Vacuum cleaner with dirt collection vessel having a stepped sidewall

a vacuum cleaner and dirt collection technology, which is applied in the direction of vacuum cleaners, cleaning filter means, domestic applications, etc., can solve the problems of affecting the cleaning efficiency of vacuum cleaners, and entrapping dirt and debris in airstreams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

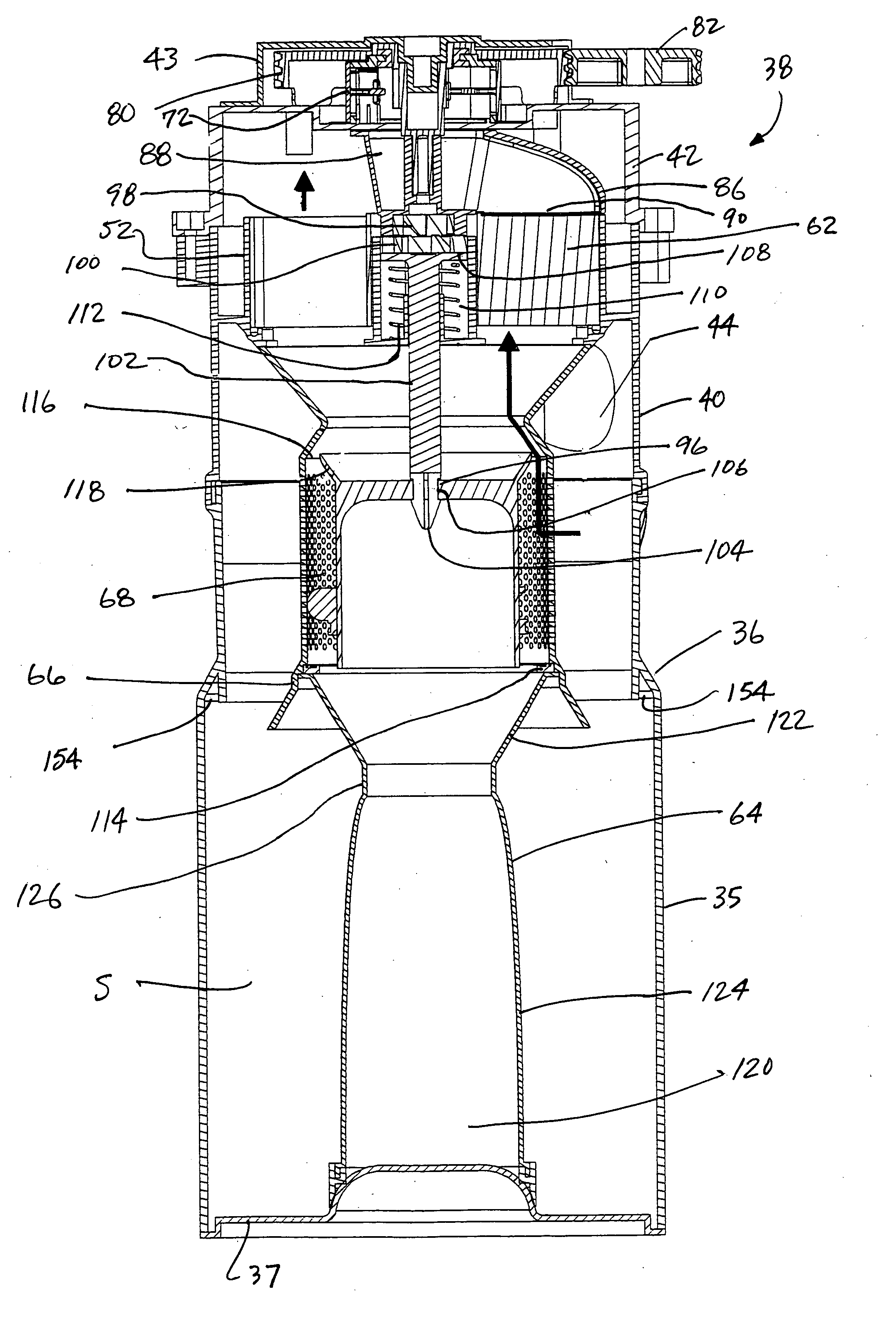

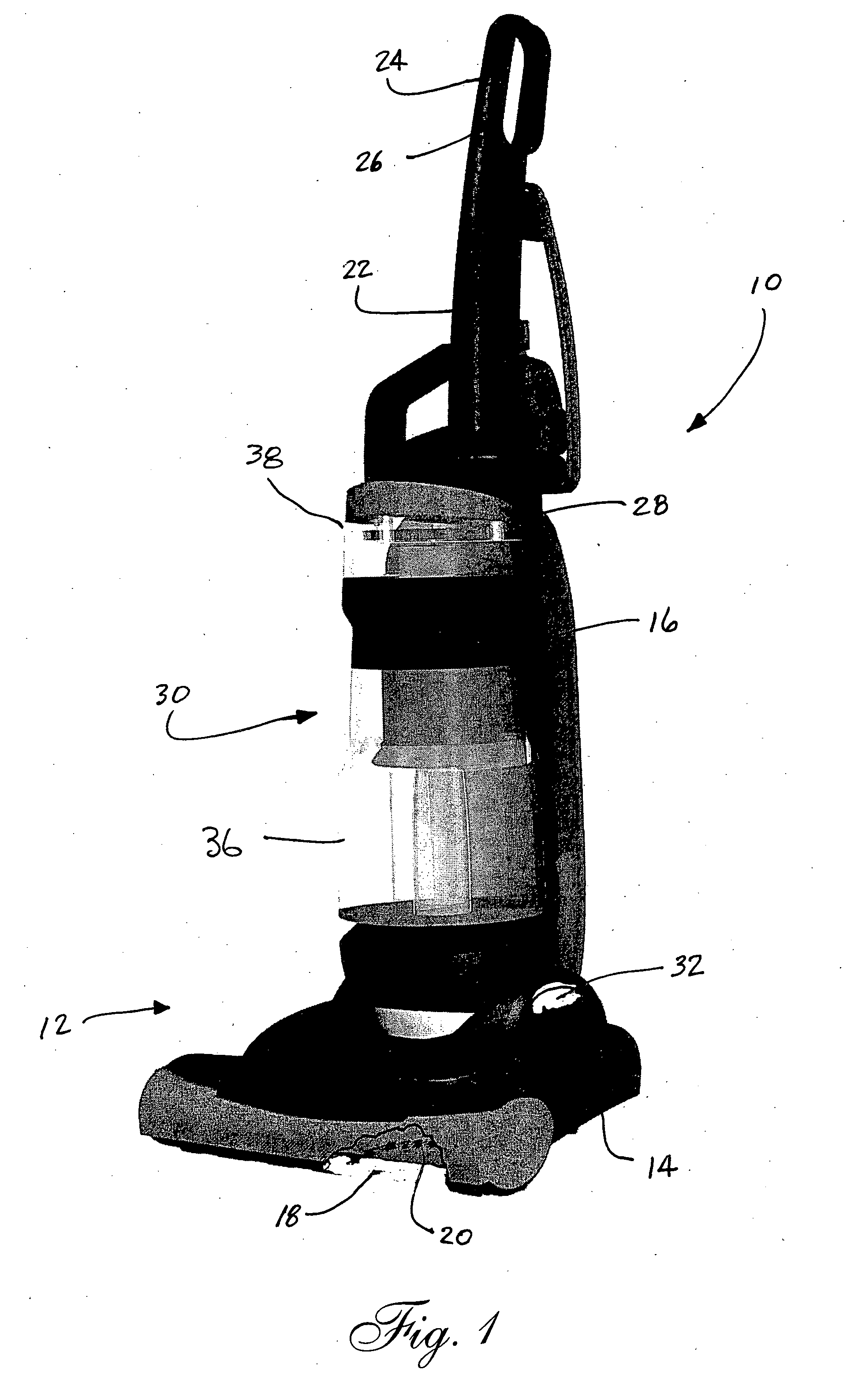

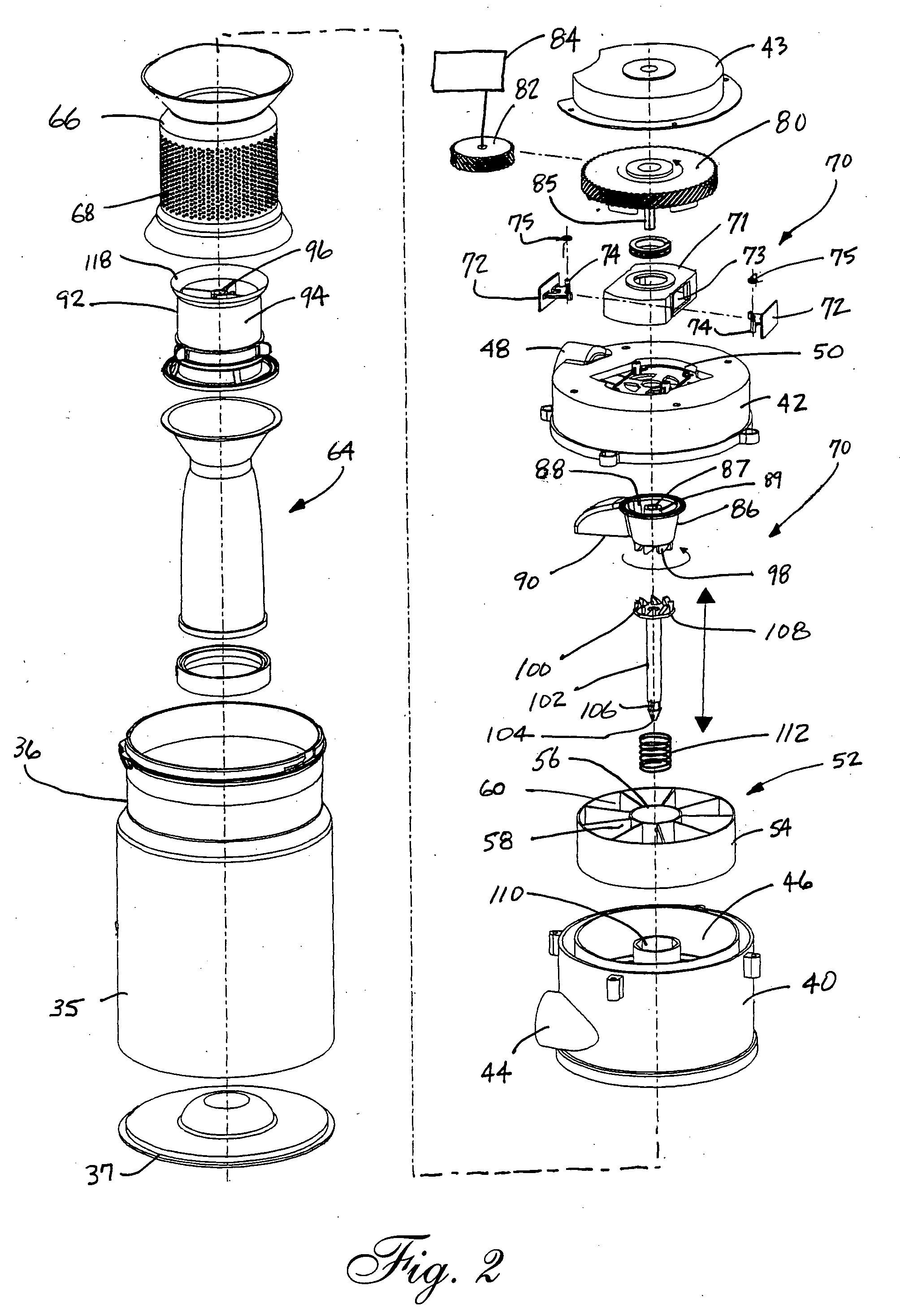

[0025] Reference is now made to FIG. 1 which illustrates the floor cleaning apparatus 10 of the present invention. In the illustrated embodiment, the floor cleaning apparatus 10 comprises an upright vacuum cleaner. It should be appreciated, however, that the apparatus 10 may just as easily be a canister vacuum cleaner or a handheld vacuum cleaner.

[0026] As illustrated, the apparatus 10 includes a housing 12 including both a nozzle assembly 14 and a canister assembly 16. The nozzle assembly 14 includes a suction inlet 18 through which air entrained with dirt and debris is drawn into the vacuum cleaner. A rotary agitator 20 is mounted to the nozzle assembly 14 and extends across the suction inlet 18.

[0027] The canister assembly 16 includes a handle 22 having a handgrip 24. An actuator switch 26 for turning the vacuum cleaner on and off is provided adjacent the handgrip. In addition the canister assembly 16 includes a cavity or receiver 28 for receiving and holding a dirt collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com