Constant-temperature fluid supply system

a fluid supply system and constant temperature technology, applied in the direction of refrigeration machines, machines using electric/magnetic effects, domestic cooling apparatus, etc., can solve the problems of inability to control the temperature of water, the inability to control the accuracy of target devices, and the inability to achieve high degree of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

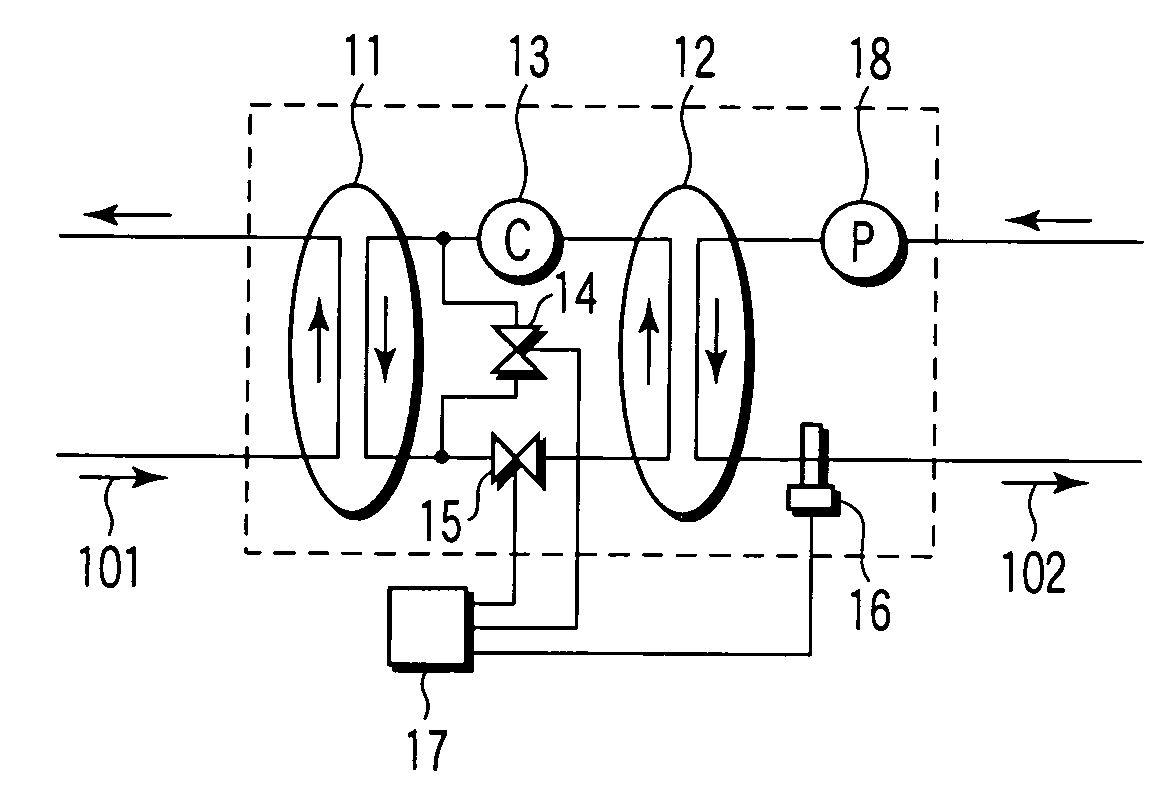

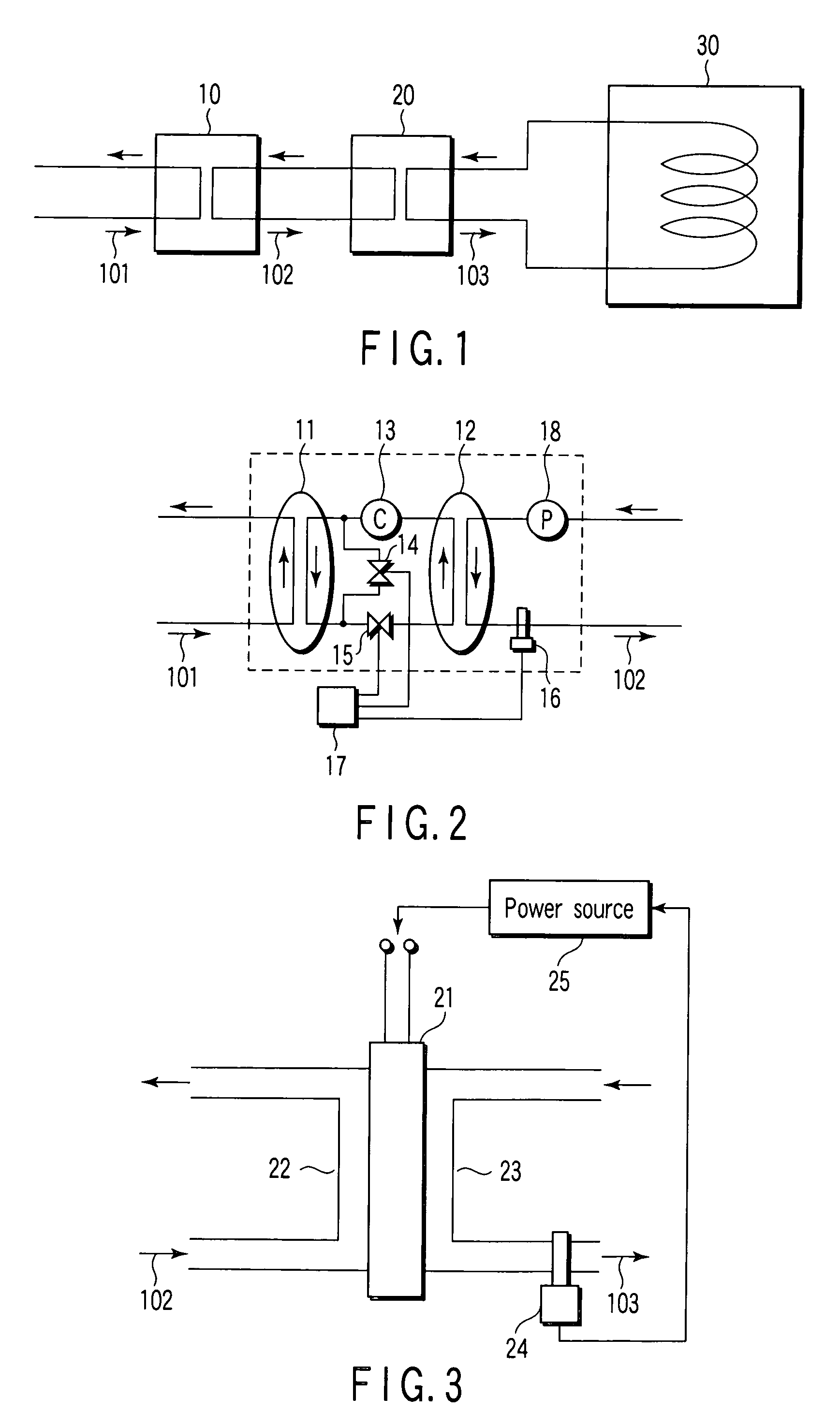

[0030] In FIG. 1, reference numeral 10 denotes a first constant-temperature fluid supply apparatus. Cooling water 101 (i.e., cooling fluid), which is tap water or circulation water in plants, is supplied to the input side of the apparatus 10. First constant-temperature water 102 (i.e., a first constant-temperature fluid) is output from the output side of the apparatus 10. Reference numeral 20 denotes a second constant-temperature fluid supply apparatus. First constant-temperature water 102 is supplied to the input side of the apparatus 20 as cooling water. Second constant-temperature water 103 (i.e., a second constant-temperature fluid) is output from the output side of the apparatus 20. The second constant-temperature water 103 is supplied to an external apparatus 30 (i.e., an apparatus whose temperature is to be kept constant), for maintaining its constant temperature.

[0031] The first and second constant-temperature fluid supply apparatuses 10 and 20 are connected together by mea...

second embodiment

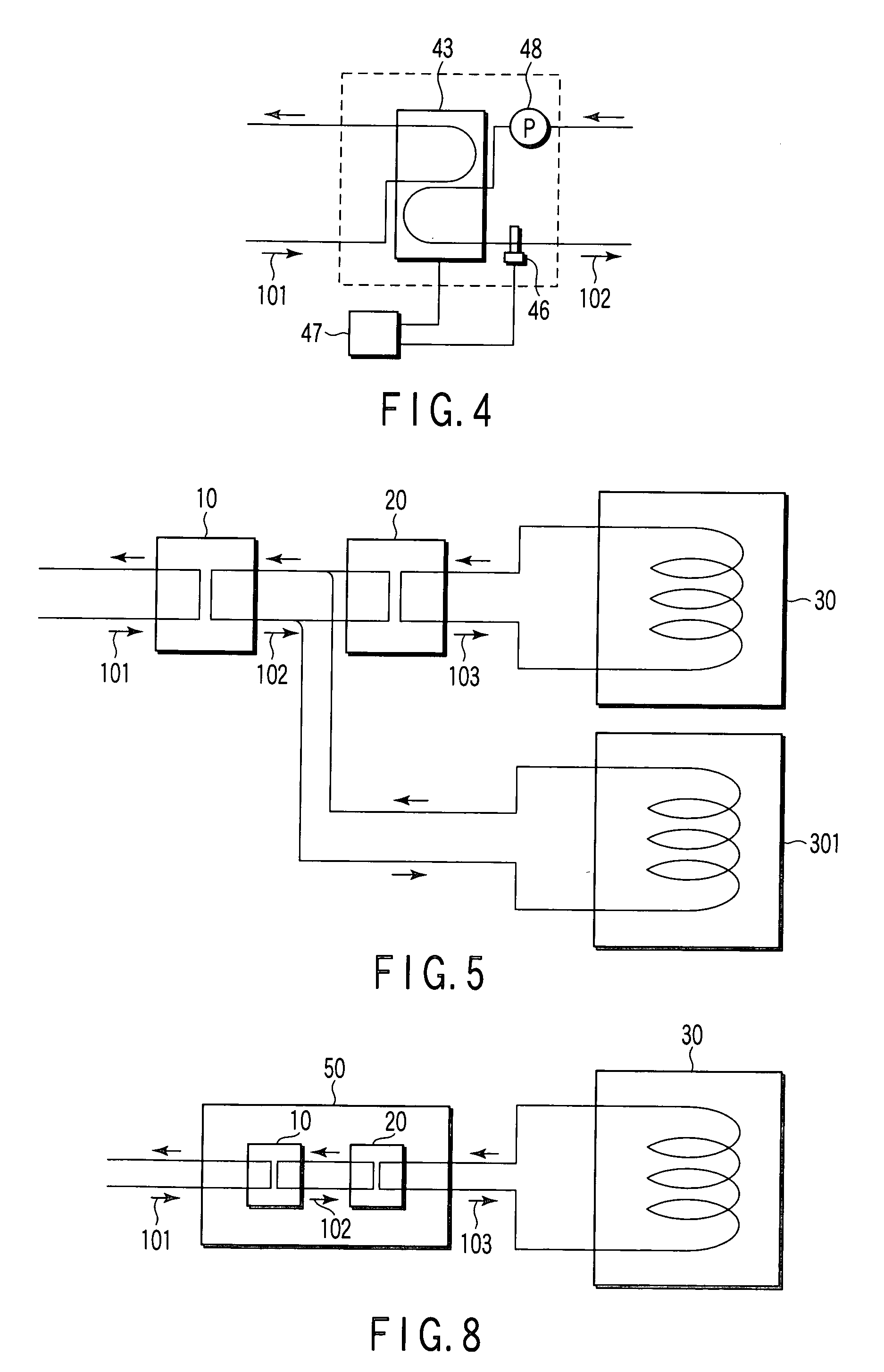

[0043]FIG. 5 is a schematic diagram showing a constant-temperature fluid supply system according to the second embodiment. In FIG. 5, similar or corresponding structural elements are denoted by the same reference numerals as used in FIG. 1, and a detailed description of such structural elements will be omitted herein.

[0044] The second embodiment differs from the first embodiment in that the first constant-temperature water 102 from the first constant-temperature fluid supply apparatus 10 is supplied to not only to the second constant-temperature fluid supply apparatus 20 but also to an external apparatus 301. In other words, part of the first constant-temperature water 102 is circulated between the first fluid supply apparatus 10 and the external apparatus 301. With this structure, the temperature of external apparatus 301 can be kept at a constant value to a certain extent (the temperature of external apparatus 301 cannot be so accurately controlled as the temperature of external ...

third embodiment

[0046]FIG. 6 is a schematic diagram showing a constant-temperature fluid supply system according to the third embodiment. In FIG. 6, similar or corresponding structural elements are denoted by the same reference numerals as used in FIG. 1, and a detailed description of such structural elements will be omitted herein.

[0047] The third embodiment differs from the first embodiment in that second constant-temperature fluid supply apparatuses 201 and 202 are provided in addition to the second constant-temperature fluid supply apparatus 20. In other words, three second constant-temperature fluid supply apparatuses 20, 201 and 202 are employed to keep the temperatures of external apparatuses 30, 301 and 302 at constant values.

[0048] In the third embodiment, the first constant-temperature water 102 is supplied to three apparatuses, namely constant-temperature fluid supply apparatus 20, constant-temperature fluid supply apparatus 201 and constant-temperature fluid supply apparatus 202. As i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com