Dust vacuuming abrasive tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

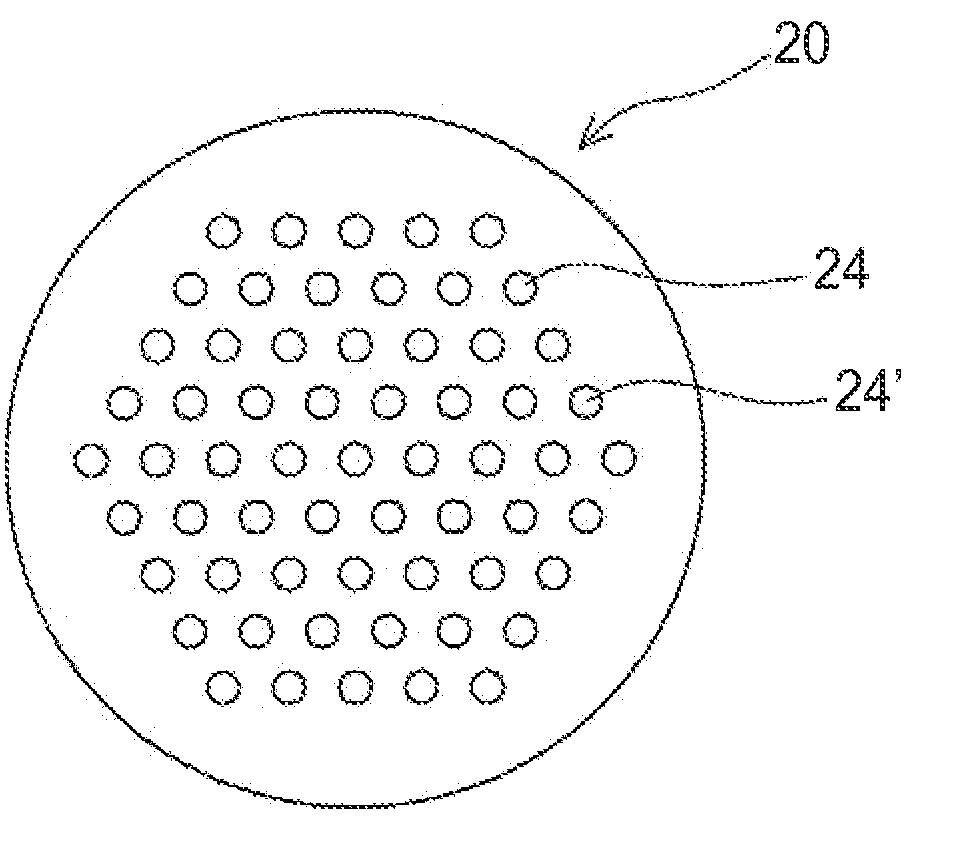

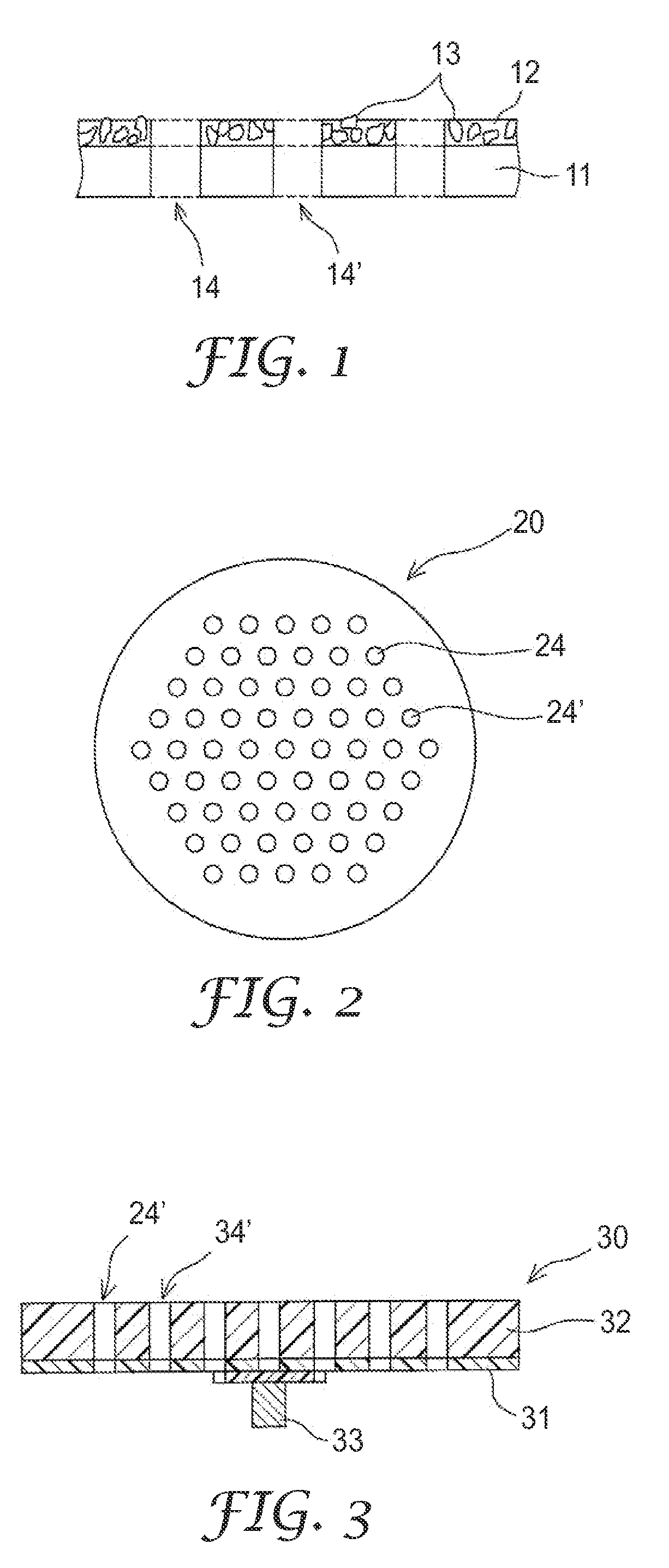

[0072] A nylon pile loop material of a mechanical fastener was attached to the back surface of an abrasive material “Disc Unicut P400” having a diameter of 125 mm, made by Sumitomo 3M Ltd. Perforations were formed in the abrasive material to form an opening structure shown in FIG. 2. Thus, an abrasive sheet material was obtained. The total number of circular perforations was 61, all having a diameter of 5.0 millimeters (mm). The centers of three adjacent perforations form an equilateral triangle of length. The distance between adjacent perforations is 6.8 mm.

[0073] A 10 mm-thick sponge sheet was punched into a circle 125 mm in diameter. A hook material of a mechanical fastener was attached to the supporting surface of the resultant sponge disc and a loop material of the mechanical fastener was attached to the back surface. Perforations were formed in the disc material to form an opening structure shown in FIG. 2. Thus, an intermediate pad was obtained. The 5.5 mm diameter perforati...

example 2

[0081] In the supporting surface and back surface of an intermediate pad prepared in the same manner as in Example 1, channels were formed along lines connecting the perforations in concentric loops. FIG. 9 is a diagram showing the support surface and the back surface of the intermediate pad. The channels were formed by removing the hook element on the supporting surface and the loop element on the back surface with a width of 3 mm. A dust vacuuming abrasive tool was obtained in the same manner as in Example 1, except that this intermediate pad was used, and a sanding test performed. The results are shown in Table 3.

example 3

[0082] In the supporting surface and back surface of an intermediate pad prepared in the same manner as Example 1, channels were formed along lines completely connecting the perforations. FIG. 8 is a diagram showing the support surface and the back surface of the intermediate pad. The channels were formed by removing the hook element on the supporting surface and the loop element on the back surface with a width of 3 mm by a melting (fusion) removing method. A dust vacuuming abrasive tool was obtained in the same manner as in Example 1, except that this intermediate pad was used, and a sanding test performed. The results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com