Extraction device and wear ring for a rotatable tool

a technology of extraction device and rotatable tool, which is applied in the direction of cutting machines, slitting machines, earth drilling and mining, etc., can solve the problems of not being able to have a wear ring, and the forward surface of the tool holder to become worn away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

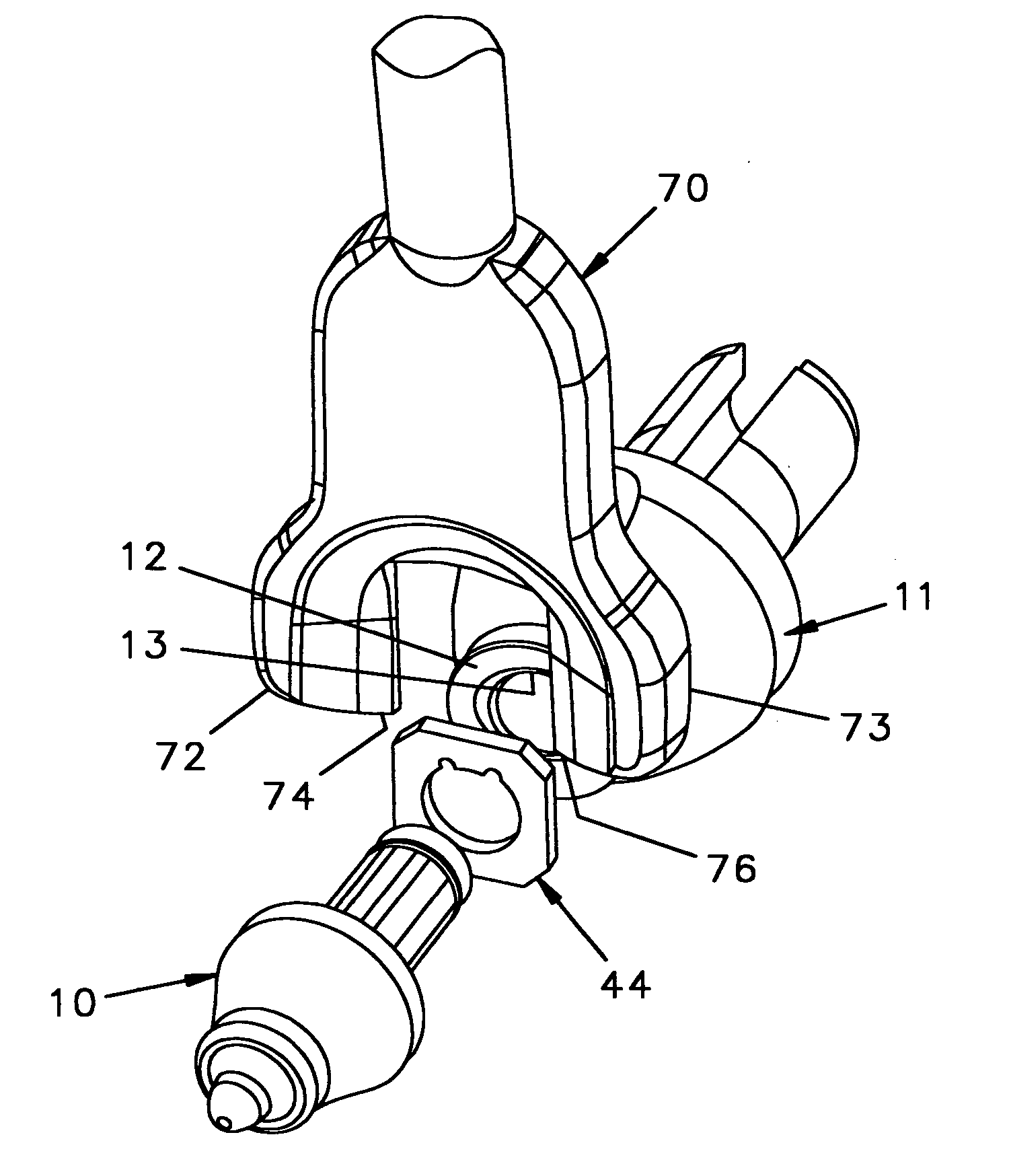

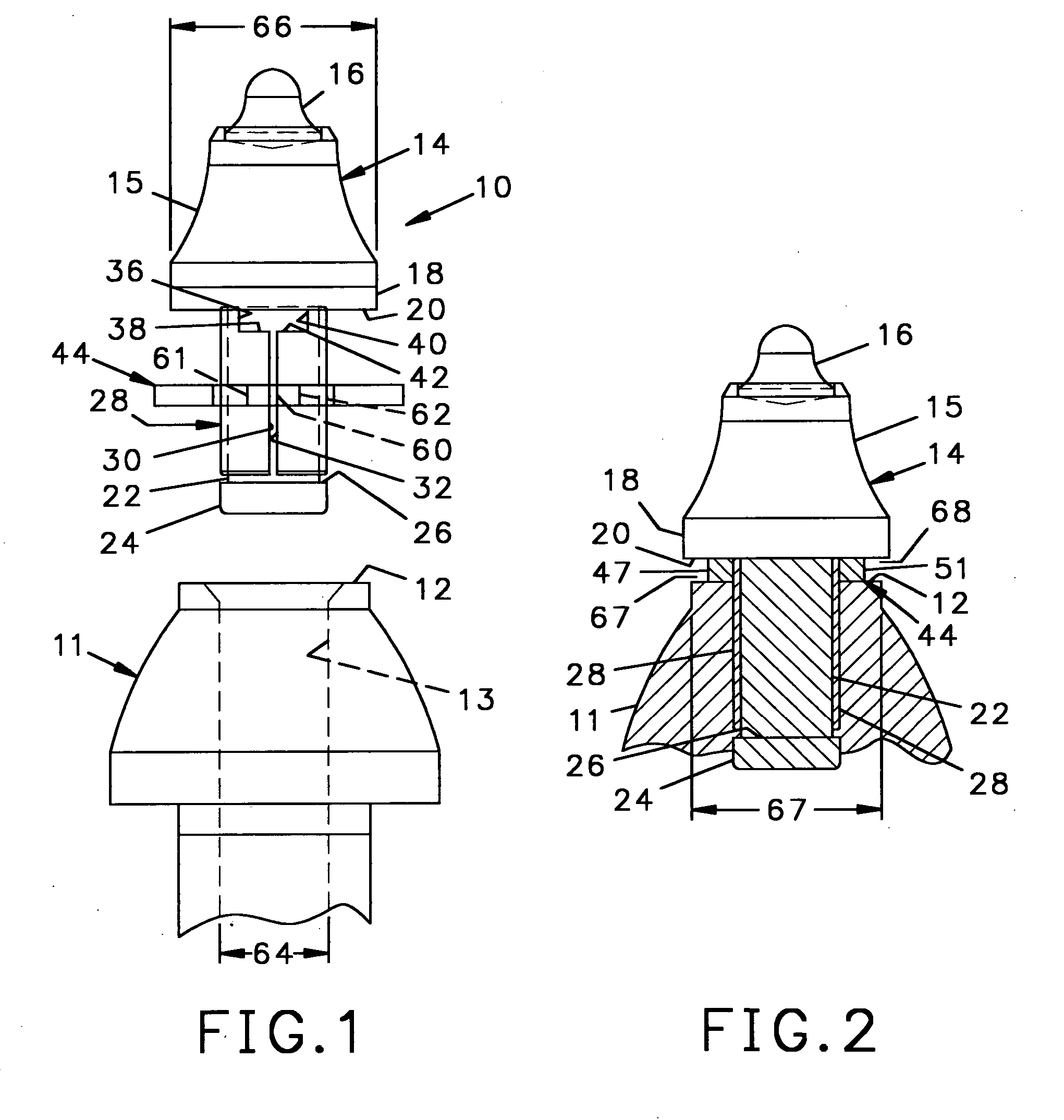

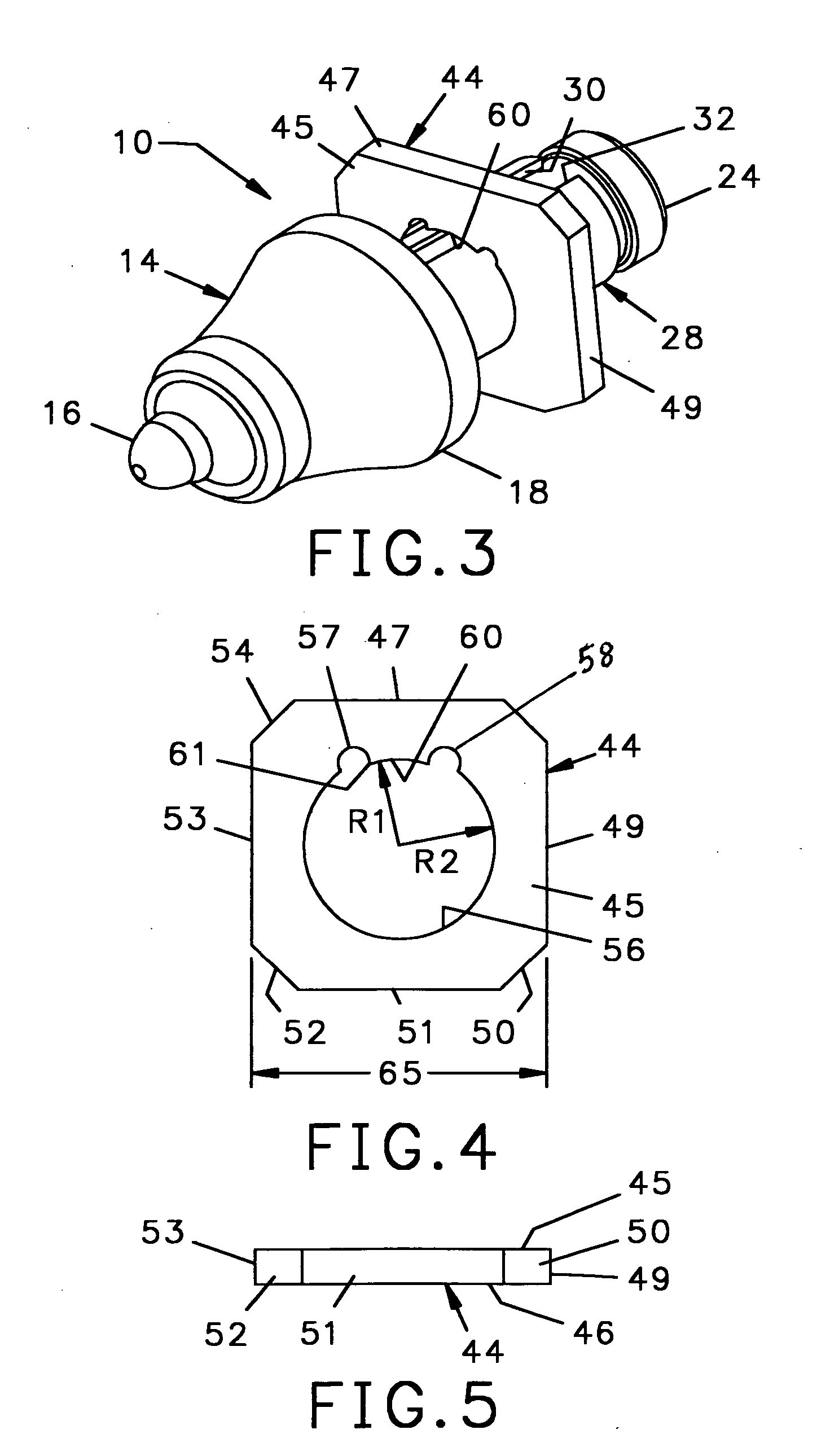

[0022] Referring to FIGS. 1 and 2, a tool 10 is suitable for being rotatably mounted in a tool holder 11 having a planar forward surface 12 and a bore 13, the axis of which is perpendicular to the forward surface 12. The tool holder 11 may be mounted directly to the drum or wheel of the machine or may be a quick-change holder as depicted. The tool 10 includes a tool body 14 having a tapered forward cutting portion 15 at the forward end of which is a seat into which is brazed a hardened cutting tip 16. The cutting portion 15 flares outwardly near its rearward end to a flange 18 having a generally planar annular rearward surface 20. Extending axially rearwardly from the center of the annular rearward surface 20 is a cylindrical shank 22 having an enlarged hub 24 at the distal end thereof. The hub 24 forms a shoulder 26, and fitted forwardly of the shoulder 26 is a compressible sleeve 28 made of a suitable spring steel.

[0023] The compressible sleeve 28 generally defines a hollow cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com