Submarine pipeline spoiler

a technology for submerged pipelines and spoilers, which is applied in the direction of valves, mechanical equipment, valve operation/release devices, etc., can solve the problems of long time for self-burying, and inability to bury pipelines at sea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

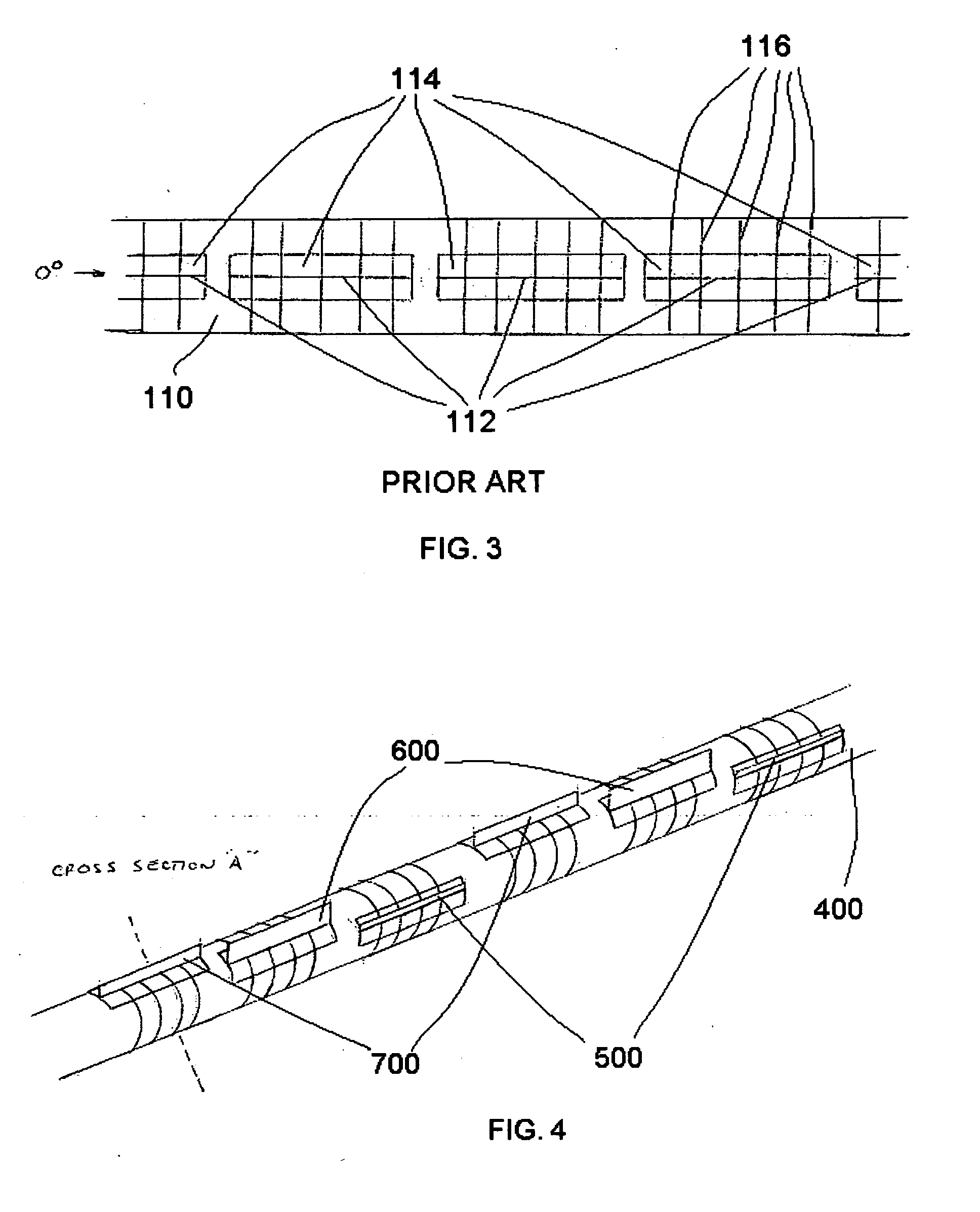

[0038] In a second embodiment, the present invention is incorporated by way of a new seat template as shown in FIG. 9. This new seat template has three grooves for receiving fins. In FIG. 9, the grooves are spaced radially by 20 degrees, but in practice may be spaced at other radial intervals as desired. It likewise is possible to provide two or more than three groove radially spaced on the seat. With a triple seat of the type shown in FIG. 9, one can achieve the alternating fin placement shown in FIG. 4 using the same triple seat design for each spoiler and placing the fins in the various grooves in the seat.

third embodiment

[0039] In a third embodiment, a piggy-back seat structure such as is shown in FIG. 10 may be incorporated into a triple seat such as is shown in FIG. 9 to provide for both piggy-backing of a pipe on top of the pipeline and for alternating fin placement as shown in FIG. 4. Such a triple piggy-back seat is shown in FIG. 11. The triple piggy-back seat has three grooves 214 for receiving fins 300, with the grooves being spaced radially by 20 degrees. The seat further has inner side members 216 forming a concave portion for receiving the piggy-back pipe 222, outer side members 220, and support members 218. The grooves, of course, may be spaced radially at angles different than 20 degrees. Likewise, more grooves could be used if such was desirable for particular environmental conditions. Further, other structures of support members, outer sides, and inner sides may be used.

[0040]FIG. 12 is a graph of the hydrodynamic coefficients as a function of spoiler height. This graph generally shows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com