Shelving system

a technology of shelving system and shelving plate, which is applied in the direction of sectional furniture, adjustable height tables, dismountable cabinets, etc., can solve the problem of user performing complicated assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

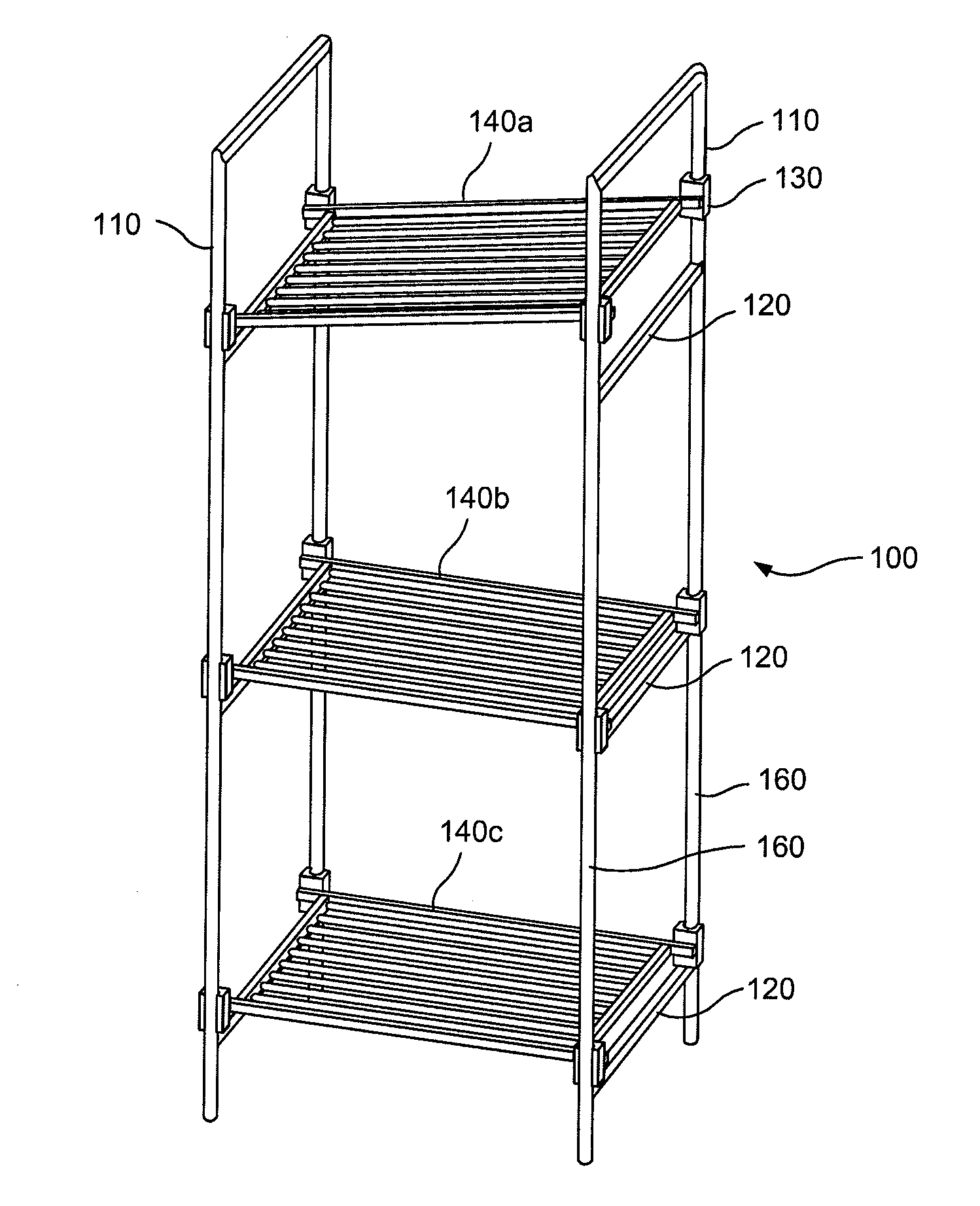

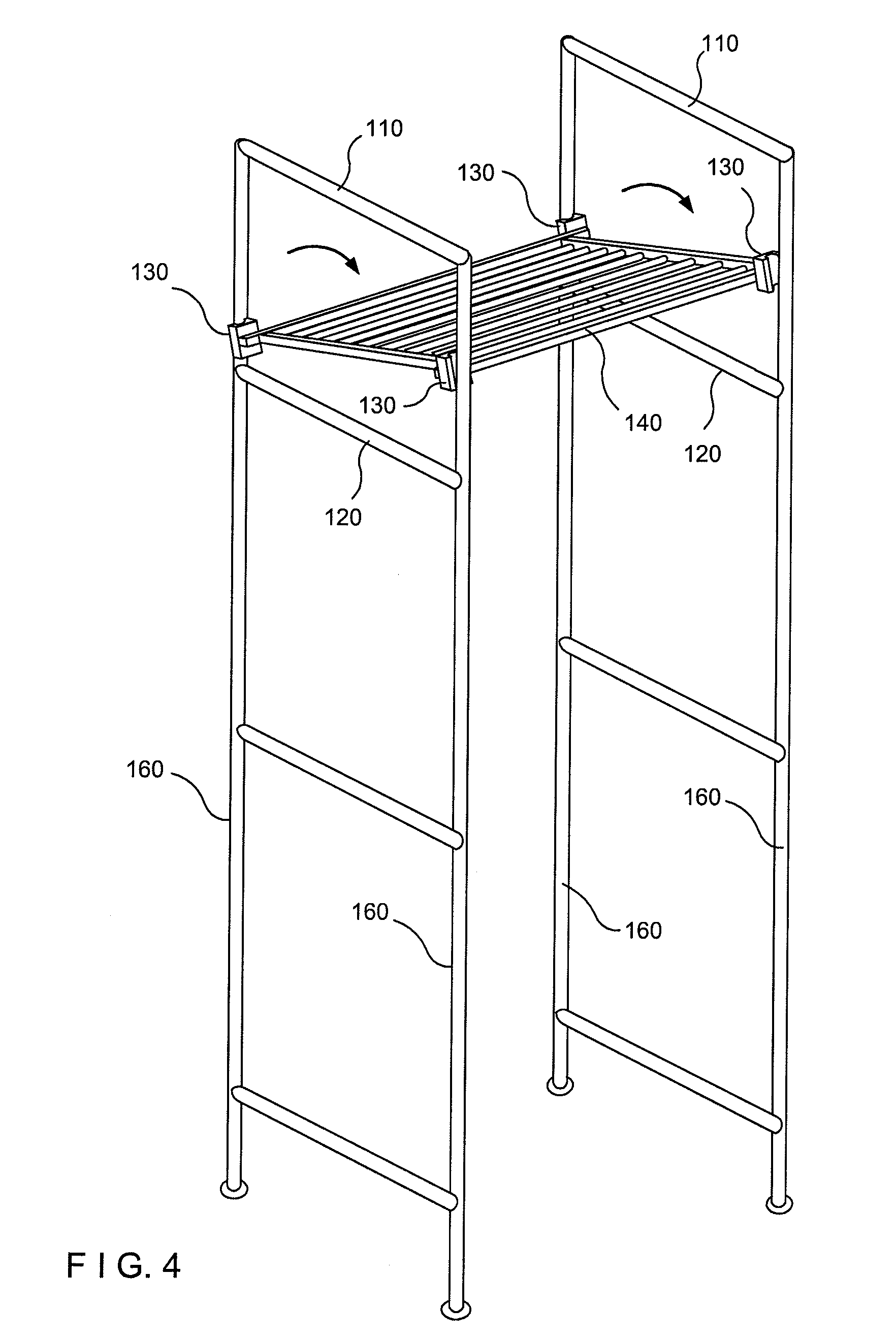

[0016]FIG. 1 illustrates a shelving unit 100 according to the present disclosure. The shelving unit can have two vertical frames 110. Vertical frames 110 can include at least two vertical posts 160 that are separated by shelf supports 120. Shelf supports 120 may be substantially horizontal, that is, perpendicular to vertical posts 110.

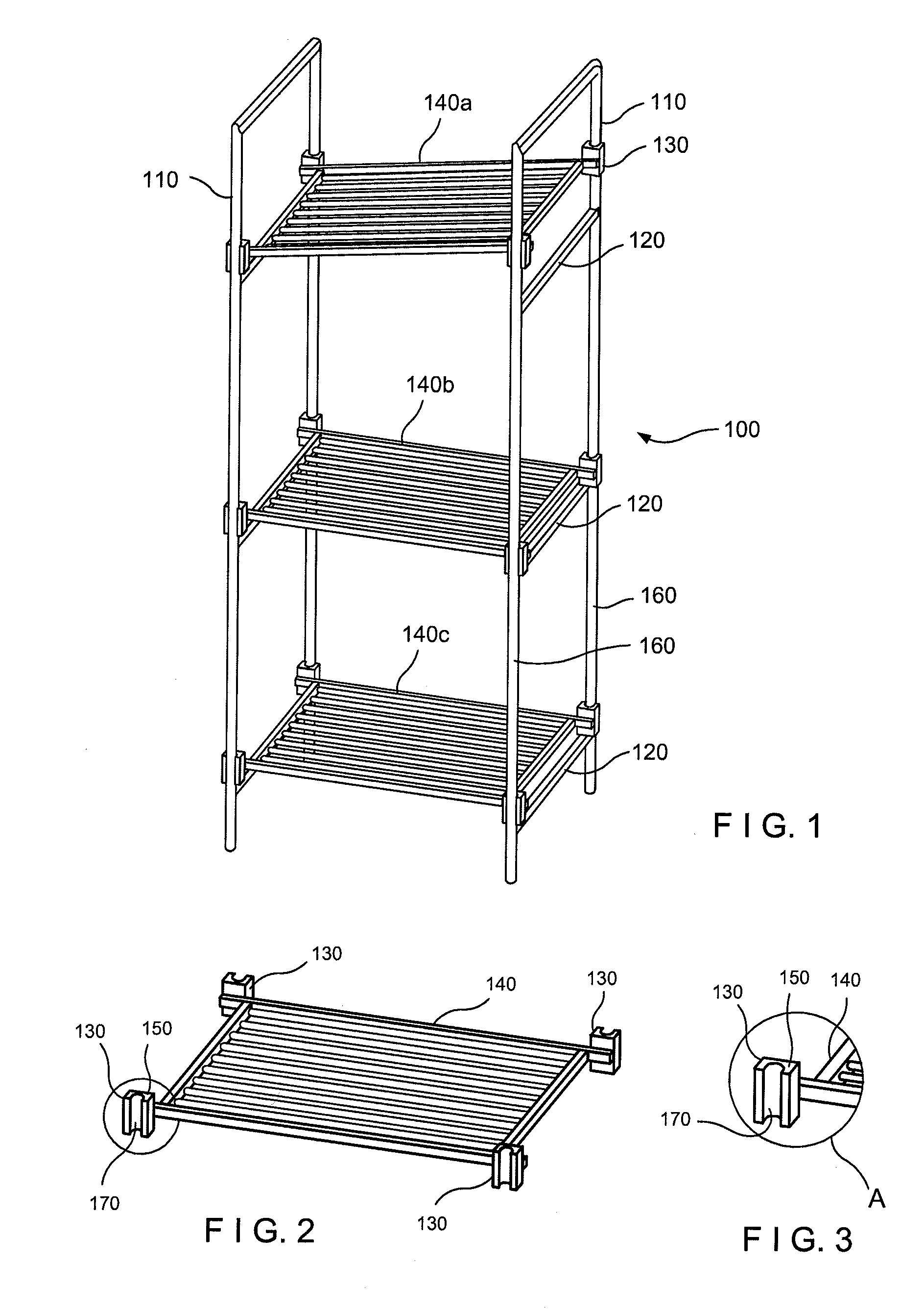

[0017]Shelf 140 is mounted between two vertical frames 110 using sliding mounting connectors 130 located on the periphery of the shelf. In one embodiment, the shelf 140 is a polygonal shape although the shape of the shelf can be curved or a combination of curved and straight edges. In a particular embodiment, the shelf is rectangular and the sliding mounting connectors are mounted on the shelf substantially at the corners of the shelf. Sliding mounting connectors 130 have U-shaped channels, as described below, and engage vertical post 160 of the vertical frame 110 substantially at the corners of the shelf 140.

[0018]Sliding mounting connectors 130 of a ...

second embodiment

[0025]FIG. 7 illustrates a shelving system including a shelving unit 700 that is expanded sideways. The expansion includes an additional vertical frame 710b, shelves 740b and sliding mounting connectors 730b.

[0026]Shelving unit 700 is assembled substantially as described in FIG. 1. That is, in summary, shelf 740 is assembled to vertical posts 760 of vertical frame 710a by sliding mounting connectors 730. Shelf 740 can slide along vertical posts 760 until sliding mounting connector 730 comes in contact with shelf support 720 and is supported thereby. A wedge-shaped piece (not shown) can be wedged between sliding mounting connector 730 and vertical post 760b to prevent further sliding of shelf 740.

[0027]Shelving unit 700 can be expanded sideways by assembling an additional vertical frame 710b and shelf 740b to shelving unit 700. Shelf 740b has sliding mounting connectors 730b on the periphery of the shelf 740b. In an embodiment where shelf 740b is rectangular, sliding mounting connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| rectangular shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com