Elastomeric nonwoven laminates and process for producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The method, material, and the apparatus of the present invention are designed to provide a more cost effective and / or consumer desirable elastomeric laminate suitable for use in a variety of articles including disposable absorbent articles.

Definitions

[0033] The following terminology is used herein consistent with the plain meaning of the terms with further details provided in the present specification.

[0034] The terms “activating”, “activation” or “mechanical activation” refer to the process of making a substrate, or an elastomeric laminate more extensible than the it was prior to the process.

[0035]“Basis weight” refers to the weight of a planar material for a given surface area. Basis weight is typically measured in grams per square meter (gsm). The basis weight of an elastomeric laminate is typically measured in an unstrained configuration.

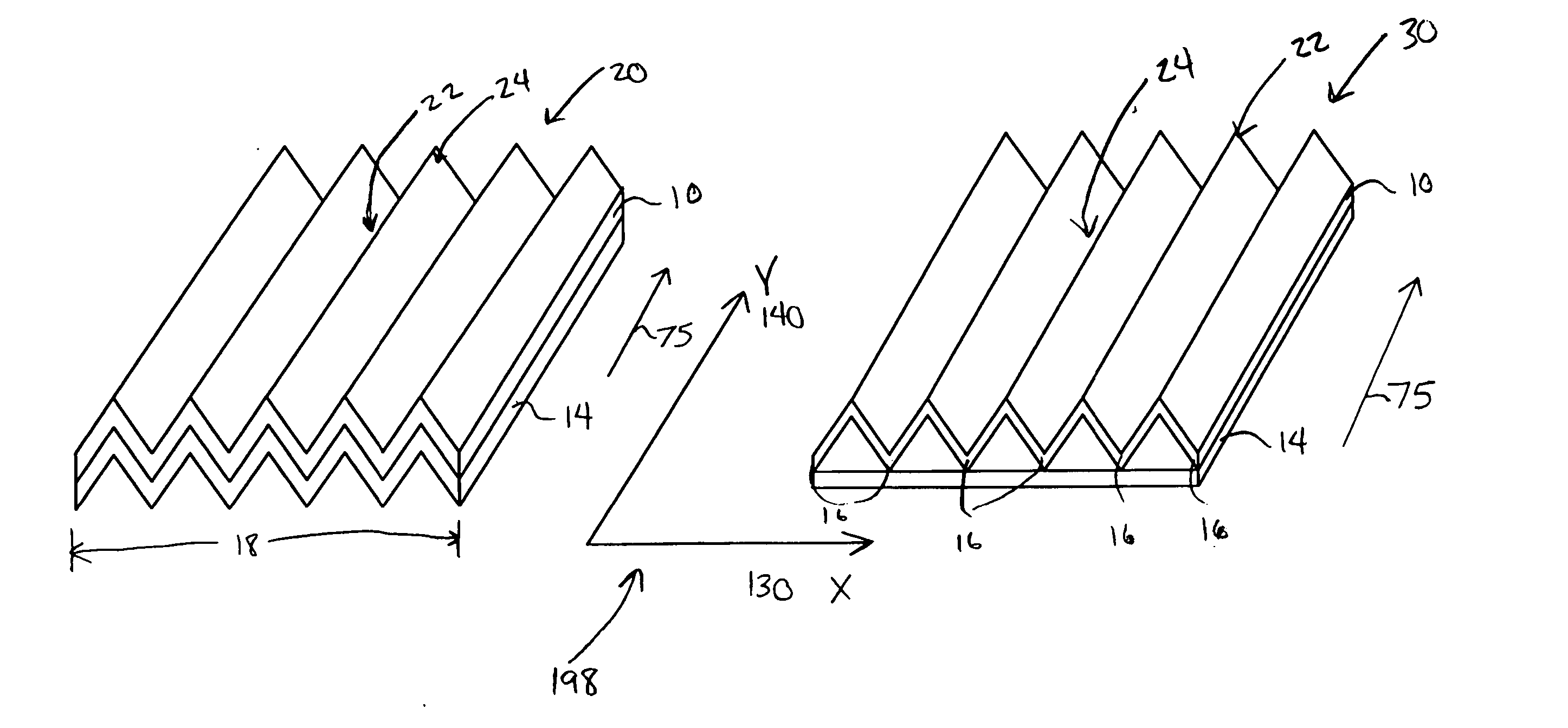

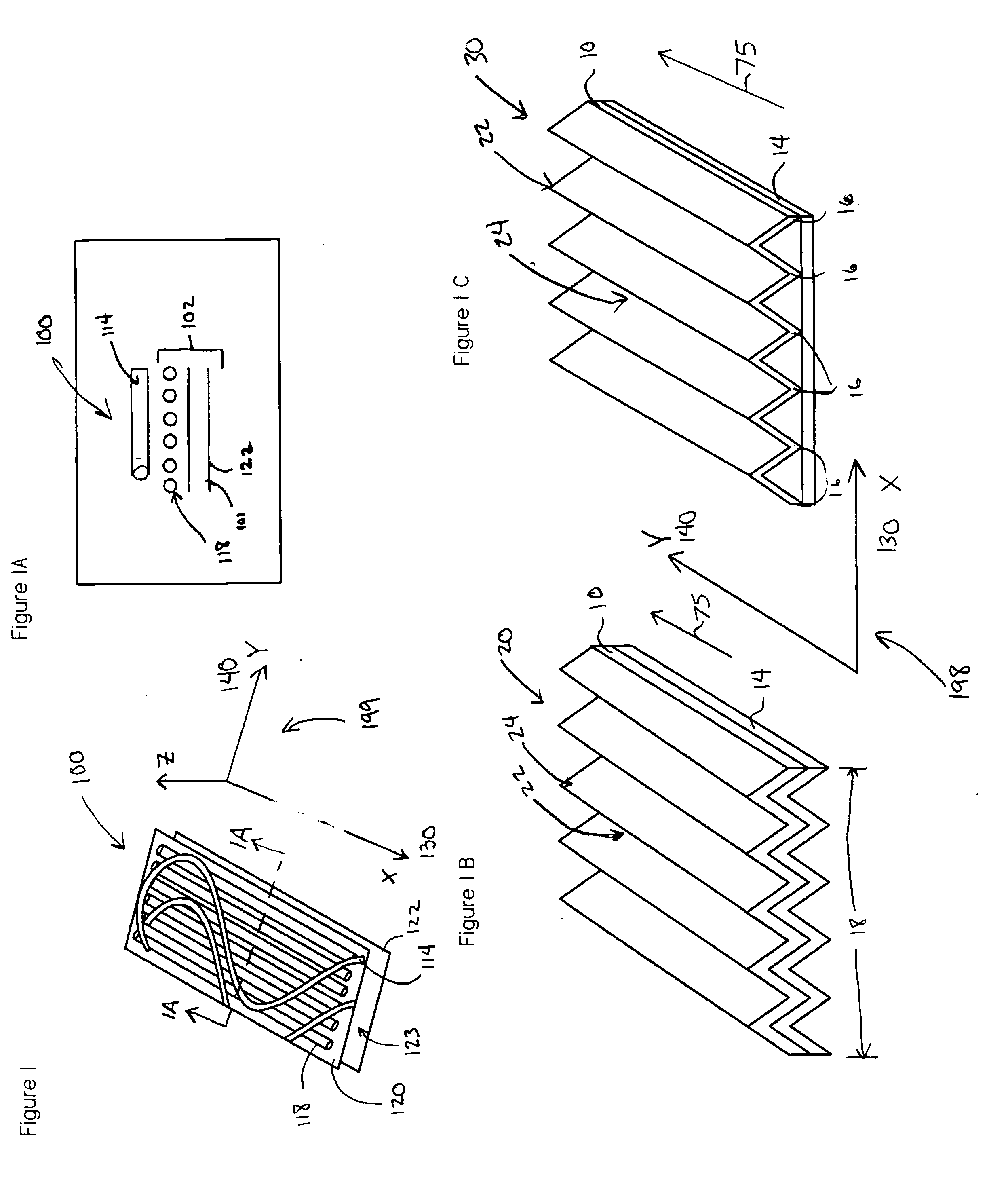

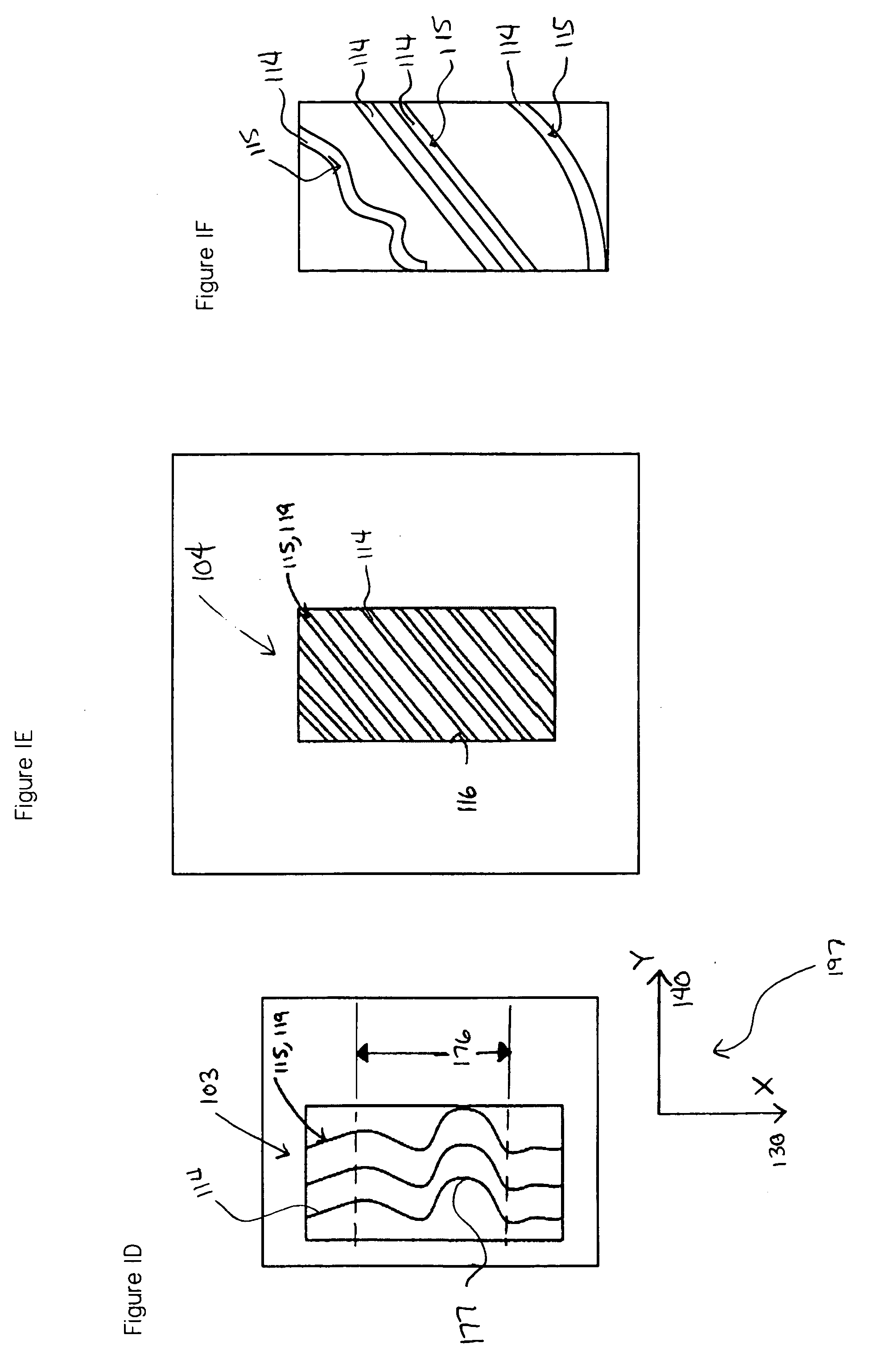

[0036] The terms “corrugations” or “ruggosities” are used to describe hills and valleys that occur in a substrate or in a laminate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Elastomeric | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com