Motorized fingernail filing assembly

a motorized and fingernail technology, applied in the field of fingernail filing assembly, can solve the problems of unsightly and unsanitary consequences, items involve some effort, and clippings can still be difficult to dispose o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

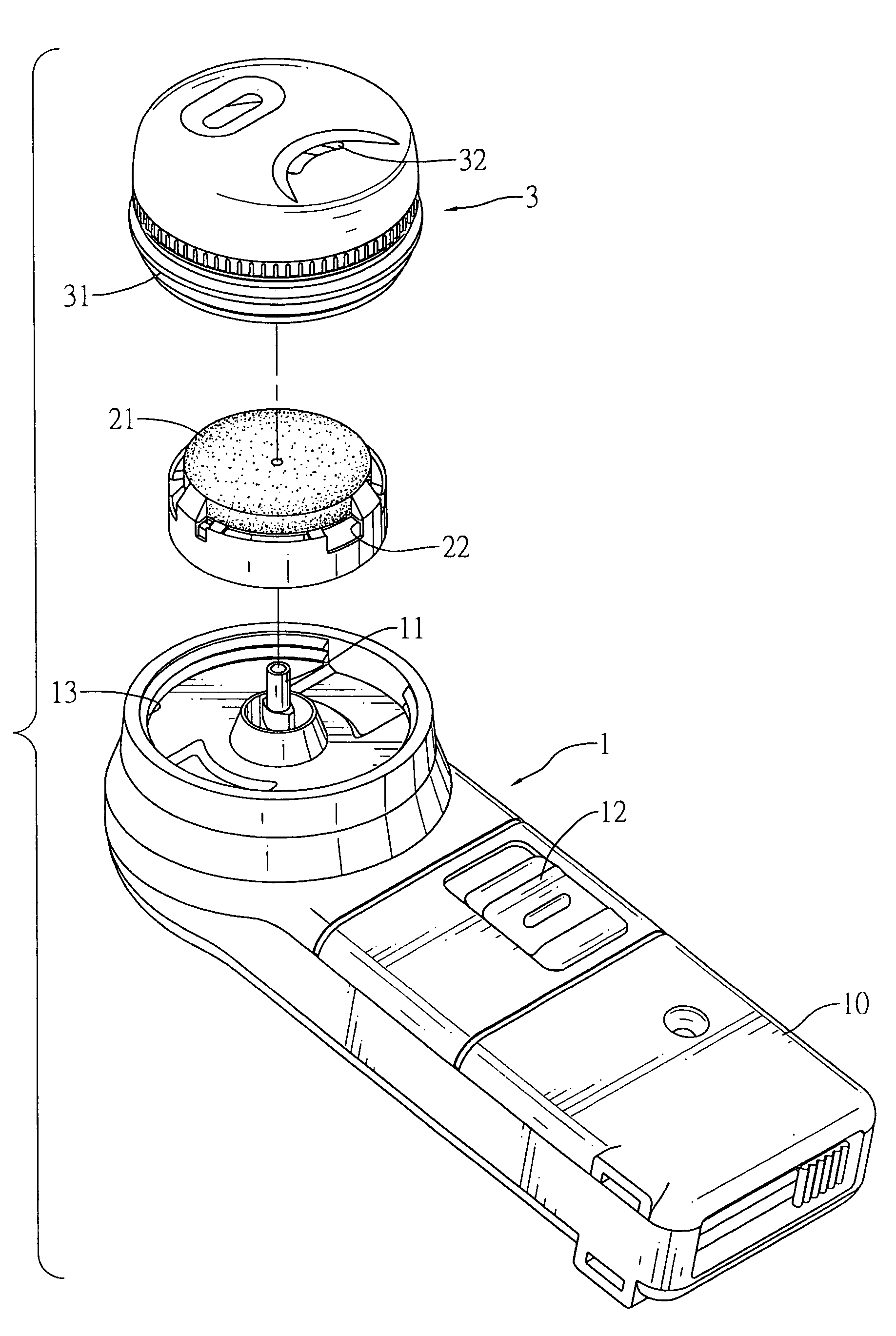

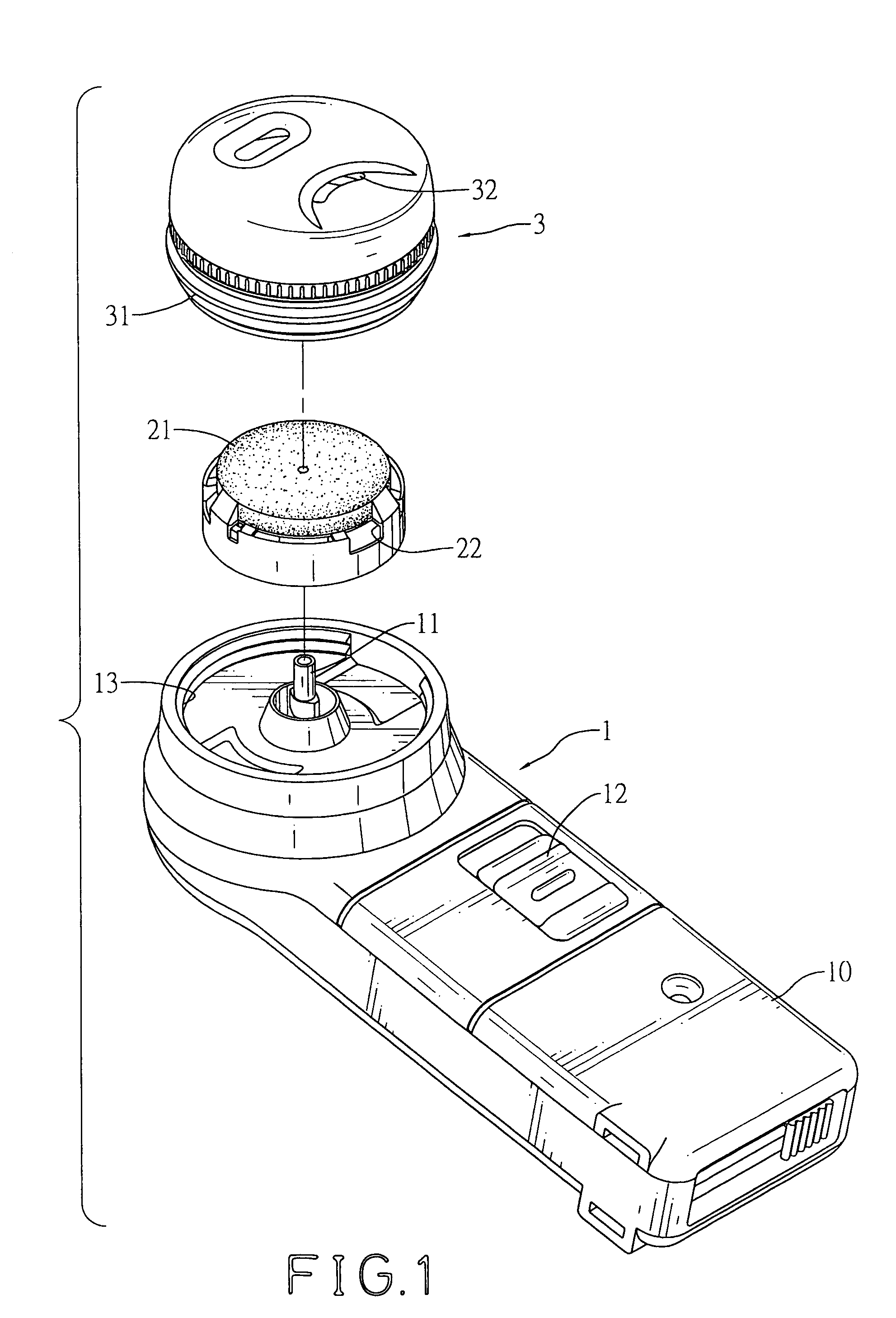

[0015] With reference to FIG. 1, it is noted that the motorized fingernail filing assembly in accordance with the present invention includes means for providing power, a rotation seat (2) and a cover (3). The power means may be anything having an ability to rotate an axle (11) extending out of the power means. In this embodiment, the power means (1) is provided with a casing (10) and a switch (12) slidably mounted on the casing (10). The axle (11) is activated to rotate when the switch (12) is slid manually from an ‘off’ mode to an ‘on’ mode.

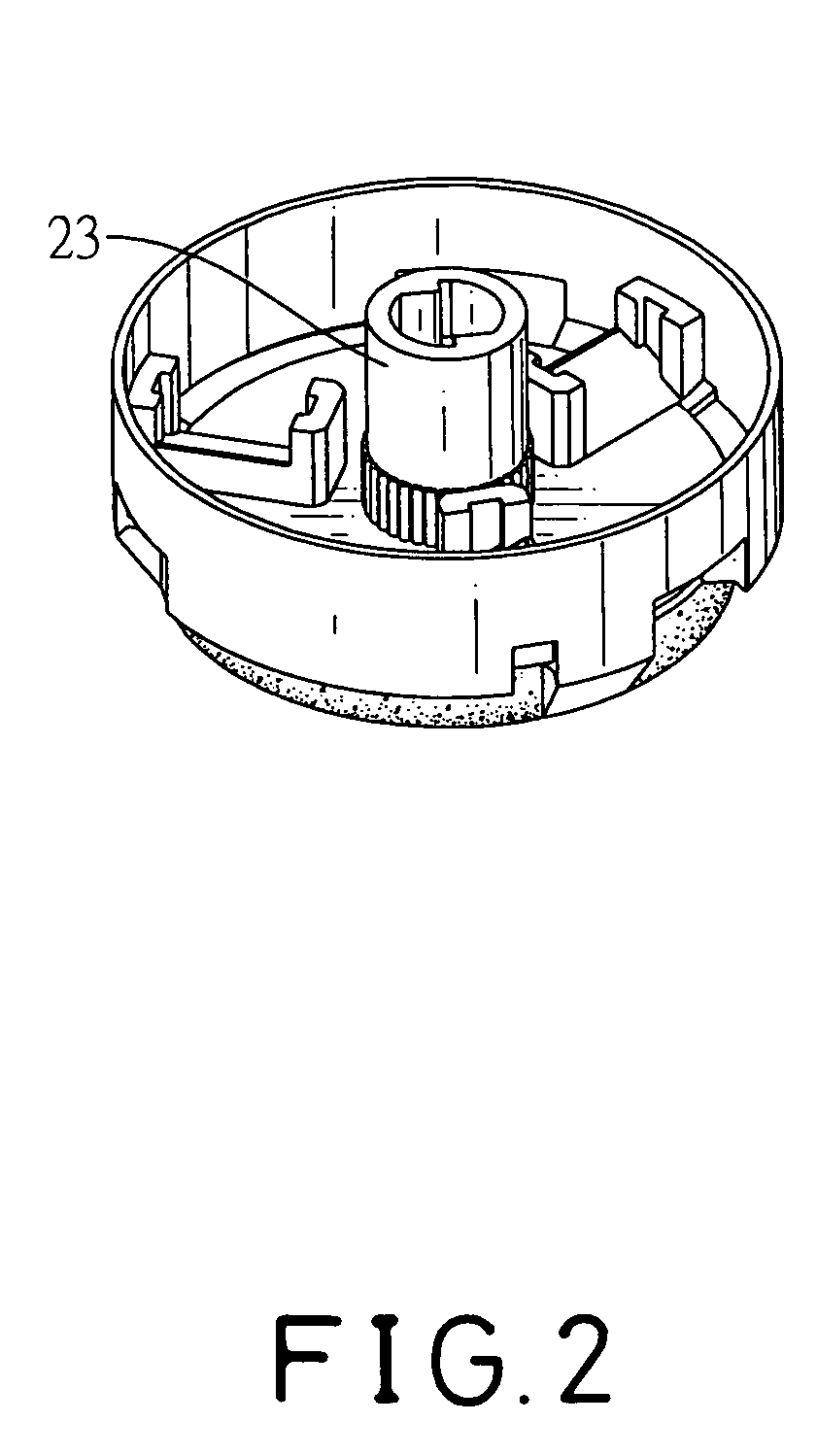

[0016] With reference to FIG. 2 and still taking FIG. 1 for reference, it is noted that the rotation seat (2) has a grinding stone (21) securely mounted on the rotation seat (2), and escape holes (22) defined in a peripheral wall of the rotation seat (2) to allow communication between an interior of the rotation seat (2) and the ambient air. Further, the rotation seat (2) has a hollow mounting collar (23) extending from an inner face of the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com