Container having label protection feature

a label protection and container technology, applied in the field of blow molding plastic containers, can solve the problems of excessively increasing the cost of the product, so as to improve the visual continuity of the container profile and promote the effect of positive impa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description of the preferred embodiment is merely exemplary in nature and is in no way intended to limit the invention, its applications or uses.

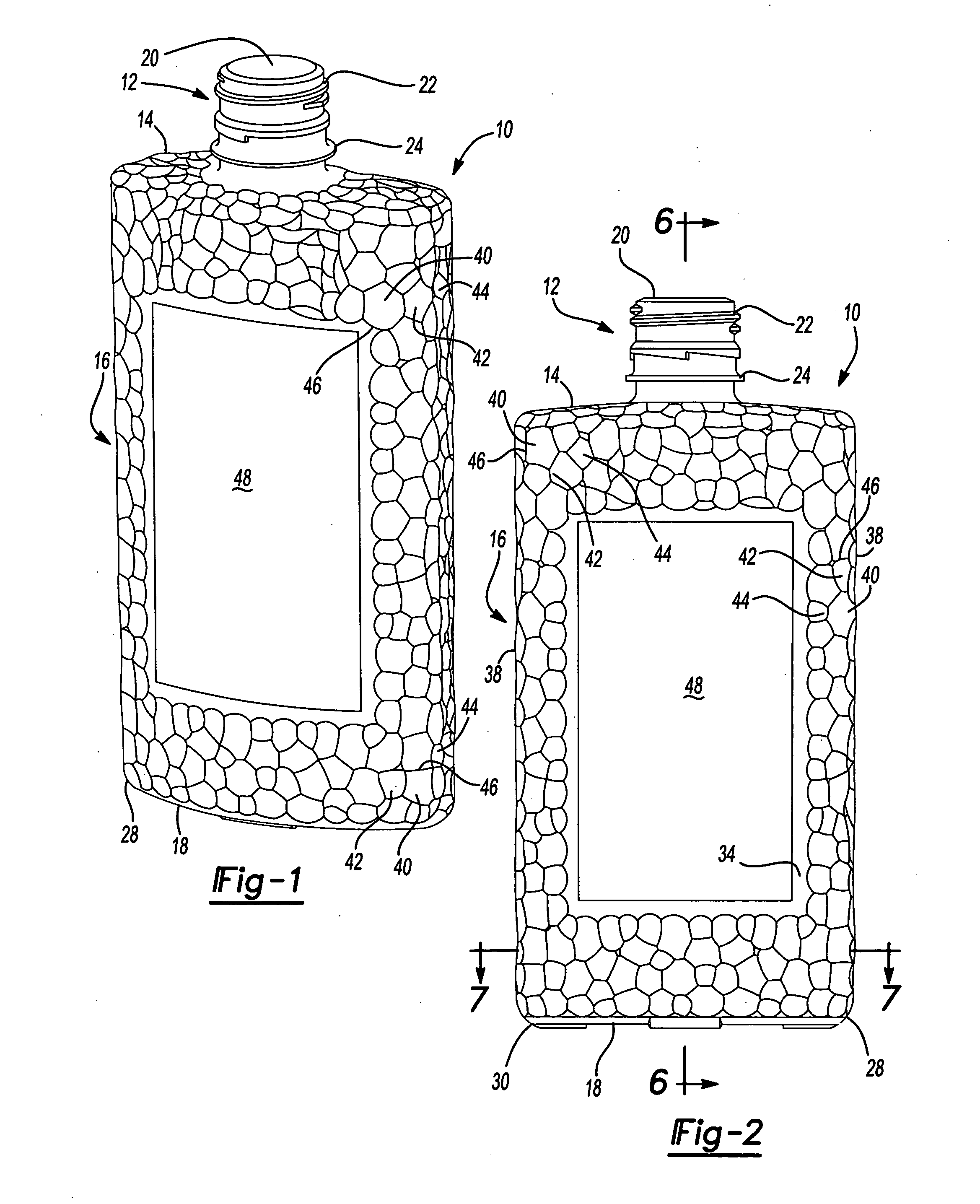

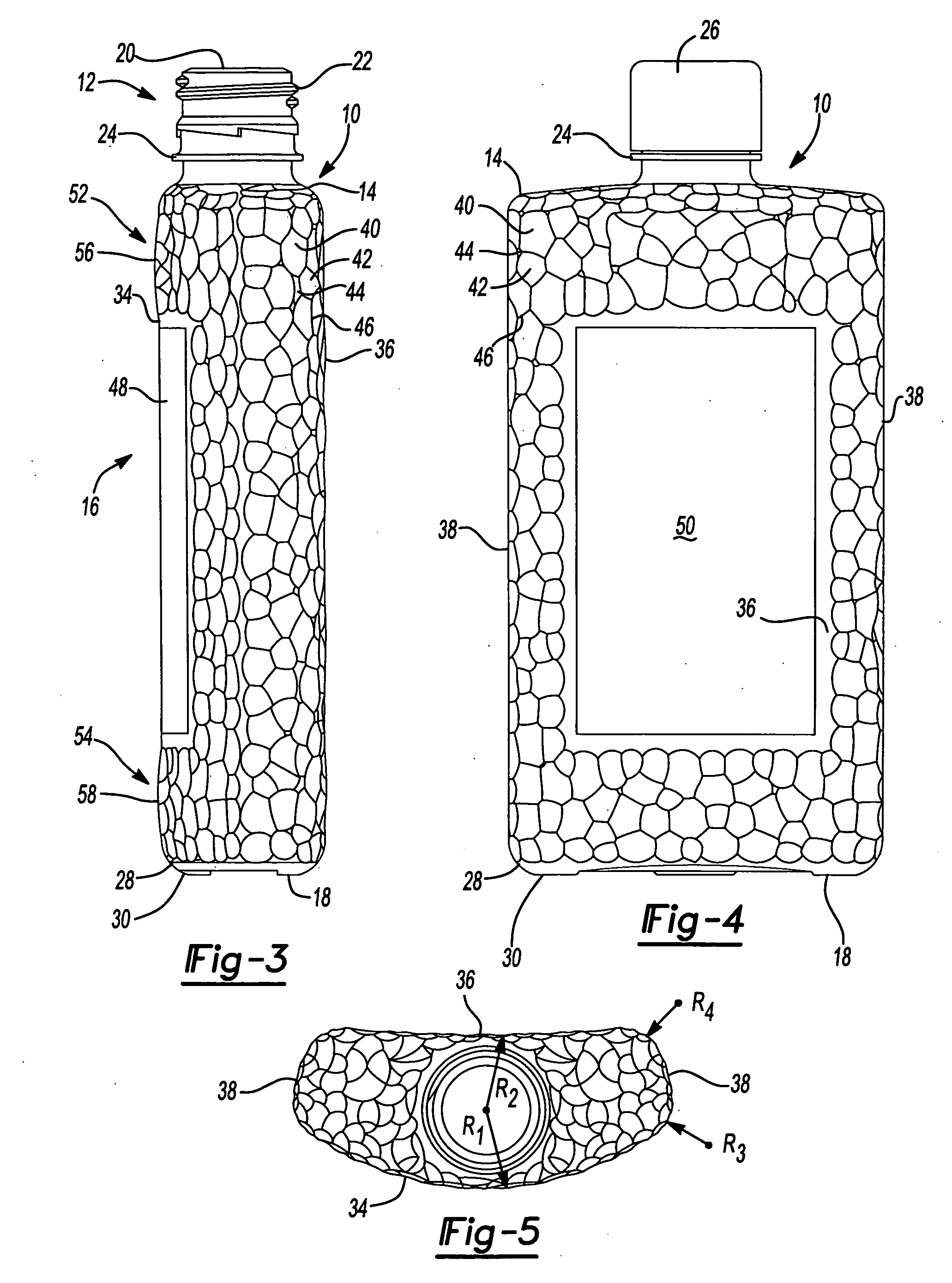

[0026] As discussed above, to promote product label area protection, containers have been provided with ledges above and below the product label area. Traditionally, these ledges add structure, weight and thus costs from a material standpoint to the sidewall of the container, and create stress points which weaken the sidewall. These ledges further interrupt the visual continuity of the container profile, lessening the positive impact generated by the container product label.

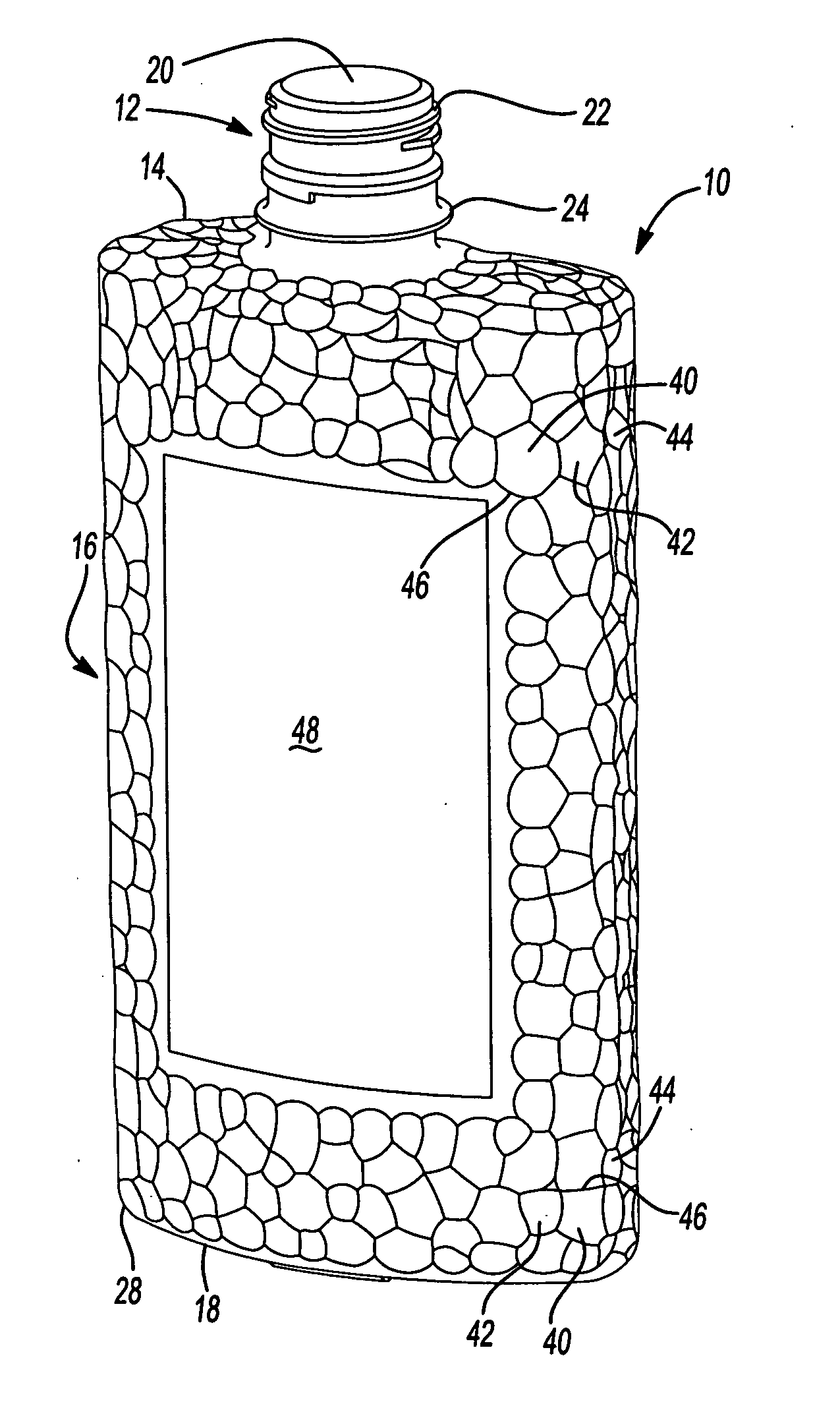

[0027] Referring now to the drawings, there is depicted a blow molded plastic container 10 embodying the principles and concepts of the present invention. The container 10 of the present invention illustrated in FIGS. 1-8 is particularly suited for packaging of product, typically a liquid or beverage. The container 10 can be filled by automated, hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com