Breathable-waterproof footwear

a technology of breathable waterproof footwear and waterproof material, which is applied in the field of footwear, can solve the problems of high construction cost, high cost of breathable waterproof material used for the liner, and complicated and expensive manufacturing, and achieve the effects of easy carrying out, low or no water penetration risk, and increased comfort for wearers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

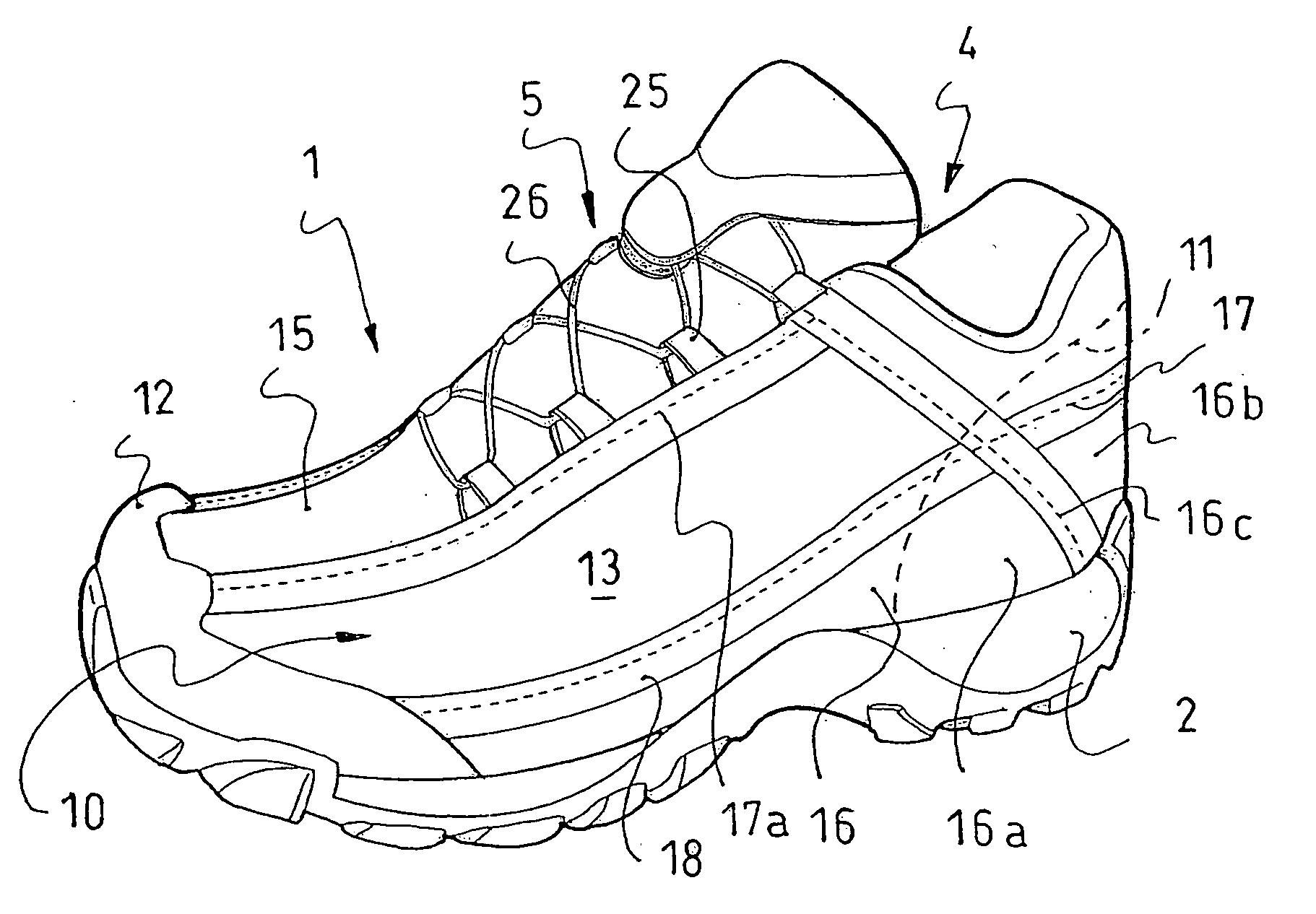

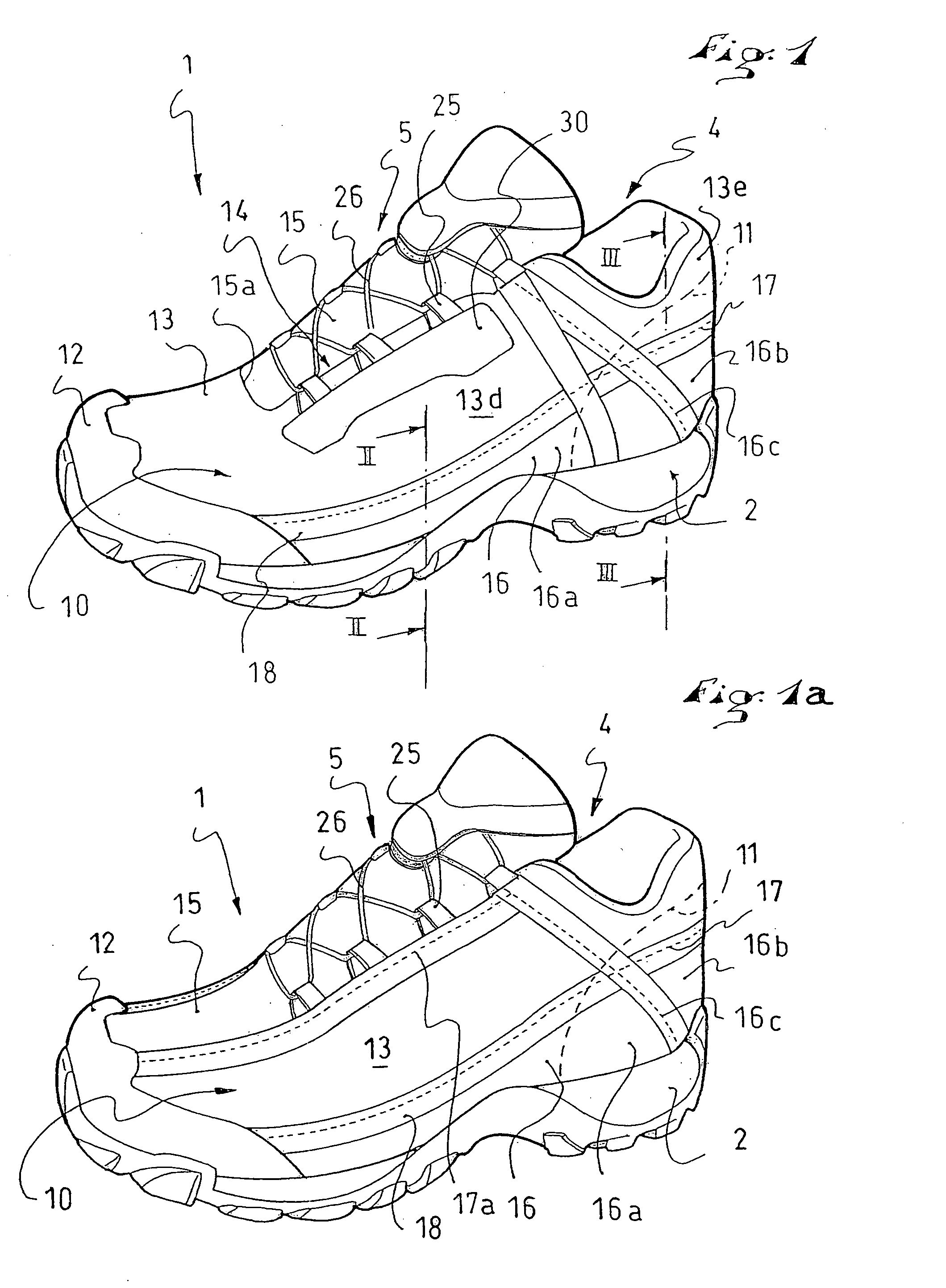

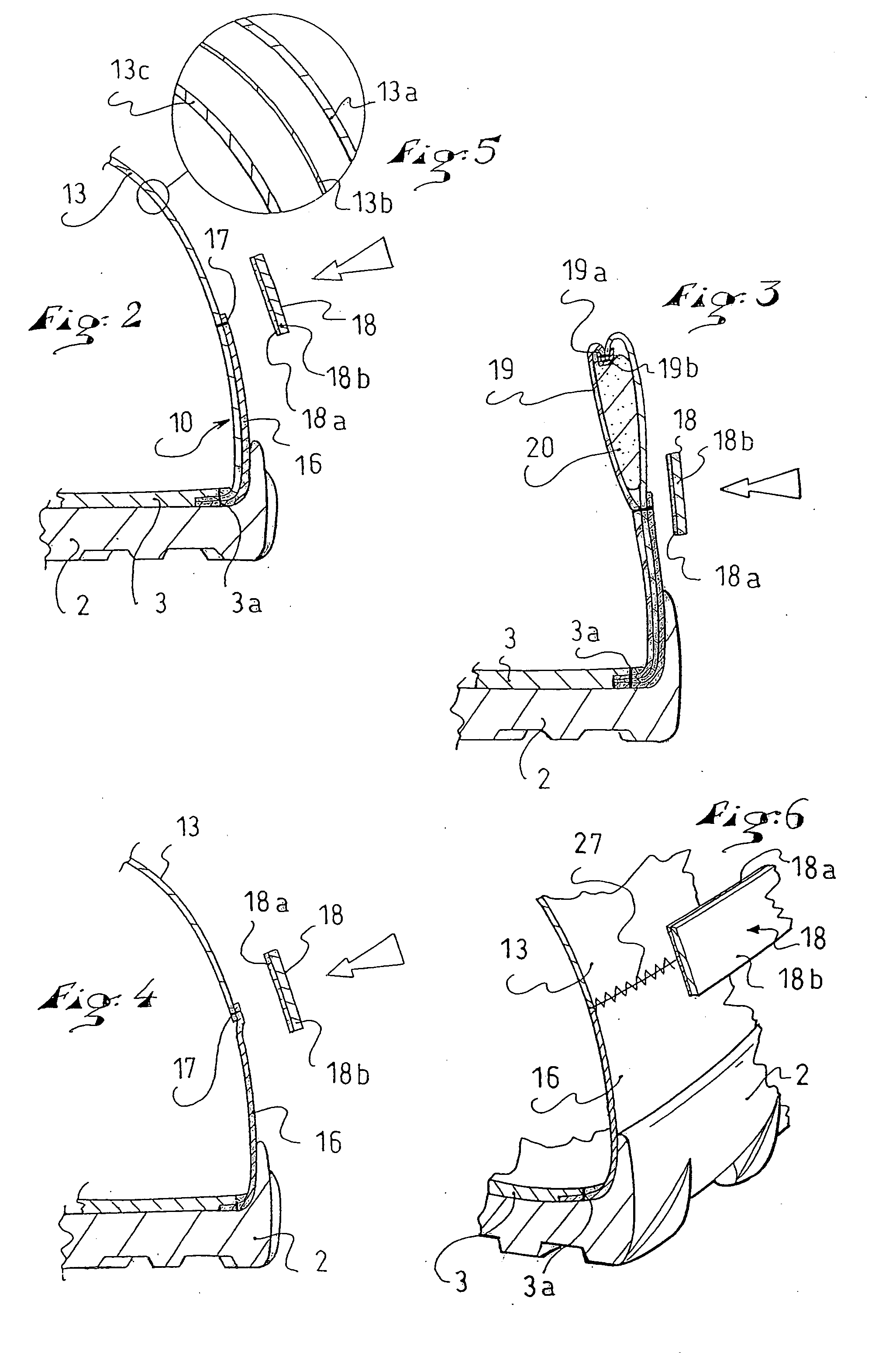

[0033]FIG. 1 shows a shoe, in this case a sports shoe 1, made of an outer upper 10, an outer sole 2, the upper 10 being capable of being mounted on the outer sole 2 by any known technique, for example by gluing, overmolding, or other technique. Although the term “shoe” is used in describing the illustrated embodiments of invention, the term is not intended to be limiting, i.e., the invention encompassing footwear in general, including that which include upper edges that lie beneath the ankle, those at the ankle, and those that extend above the ankle.

[0034]The upper 10 of the shoe is substantially a flexible upper, that is, formed of primary pieces of flexible material, or relatively flexible materials, while including complementary rigid or semi-rigid elements, particularly for shaping the shoe. Such complementary materials particularly include a heel stiffener 11, arranged inside the upper 10 and shown in broken lines in FIG. 1, and a front end piece 12, arranged at the front end o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap