Mounting bracket for an electrical box

a technology for mounting brackets and electrical boxes, which is applied in the direction of curtain suspension devices, filing appliances, coupling device connections, etc., can solve the problems of inability to guarantee, inconvenient installation, and inability to mount studs,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

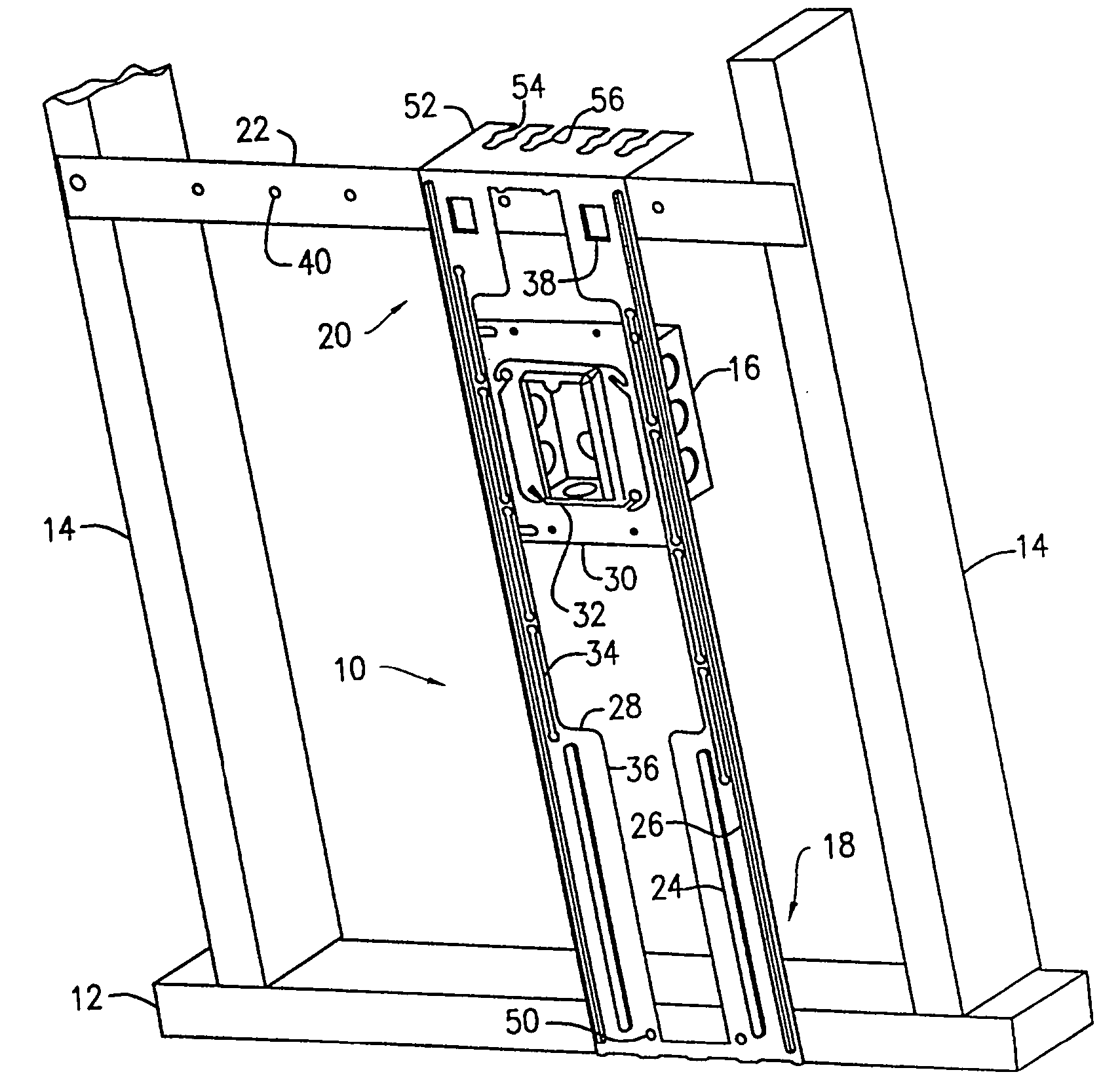

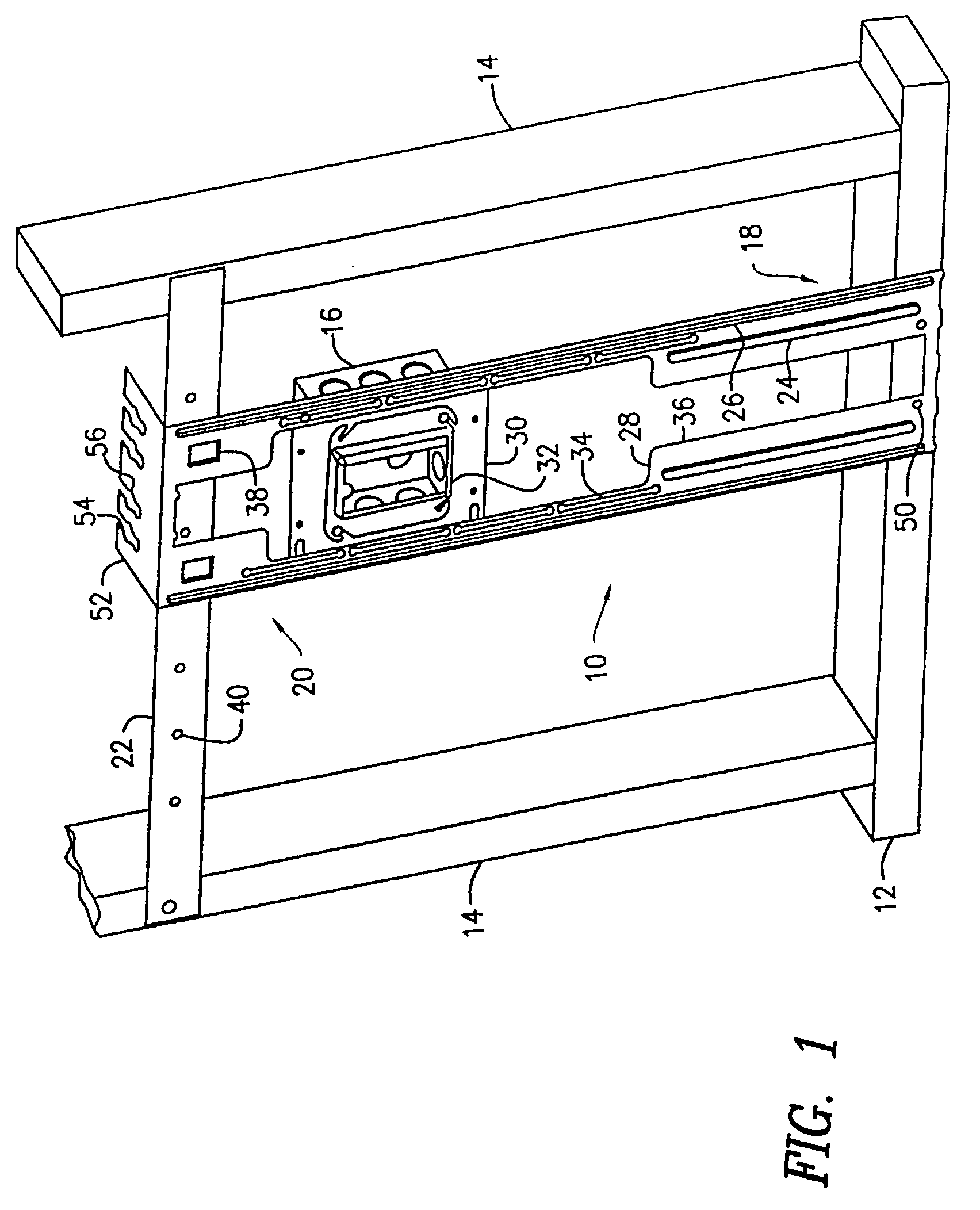

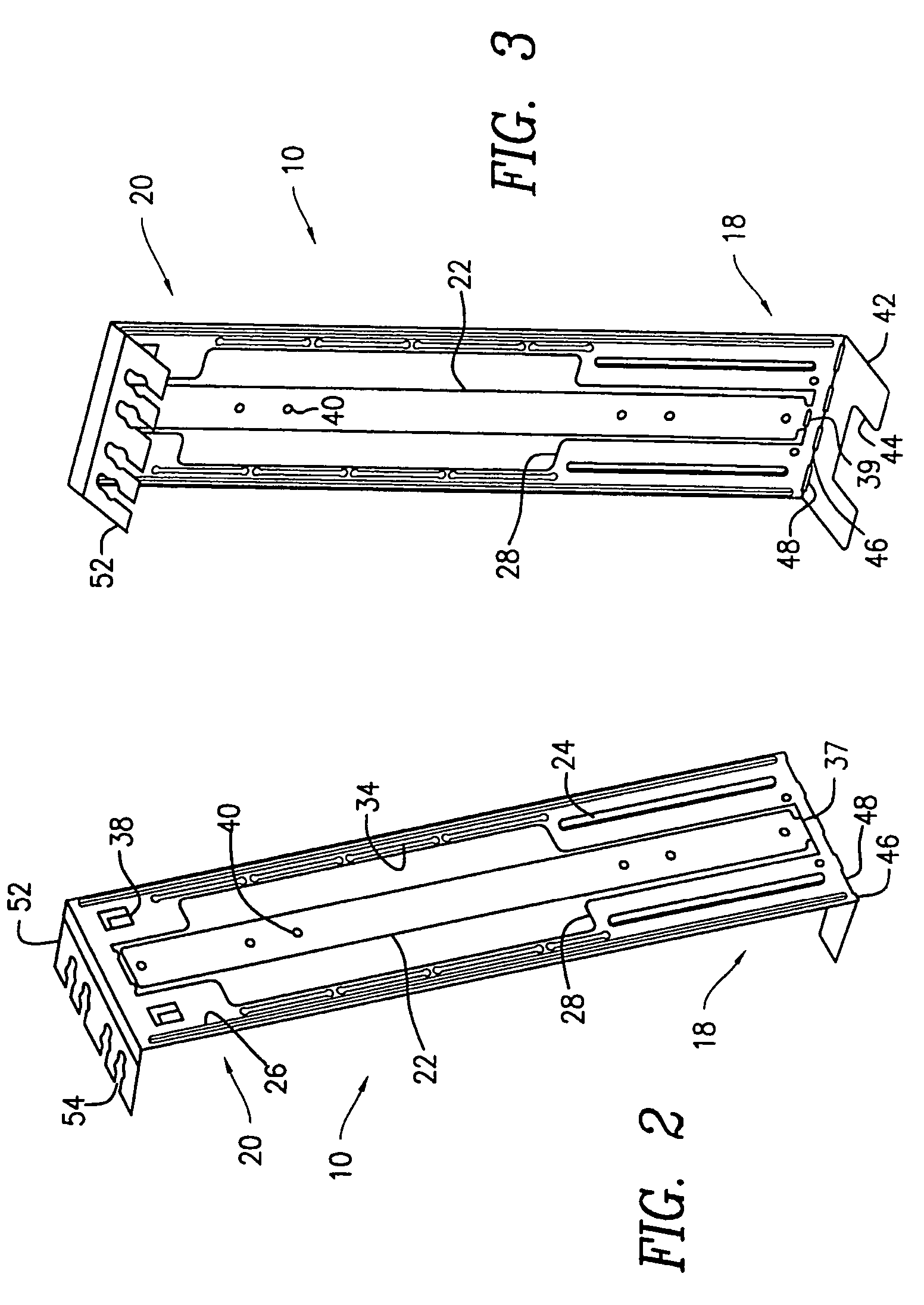

[0029] Referring initially to FIGS. 1-3, there is shown in this embodiment bracket 10 extending vertically from floor track 12 between two adjacent wall studs 14 of a building. Bracket 10 is elongated in shape and is shown as being constructed from thin metal material, but other materials are equally suitable and bracket 10 need not be unitary as illustrated. Bracket 10 is designed to mount an electrical box 16 a desired distance above the floor of the building within a wall cavity between adjacent studs 14, this box 16 abutting the back surface of bracket 10.

[0030] A lower portion 18 of bracket 10 can be directly mounted to floor track 12 such as via screws or nails. This lower portion can also be slightly offset for both better securement to the floor track and to inset the remainder of bracket 10 slightly into the wall structure in order to accommodate the thickness of any plaster ring or other plate that may be mounted to the front side of bracket 10.

[0031] Upper portion 20 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com