Gloves with reinforcing elements and methods for making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

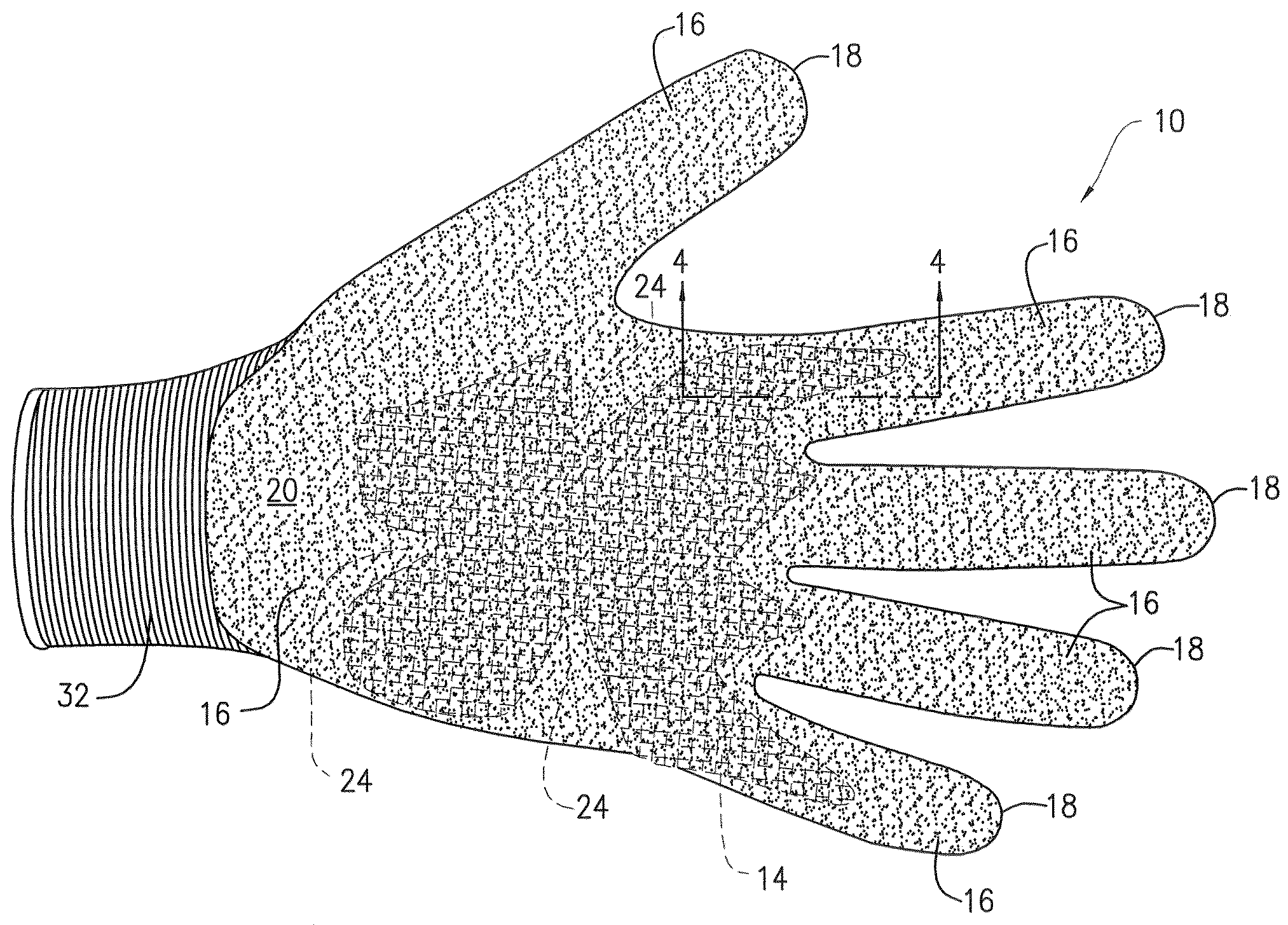

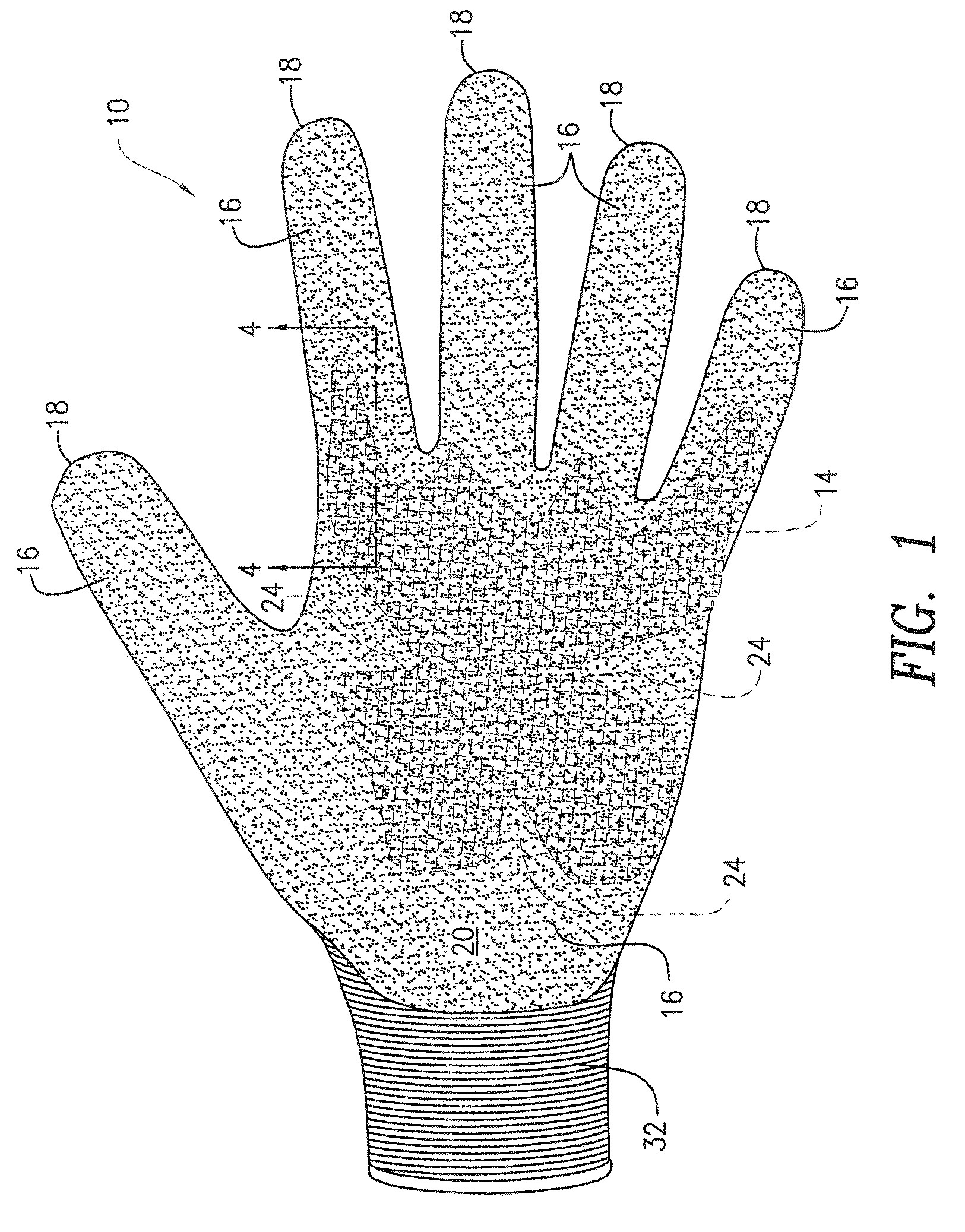

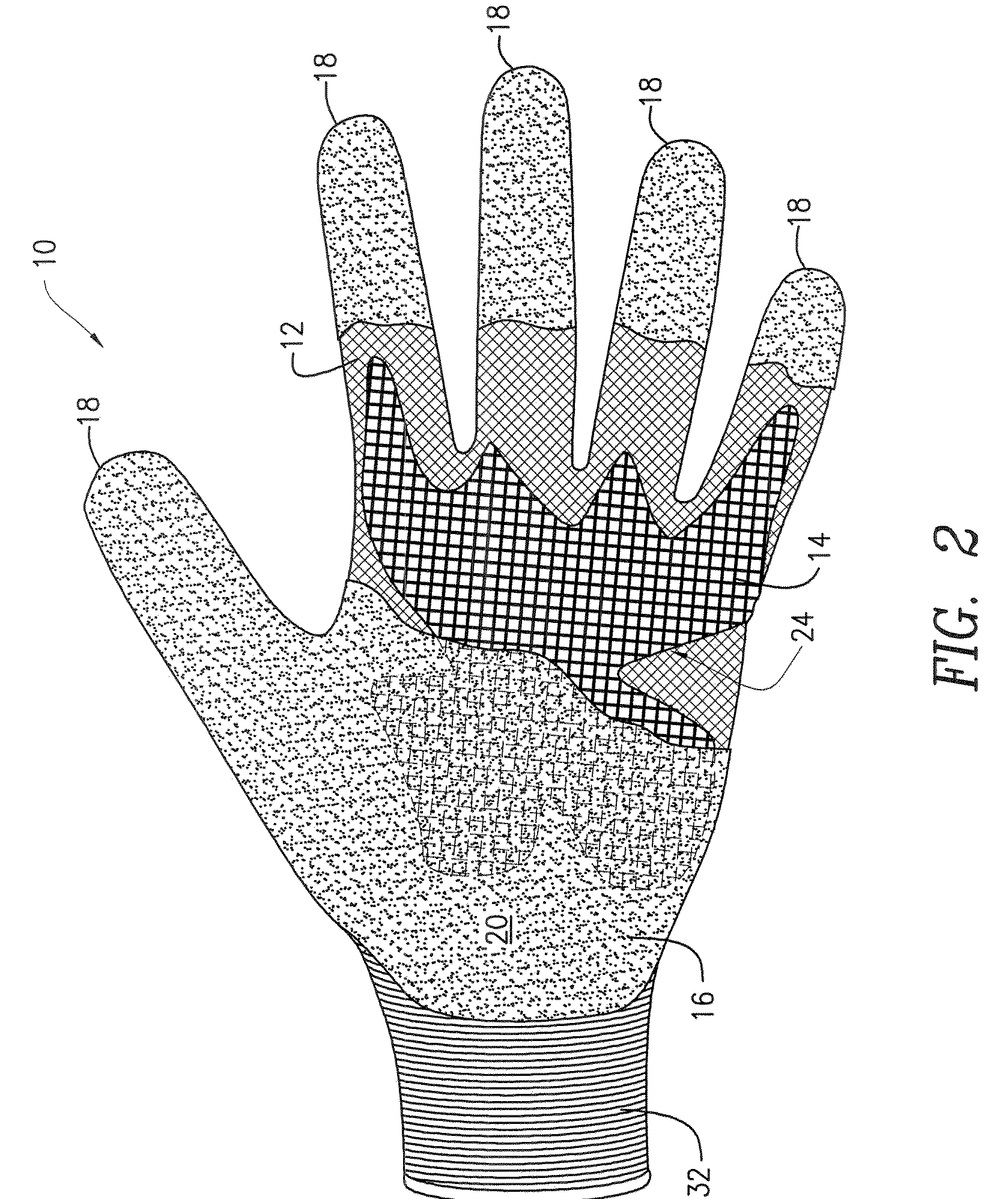

[0015]Referring to FIGS. 1-3 and 5, there is shown a glove 10 which includes a shell or substrate 12 (see FIG. 2), a reinforcing element 14 and a coating layer 16. The shell 12 is in the form of a conventional fabric glove and includes a plurality of finger portions 18, a palm side 20 and a back side 22. More particularly, the shell 12 can have a string-knit construction which provides a seamless shell, or a sewn-knit construction which provides a shell having seams. Alternatively, the shell 12 can be woven, knitted, or non-woven, including but not limited to bonded fiber, stitched bonded, needle punched, spun bonded and spun lace are examples of textile types which can be used.

[0016]The shell 12, especially if it has a knit construction, may also include areas or portions (not shown) that have a gauge (i.e., number of courses of threads per inch) or strength or size different from the rest of the shell 12, thereby providing integrally formed reinforcing portions with different text...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap