Reinforced seamless brassiere

a seamless brassiere and seamless technology, applied in the field of reinforced seamless brassieres, can solve the problems of reducing the comfort of wearing the bra, affecting the appearance of the bra when worn, and increasing the weight of the bra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

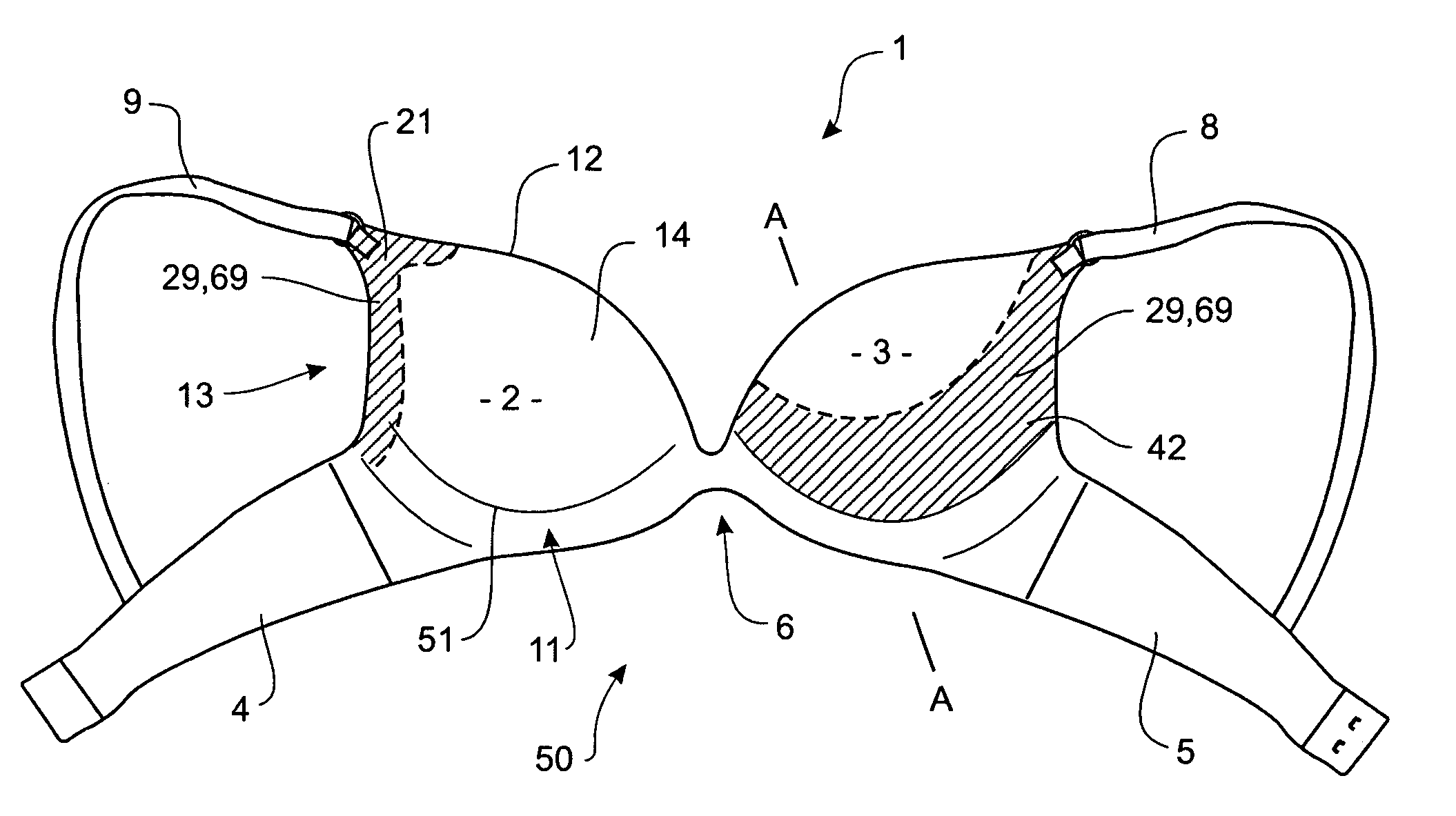

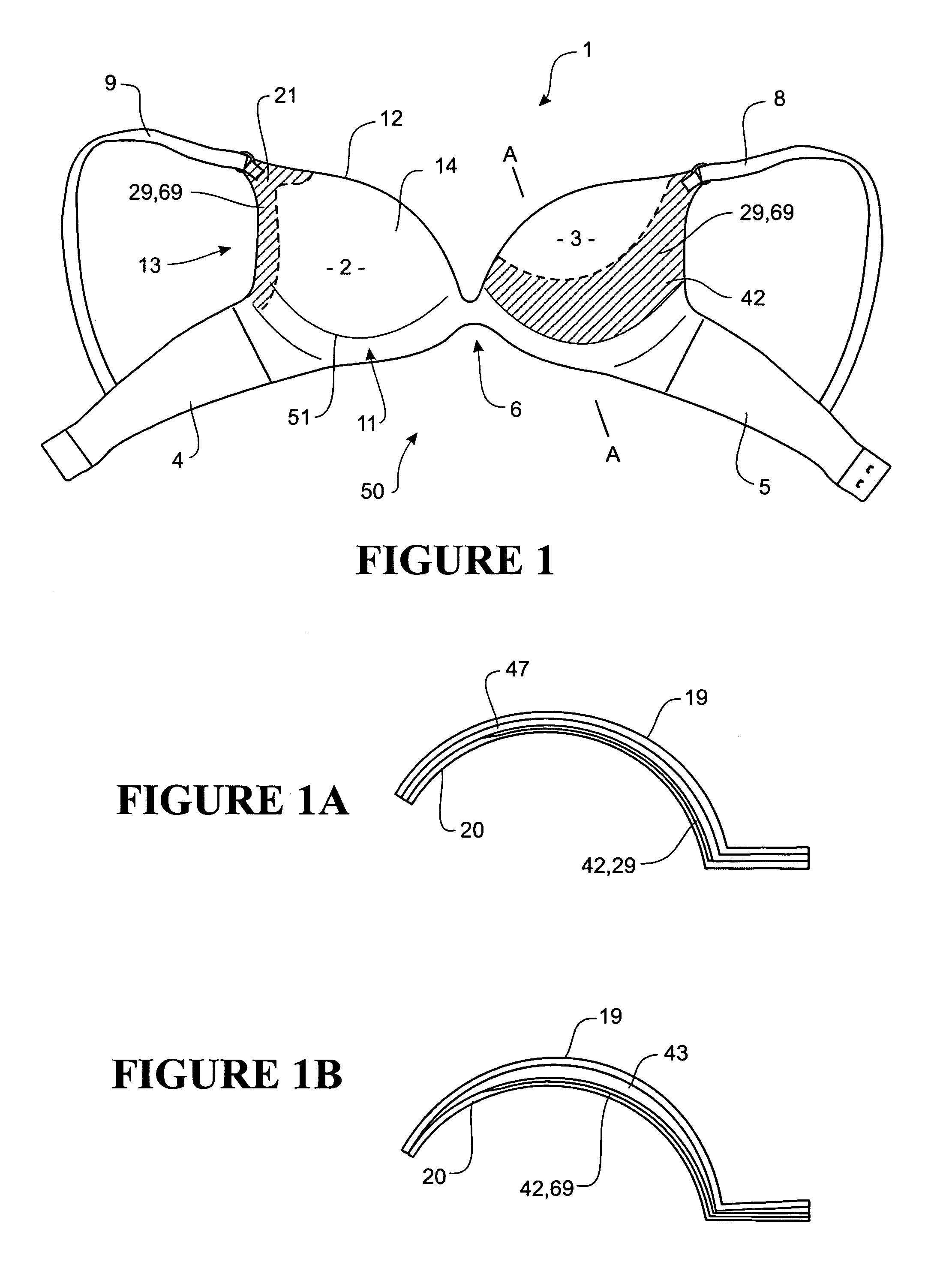

[0075]For the first embodiment, there are only two plies of fabric material laminated or substantially laminated to each other. They constitute the outer and inner layers of the bra. The reinforcing member 29 is interposed between the two fabric plies 19 and 20 as shown in FIG. 1a. The fabric plies are laminated or substantially laminated to each other and molded to the cup shape. Because two fabric plies alone generally do not provide sufficient support to counter the tensile force of, for example, the left breast cup moving from the centre to the left when the bra is in use, the reinforcing member 29 is preferably provided.

[0076]In a preferred form the reinforcing member 29 is a hot-melt adhesive film such as Bemis 3410. This is a thermoplastic adhesive film sometimes also known as a hot-melt film or thermo sensitive film. The reinforcing member 29 is preferably transparent and not conspicuous through the relatively thin fabric plies 19, 20.

[0077]In the first embodiment, where the...

second embodiment

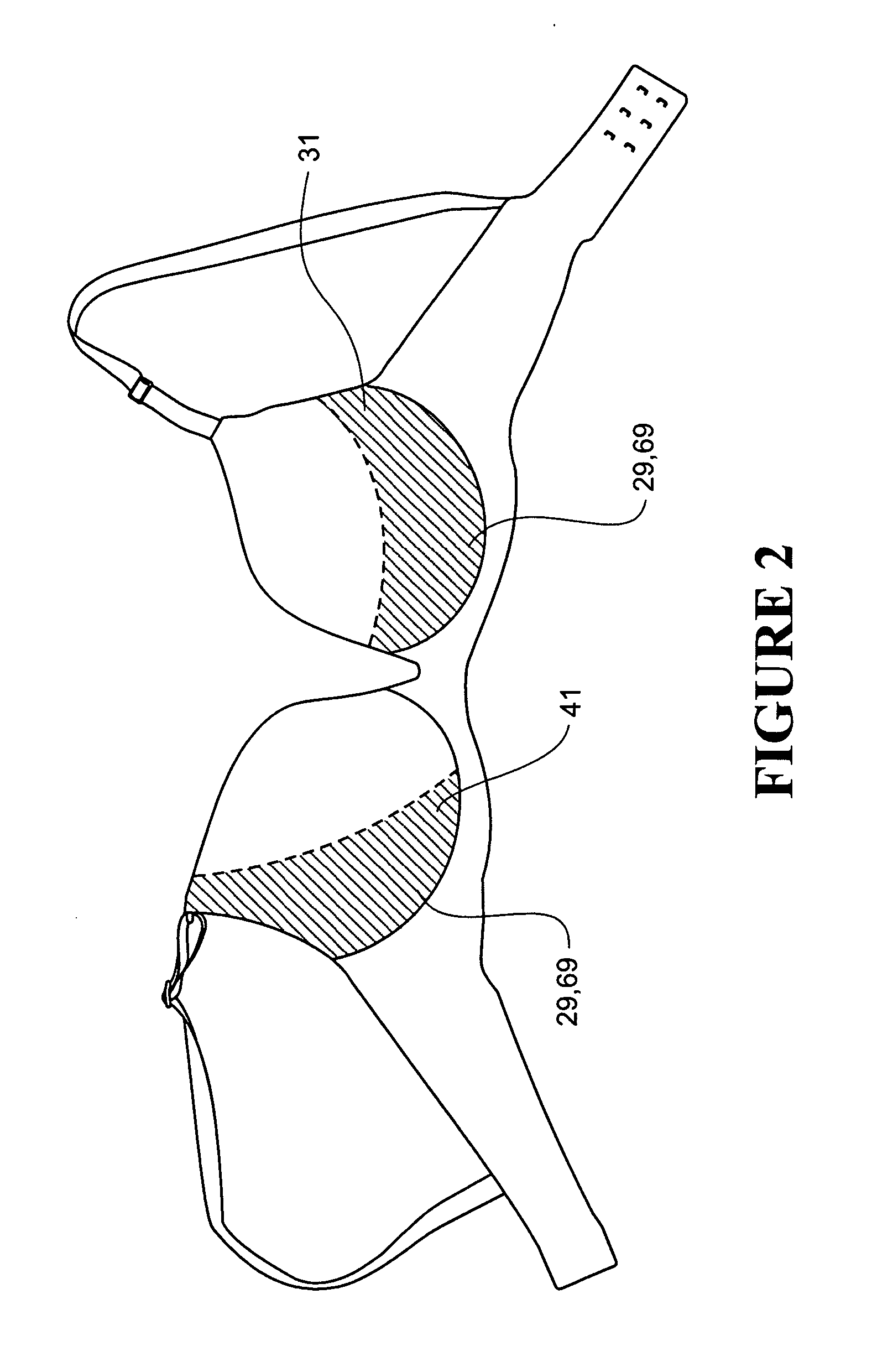

[0083]In this second embodiment, reinforcement zones 21, 31, 41 and / or 42 are preferably provided by a reinforcing member 69 which is a non-stretchable fabric. Again, non-stretchable is understood to mean substantially non-stretchable rather than absolutely or perfectly non-stretchable.

[0084]For the second embodiment, at each cup 2, 3 there are at least two laminated plies—for example the outer ply 19 and the inner ply 20—which capture at least a foam ply 43. The inner and outer plies 19 and 20 are preferably fabric plies which may for example be spandex. This is shown in FIG. 1b.

[0085]In the second preferred embodiment, where there is at least one foam ply 43 laminated with the outer fabric ply 19, the reinforcing member 69 is preferably a non-stretchable fabric such as non-woven fabric. However it could alternatively be a hot-melt adhesive film of a kind as mentioned when the first preferred embodiment is described.

[0086]In the second embodiment, the reinforcing member 69 is pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com