Honing jig

a jig and honing technology, applied in the field of honing jigs, can solve the problems of tool running off the whetstone, hobbyists, and affecting the work efficiency of carpenters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

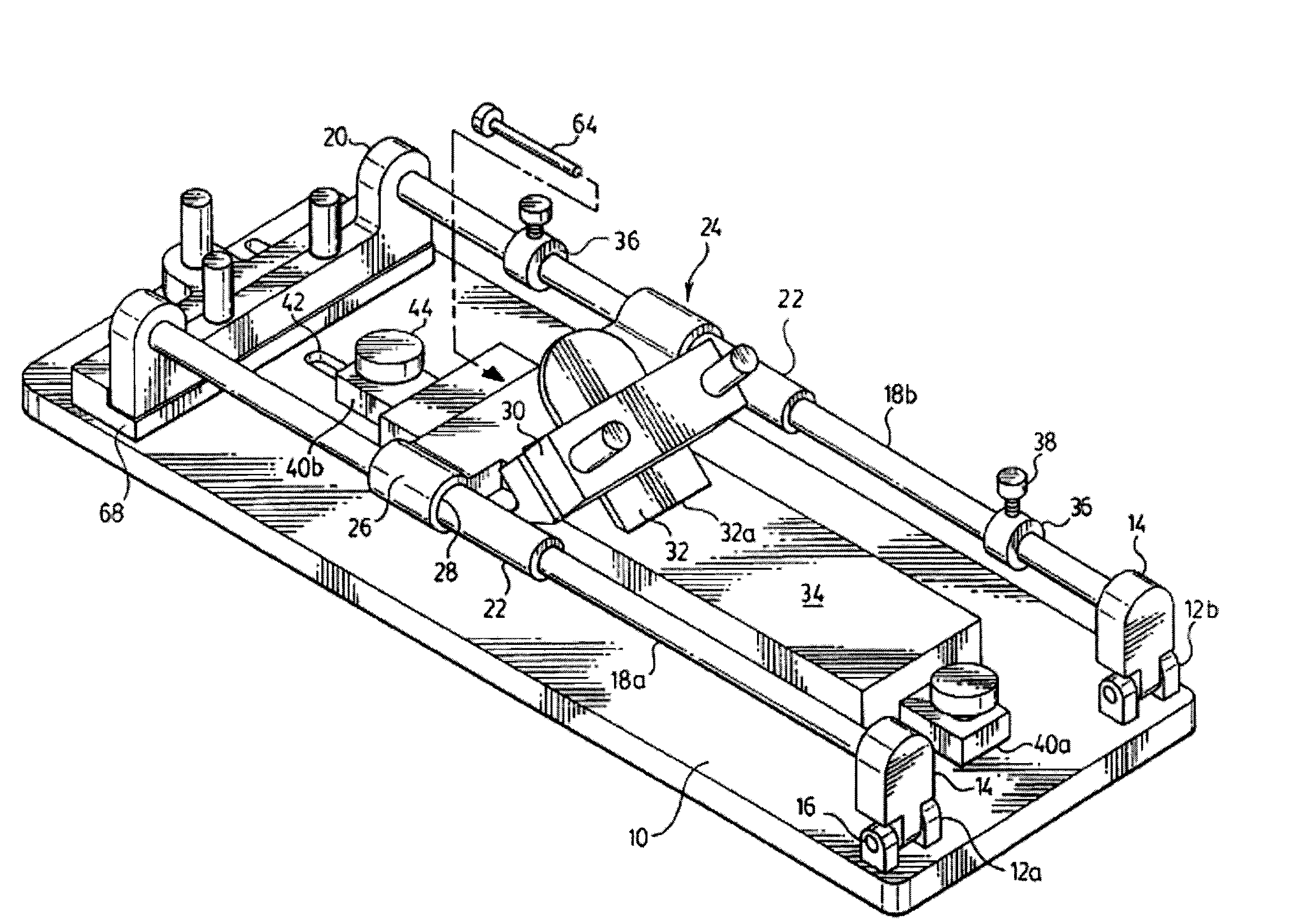

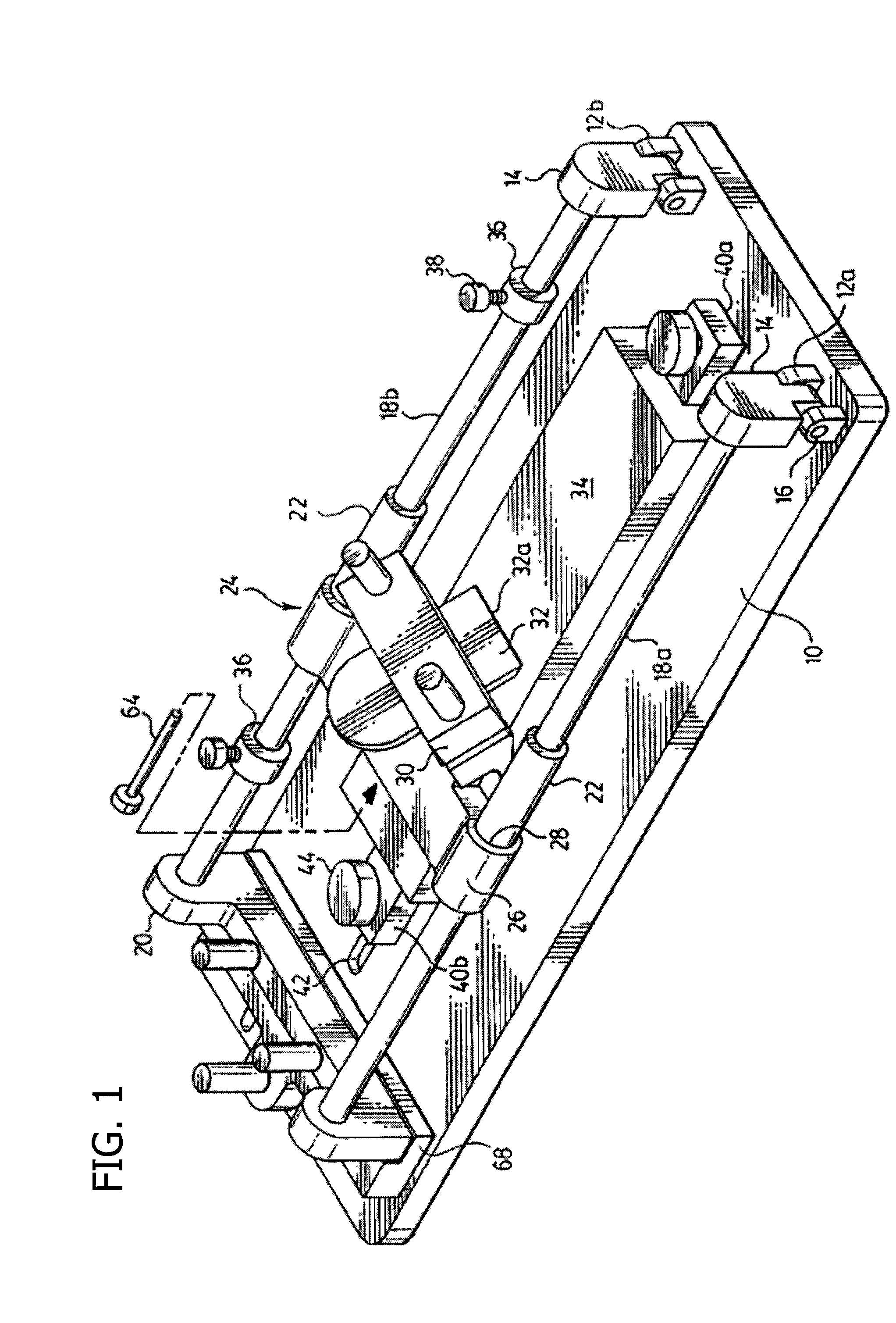

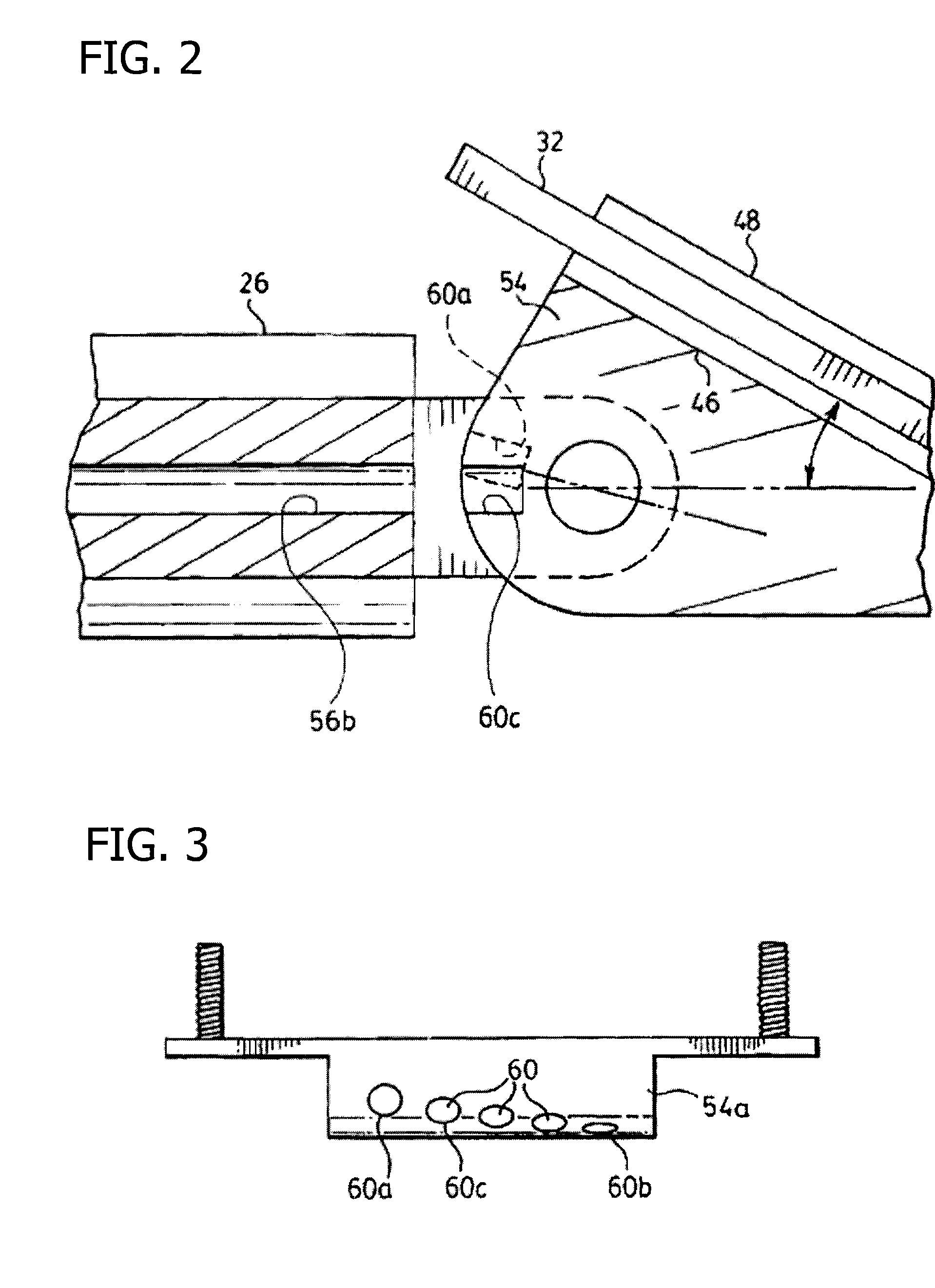

[0020]With reference to FIG. 1, the honing jig has a base 10 on which is mounted, at one end, two pairs of spaced supporting blocks 12a,b. An end member 14 has opposing trunnions 16 which extend into bores in each supporting block so that each end member is pivotal with respect to the base. An end of one of a pair of spaced guide rods 18a,b is accommodated in each end member. The opposite ends of the guide rods are mounted to a dual supporting block 20, described more fully below. A sliding tube 22 is mounted for sliding to each guide rod 18a, 18b. A carriage, indicated generally at 24 includes a transverse or adjustment plate 26 which has a passageway 28 at opposite sides for receipt of the sliding tubes. The sliding tubes 22 are pressure fitted into the passageways 28 or otherwise suitably connected so that the carriage 24 is moveable or slidable on the guide rods 18a, 18b. The carriage has a means for removably fastening a blade 32 thereto in the form of a swiveling clamp 30 whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com