Anti-sweat heater control system and method

a control system and heater technology, applied in the direction of defrosting, cooling fluid circulation, domestic applications, etc., can solve the problems of large amount of “anti-sweat” required, the heat put into the frame is roughly half of the heat, and the electricity cost is significant, so as to achieve the effect of reducing condensation and/or eliminating condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

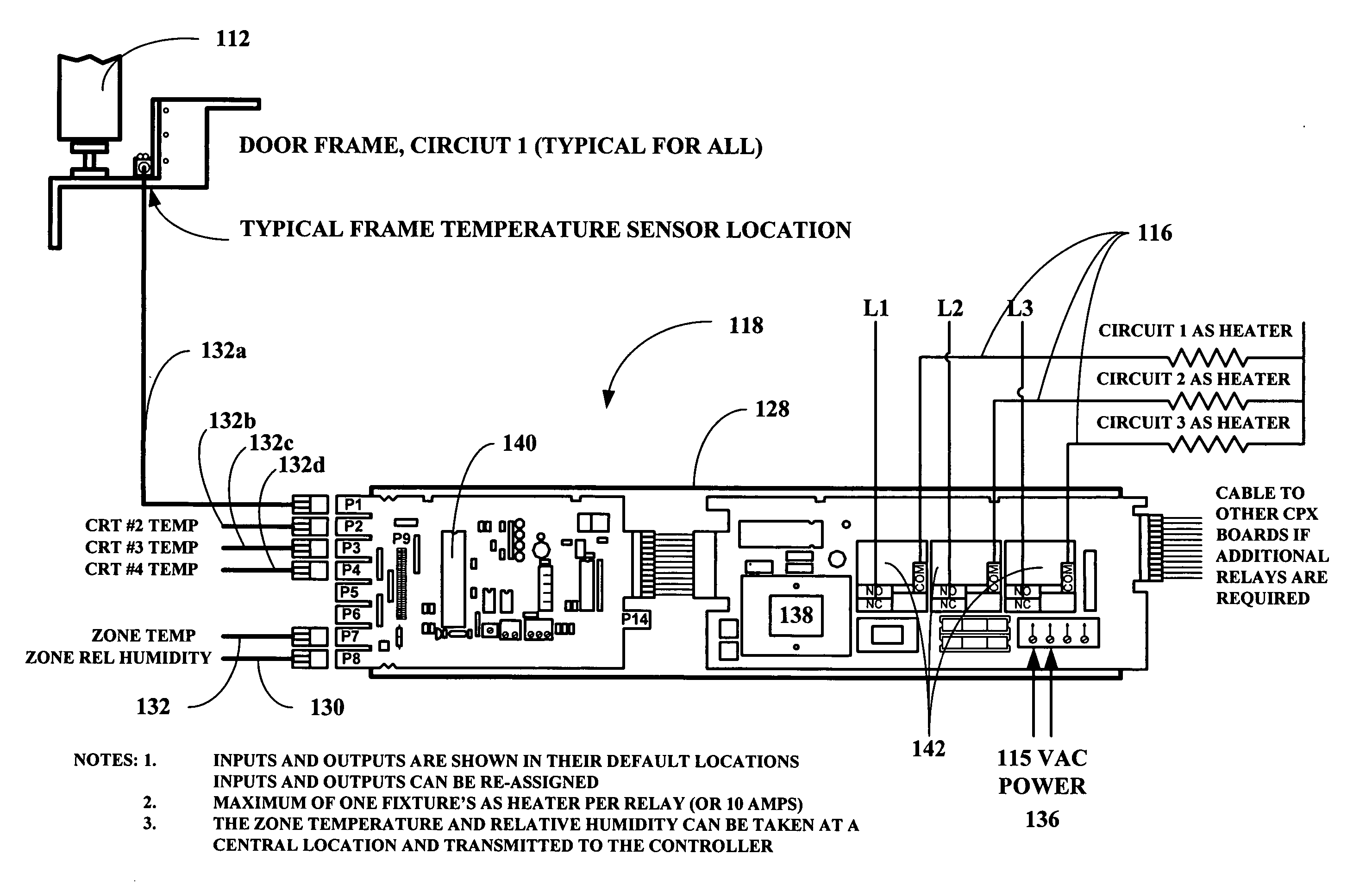

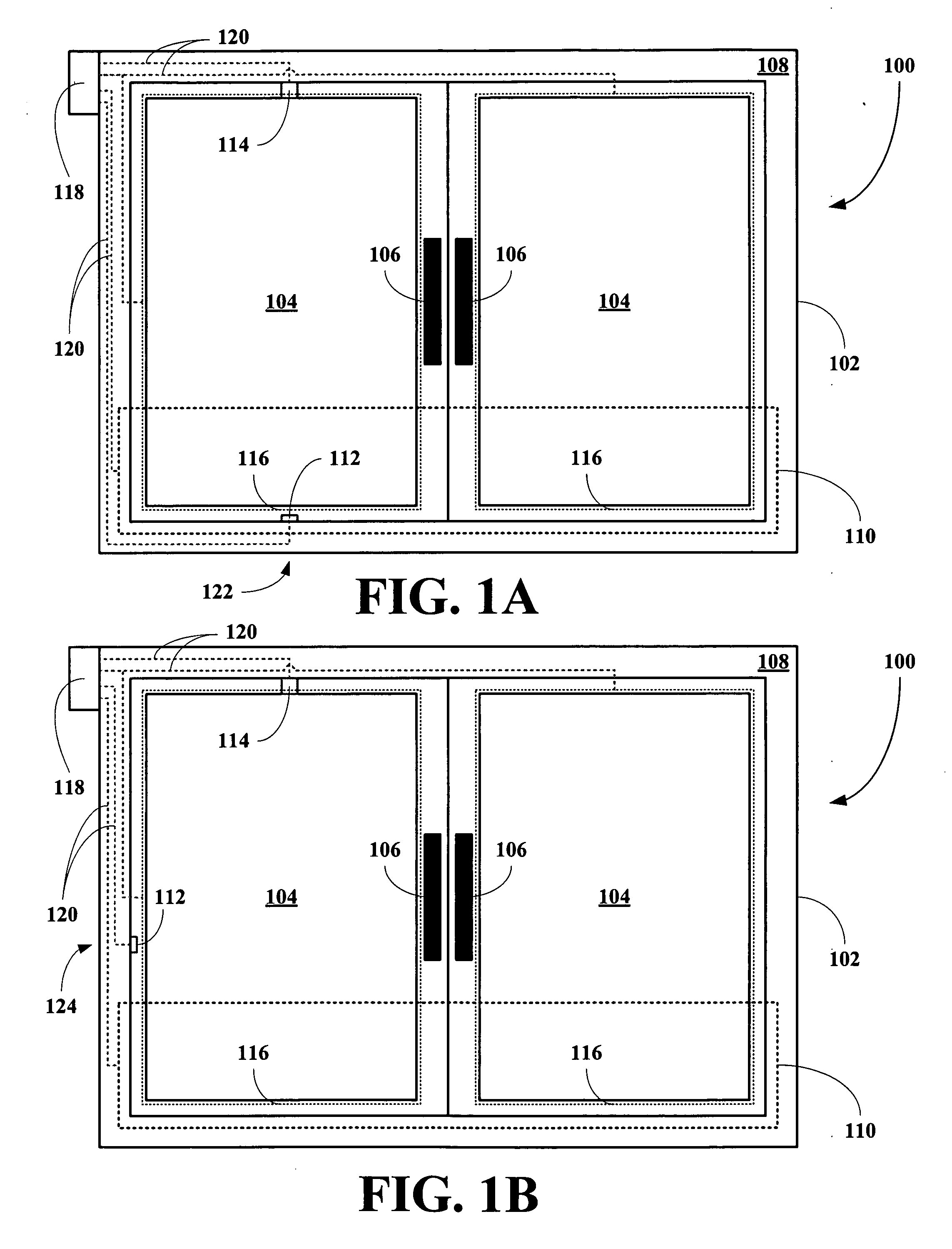

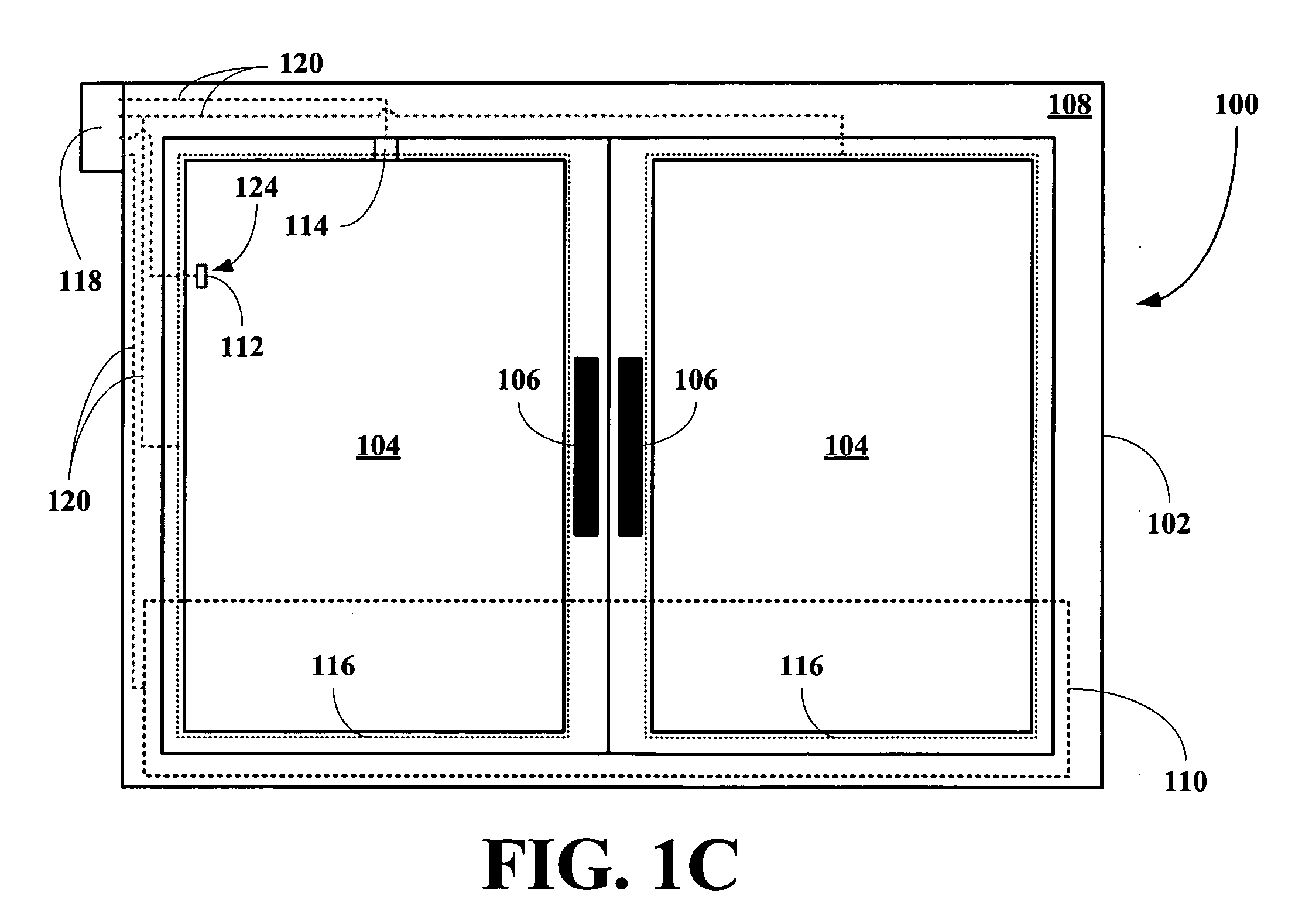

[0018] The inventors have found that an anti-sweat heater control system can be incorporated into a refrigeration circuit of a refrigerated container or plurality of refrigerated containers, where the control system includes a plurality of heaters, one for each door frame or outer surface for which anti-sweat protection is desired, a temperature sensor located at a location on or associated with at least one door frame or outer surface of the refrigerated container and a zone relative humidity sensor, where the heaters are turned on whenever the temperature sensor reading is below a diversity factor corrected set point temperature and where the diversity factor is a difference between the temperature sensor reading and a critical temperature. The benefits of using a “diversity” factor verses a fixed set point are that: (1) the temperature sensor can be located where it is convenient rather than having to locate the sensor at the critical location, which may not be in a particularly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com