Laminate flooring panel bevel and method of manufacturing same

a technology of laminate flooring and bevels, which is applied in the field of laminate flooring, can solve the problems of incongruous bevels, time-consuming operation, and the inability of adjoining laminate flooring pieces to match the bevels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

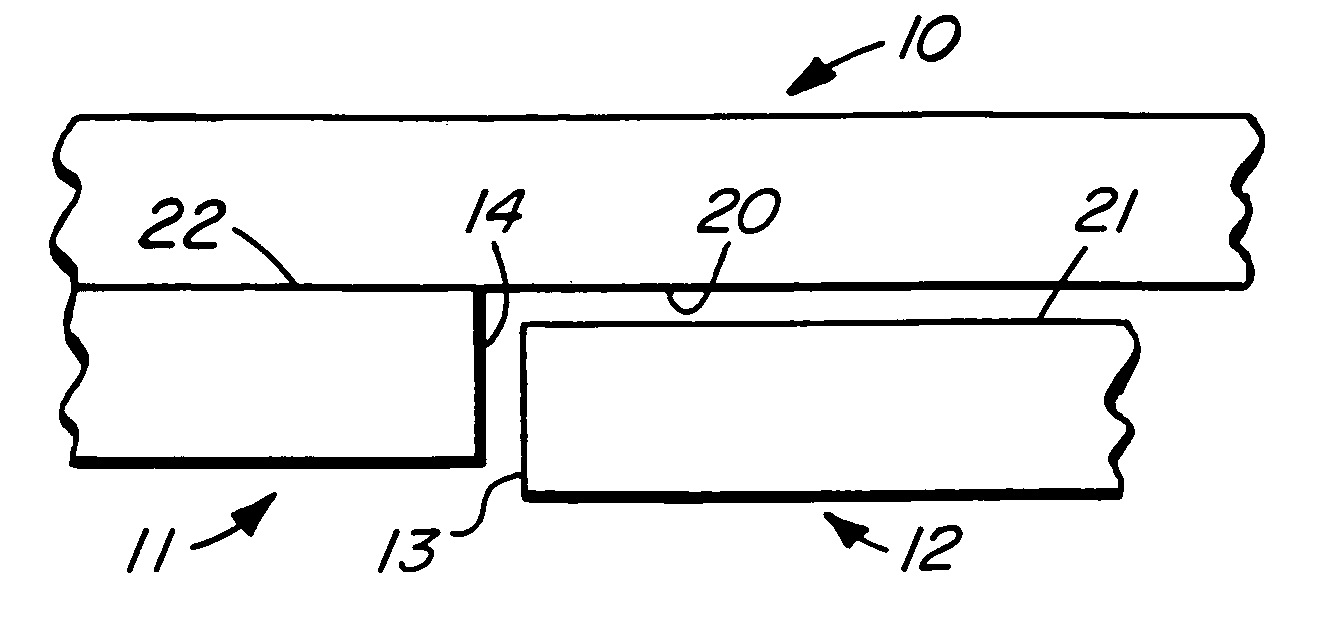

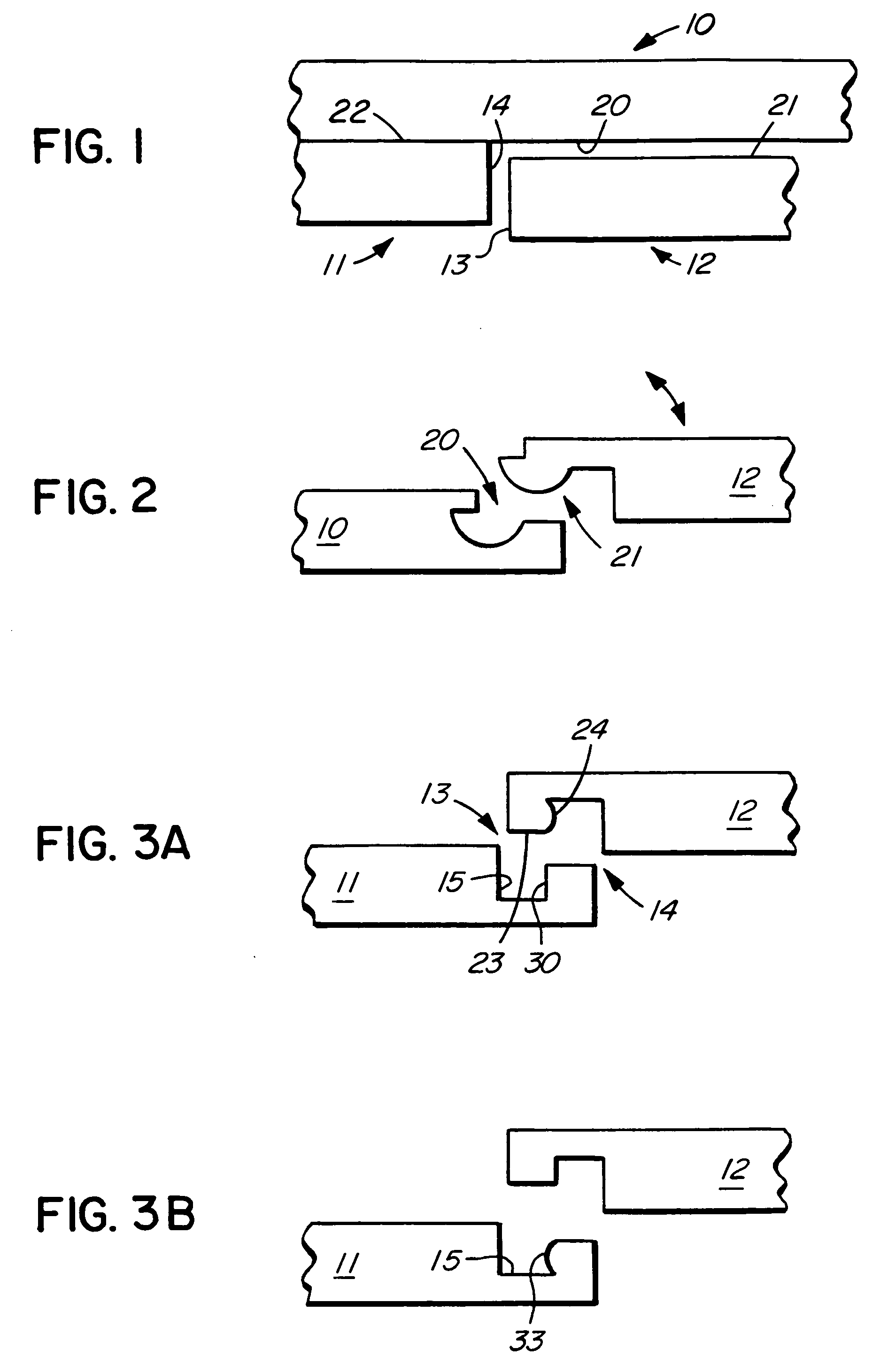

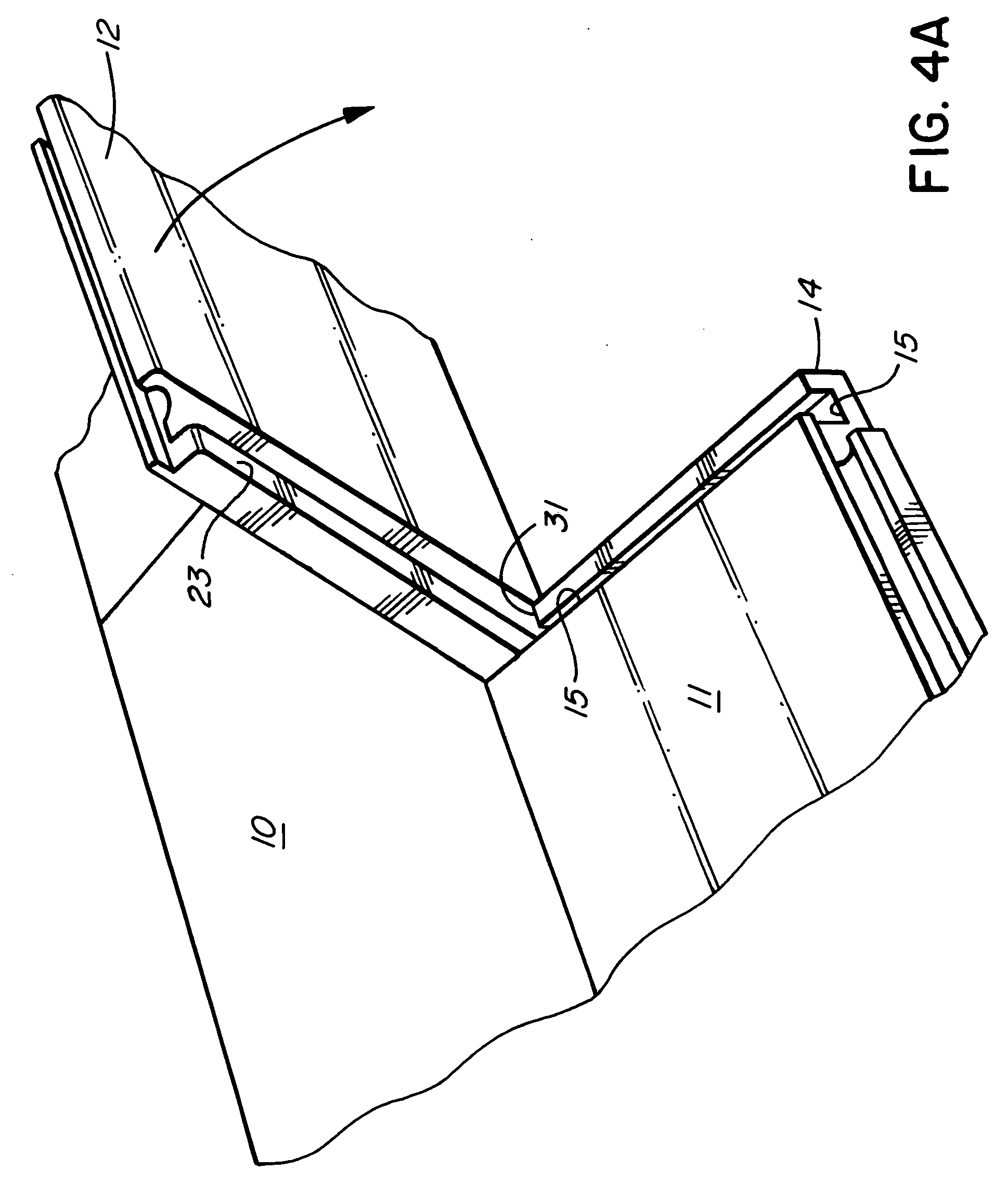

[0019] Referring now to the drawings, three(3) adjacent pieces of laminate flooring, namely first piece 10, second piece 11 and third piece 12 are illustrated in FIG. 1 which pieces are illustrated in their unassembled condition and which pieces 10, 11, 12 are intended to be joined together in an integral assembly on the top of a floor and which pieces illustrate the connection and the operation of the connection procedure according to the invention.

[0020] Each of the three pieces 10, 1112 have short and long edges, the short edges of first piece 10 not being illustrated for efficacy. Third piece 12 has a short edge 13 and second piece 11 has a short edge 14. First piece 10 has a long edge 20 which is intended to be connected to long edge 21 of third piece 12 and which long edge 20 is shown already connected to second piece 11 along long edge 22.

[0021] The connection area along the long edges 20, 21 of the first and third pieces 10, 12 are illustrated in greater detail in FIG. 2 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com