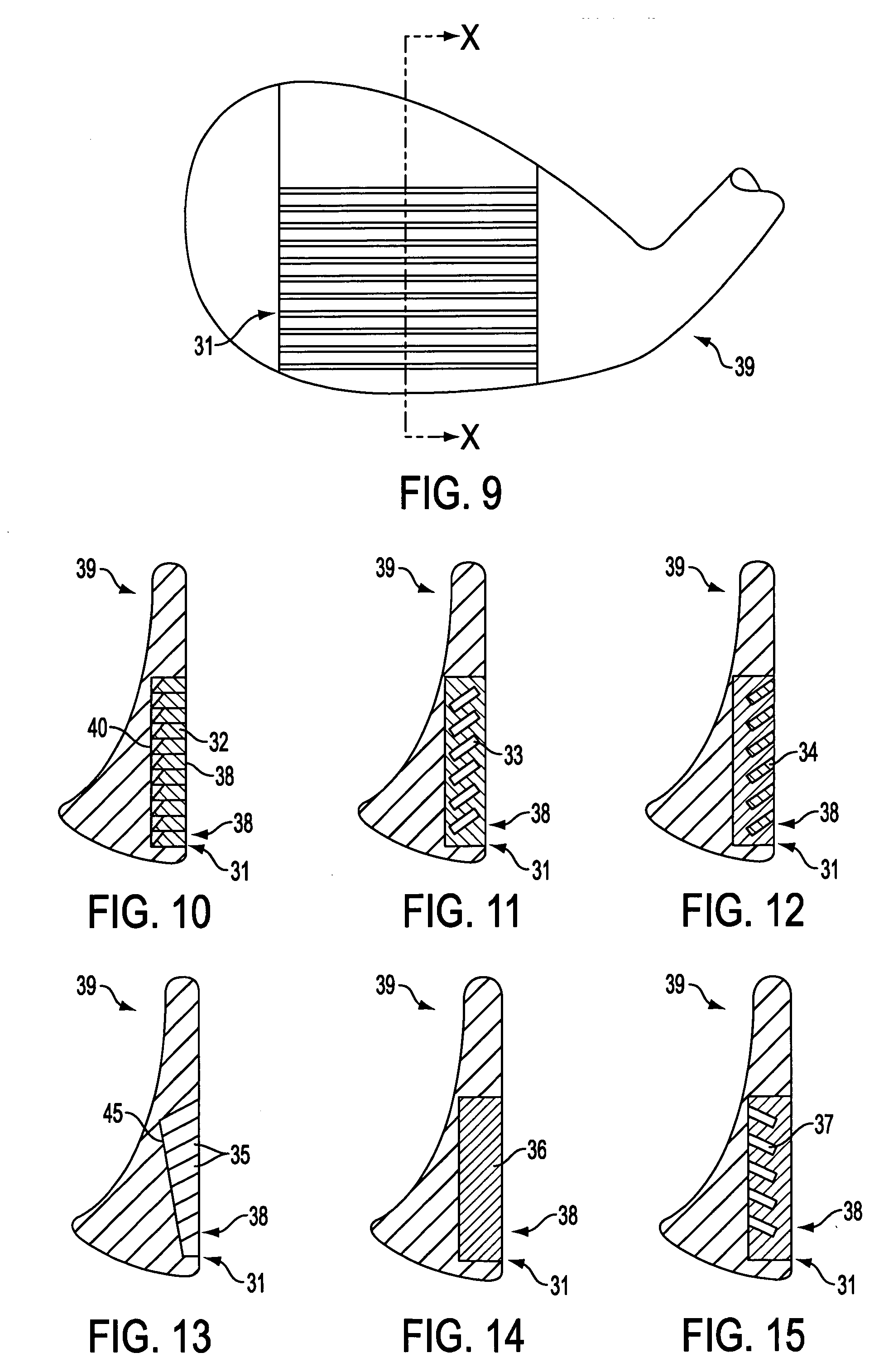

[0021] The invention provides an improved golf club head which allows the spin rate and direction of spin of the ball after impact with the club head to be controlled. Specifically, according to the invention, the volume behind the striking face comprises obliquely angled elements. These elements may be voids or objects of hardness greater or lesser than the remainder of the striking plate material. These elements may also be independent pixels with angled ends or laminations of varying hardness set at an angle to the front striking face. Upon impact with a golf ball, the compression and rebound of the impact face is influenced by the angled elements. The result is a striking face that can impart desired side, back, or top spin on the ball. The invention may be implemented in a golf club head insert wherein a golf club head is provided with a recess in the front striking face. A face plate insert is constructed according to the invention as described below and retained in the recess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com