Gutter debris screen

a technology of debris screen and gutter, which is applied in the direction of roof covering, roof, construction, etc., can solve the problems of slipping through the gutter, affecting the appearance of the gutter,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

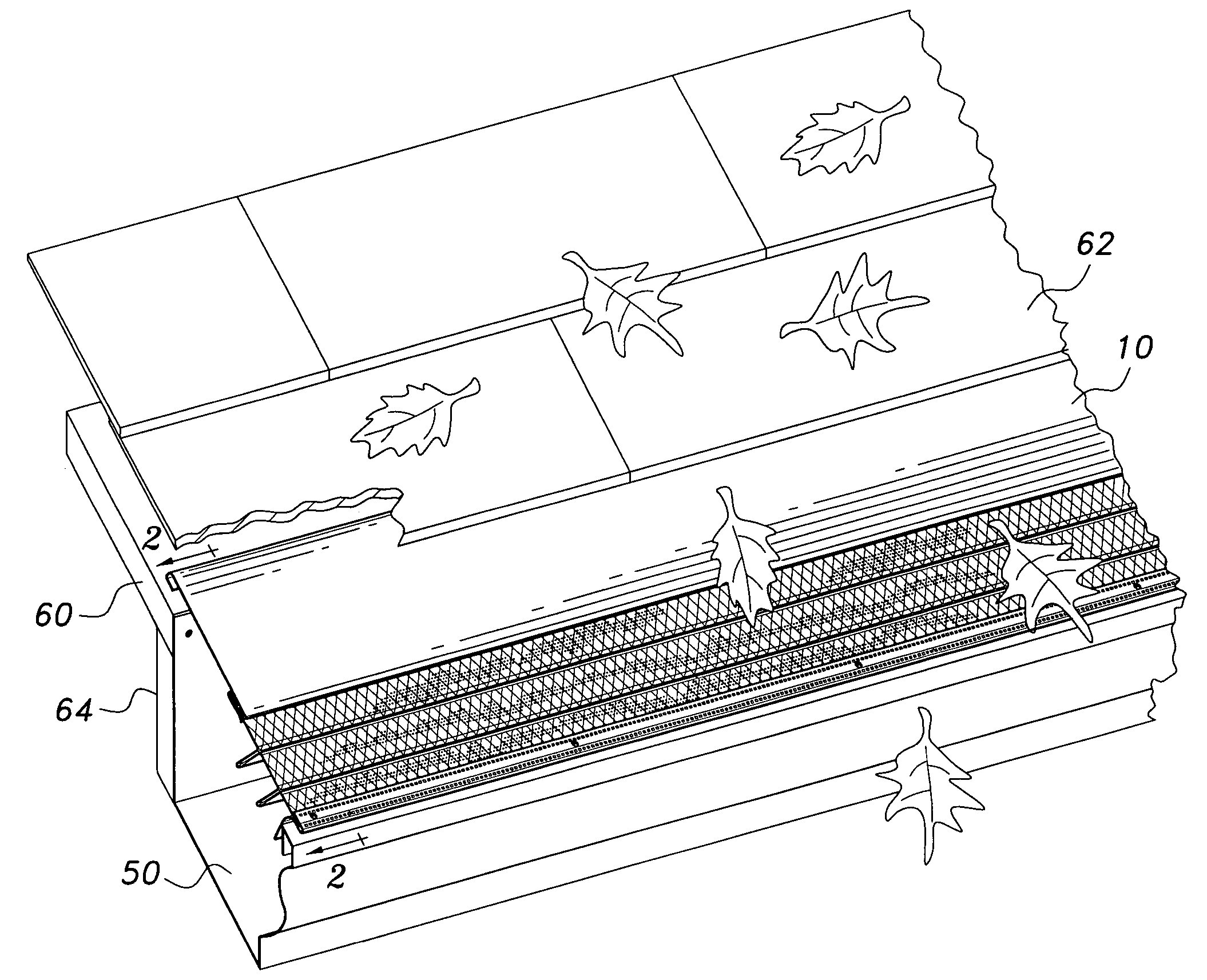

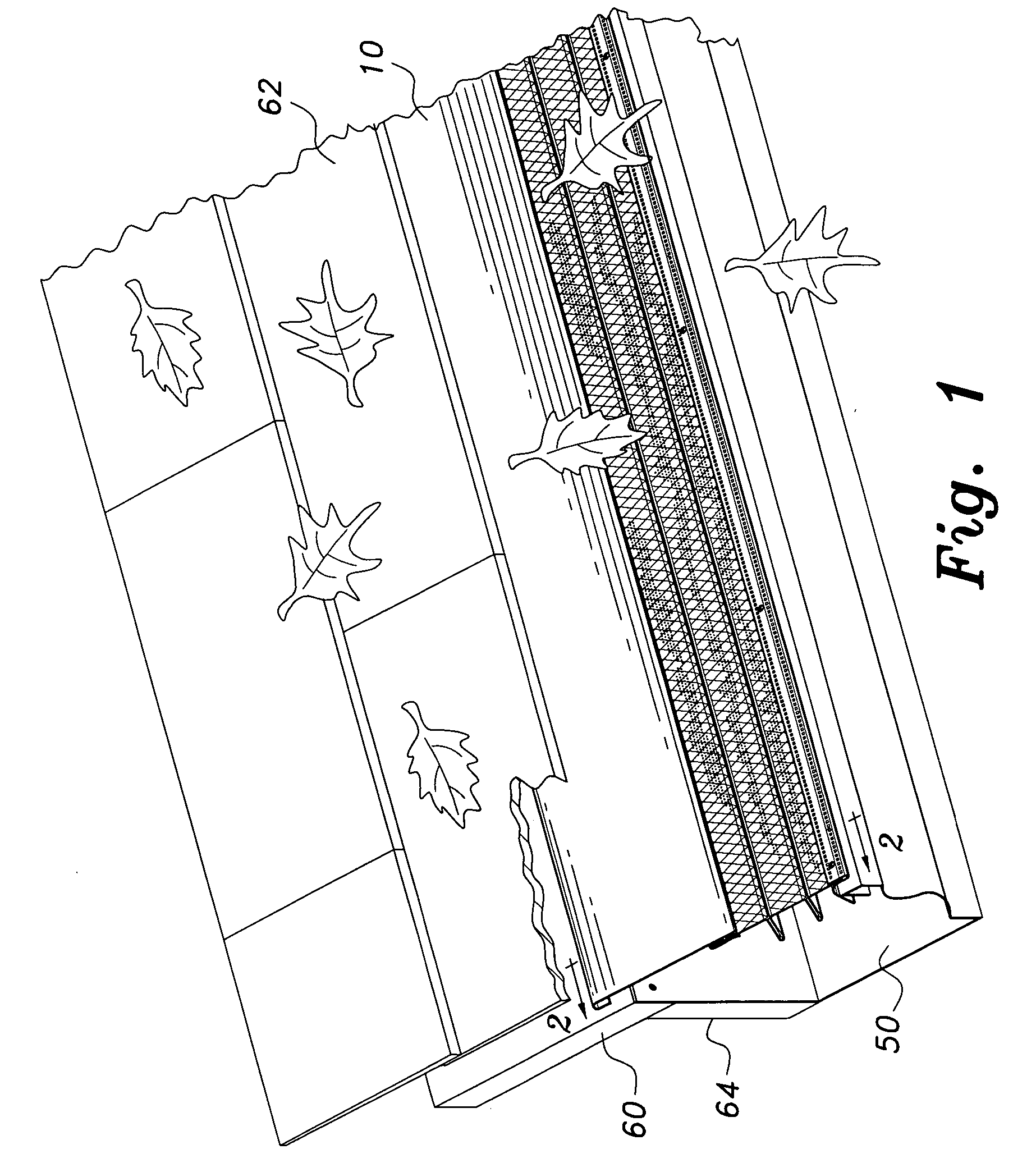

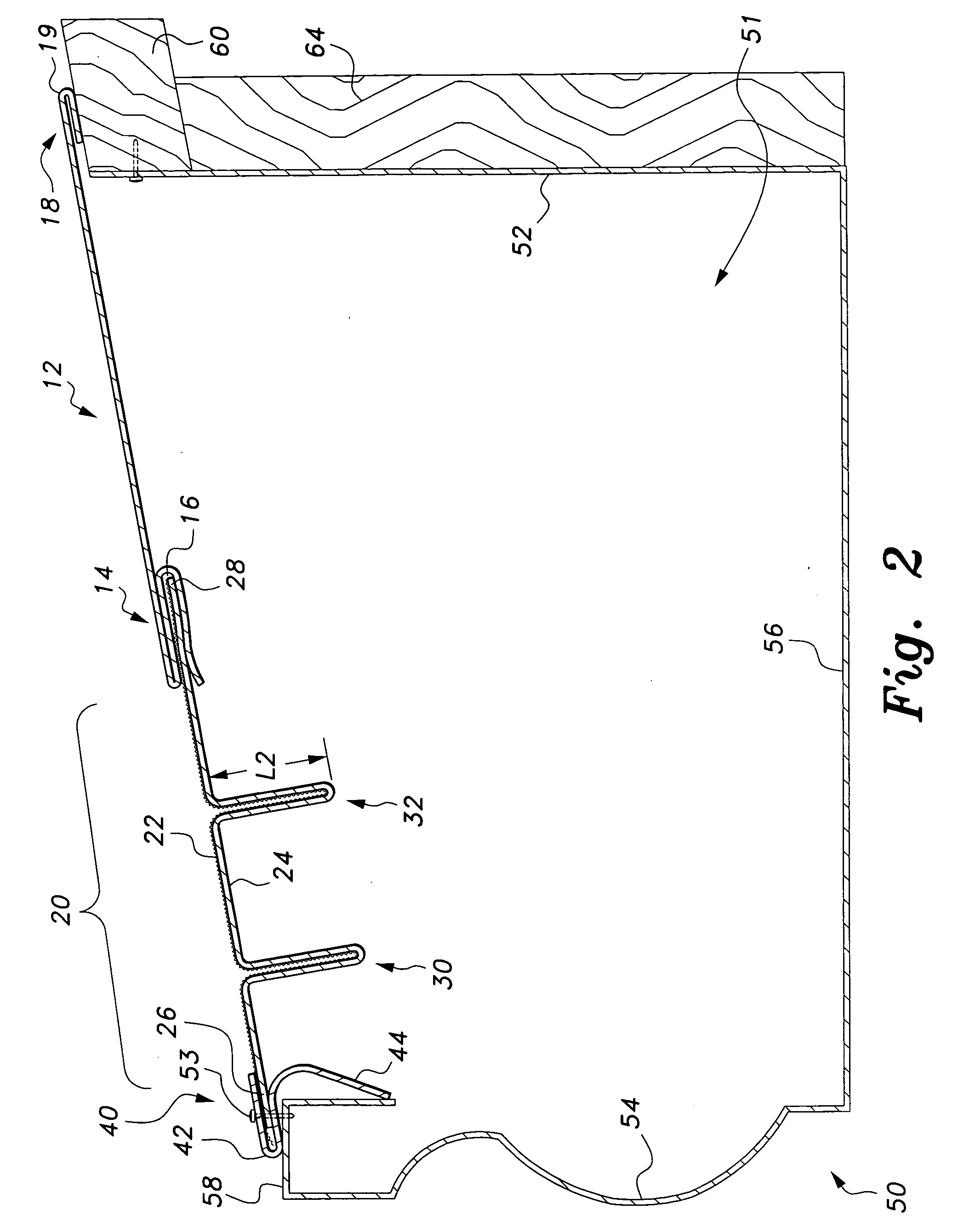

[0016] The present invention is a gutter debris screen. the screen is designated as 10 in the drawings and shown in FIGS. 1-3. As shown in FIGS. 1-2, the screen 10 lies over the open top of a gutter 50. The gutter 50 has a rear wall 52, a front wall 54, a front ledge 58 extending inward from the front wall 54, and a bottom wall 56 connecting the rear wall 52 with the front wall 54. The walls 52, 54, and 56 form a generally U-shaped gutter channel 51. The gutter 50 is attached to fascia 64 adjacent a roof sheath or panel 60 having fiberglass, asphalt, or other lightweight shingles 62.

[0017] The screen 10 rests under the shingles 62 on the roof panel 60, and the other end abuts the front ledge 58 of the front wall 52 of the gutter 50.

[0018] The screen 10 includes a rear mounting portion 12, a central screen portion 20 and a front mounting portion 40. The central screen portion 20 includes a fine mesh top layer 22 disposed over a bottom support layer 24 of expanded metal having a coar...

second embodiment

[0026] Referring now to FIGS. 4-6, the gutter debris screen, designated as 100, is shown for use on a building having heavy shingles 162, such as metal or tile shingles, that are heavy and difficult to lift and are frequently non-flat, being bent, arched, or corrugated. The gutter 150 has a rear wall 152, a front wall 154, a front ledge 158 extending from the front wall 154 and a bottom wall 156 connecting the rear wall 152 with the front wall 154. The walls 152, 154, and 156 form a gutter channel 151. The rear wall 152 of the gutter 150 is attached to a building wall 164 just below the shingles 162.

[0027] The screen 100, like screen 10, has a central screen portion 120 that is flanked by a rear mounting portion 112 and a front mounting portion 140. Here, however screen 100 has a width L3 of about four and a half inches. The central screen portion 120 of the screen 100 includes a fine mesh top layer 122 disposed over a bottom support layer 124 of expanded metal. The fine mesh layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com