Method and apparatus for reducing femoral fractures

a technology of femoral fractures and methods, applied in the field of hip fracture treatment methods and equipment, can solve the problems of lengthening the rehabilitation time of patients, and achieve the effect of accelerating patient recovery and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

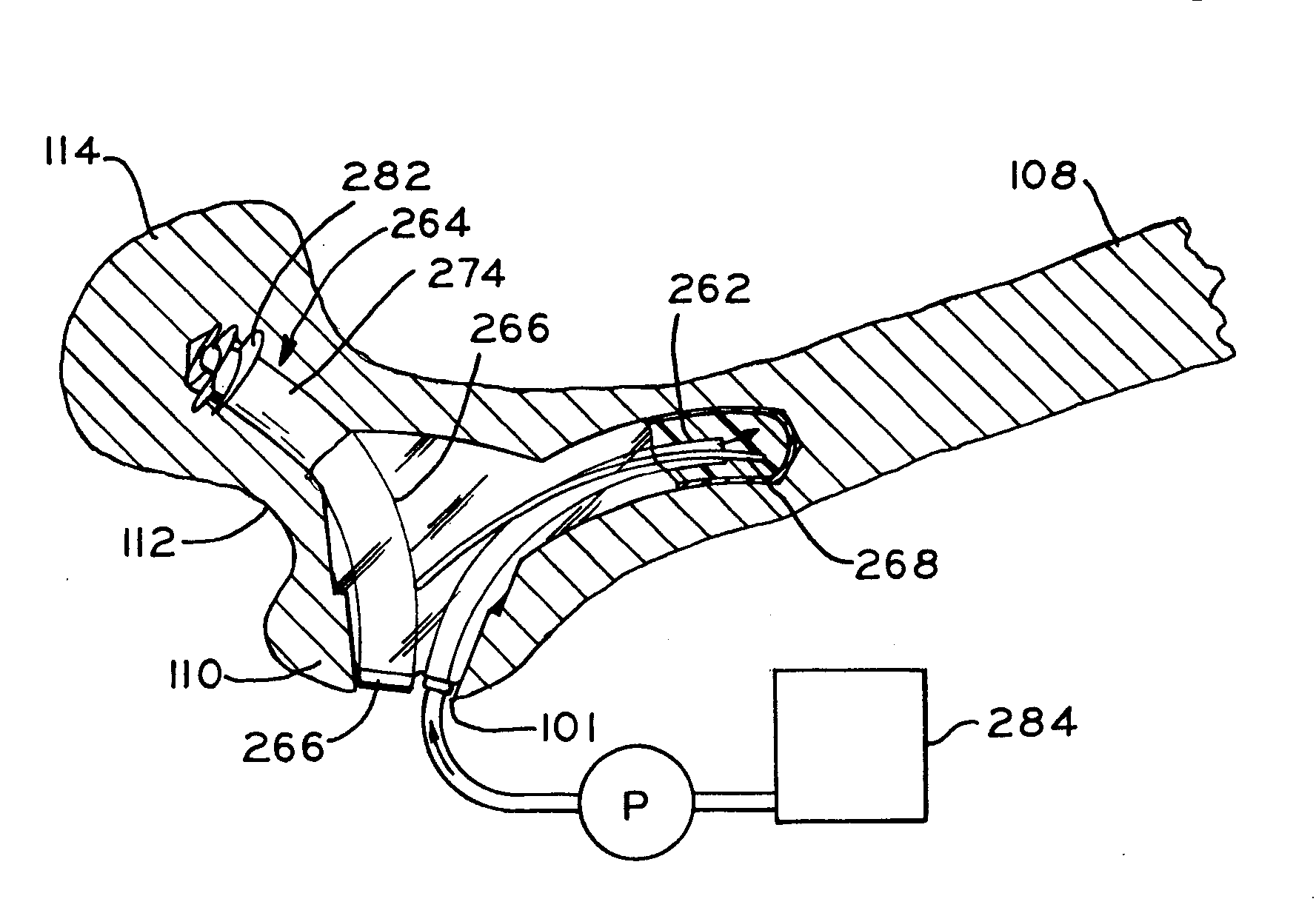

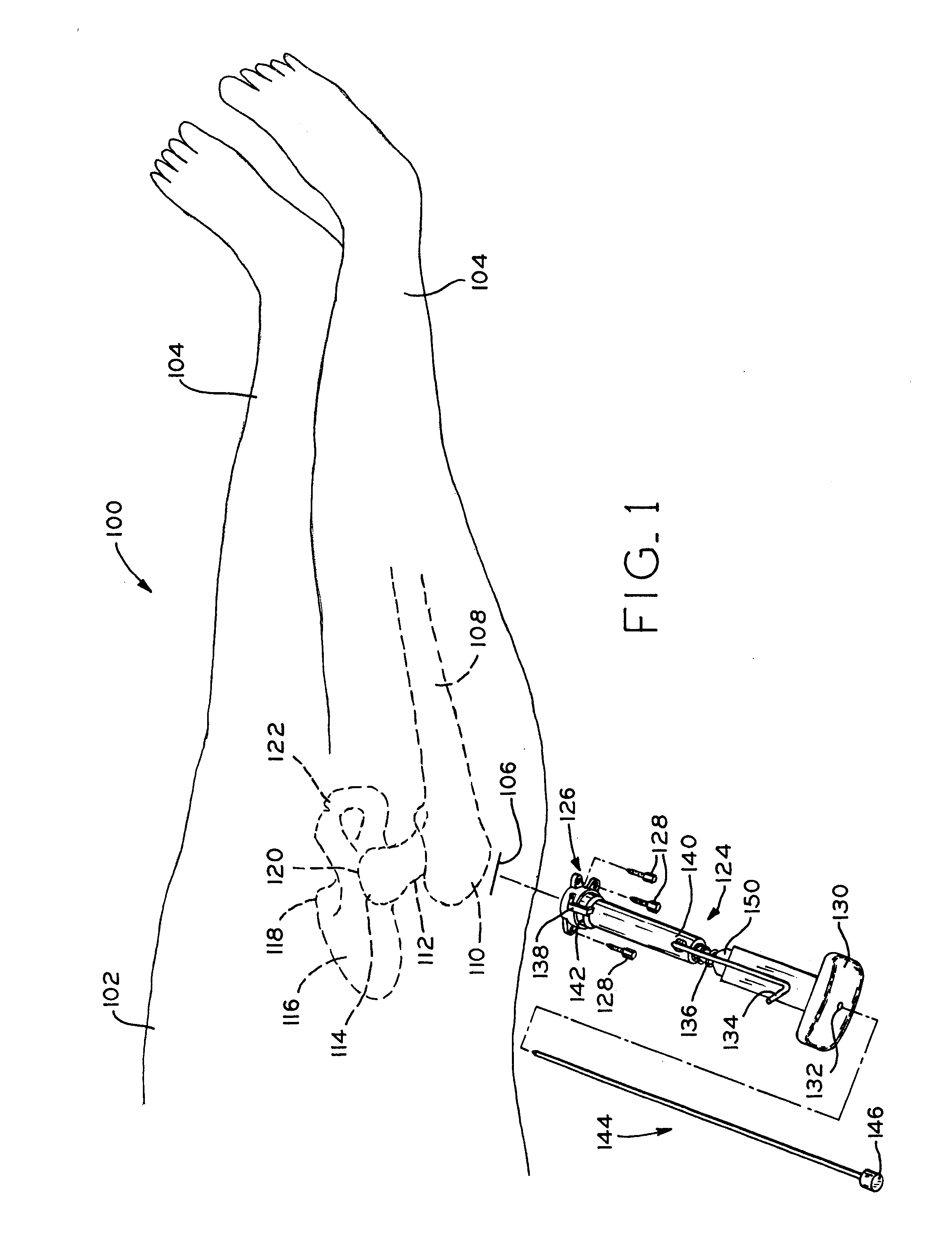

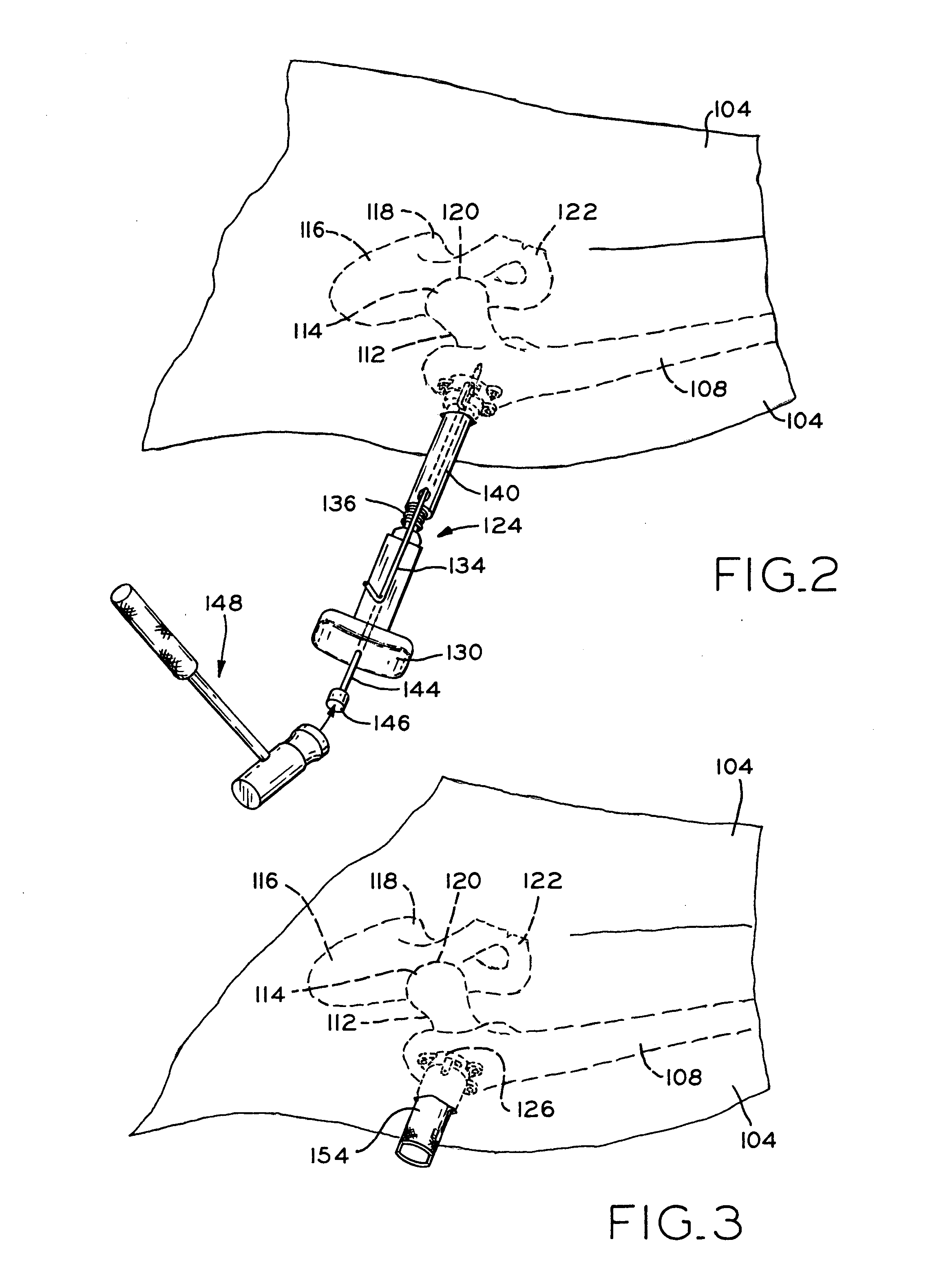

[0099] Implant 260 illustrated in FIG. 41 is utilized to reduce a femoral fracture utilizing a method of implantation which does not require incision of the quadriceps. As illustrated in FIG. 1, incision 106 is aligned with greater trochanter 110, with femur 108 being prepared to receive implant 260 through incision 106. As described above, greater trochanter 110 is not covered with muscle and therefore, incision 106 can be developed to expose greater trochanter 110 without requiring the incision of muscle. As illustrated in FIGS. 6-10, various novel reamers of the present invention are utilized to form femoral cavity 224 (FIG. 11). As illustrated in FIG. 12, implant 260 (further illustrated in FIGS. 41-43) is inserted into femoral cavity 224 via an access formed through greater trochanter 110. As illustrated in FIG. 13, lag screw 264 is advanced into femoral head 114 until lag screw threads 282 firmly engage femoral head 114 and lag screw 264 has achieved the position illustrated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com