Structure of a mesh supporting frame of a mesh chair and assembly of the mesh chair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

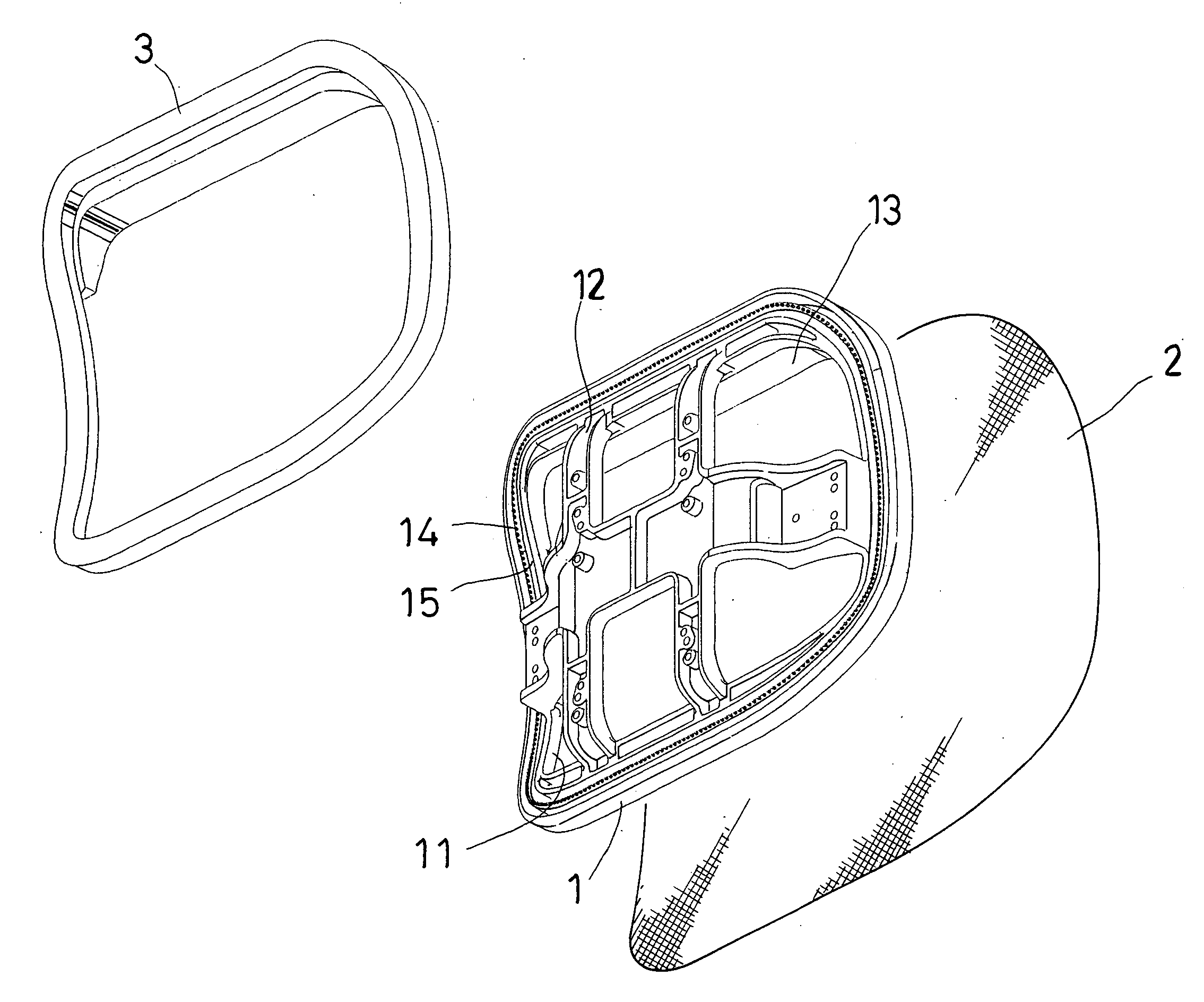

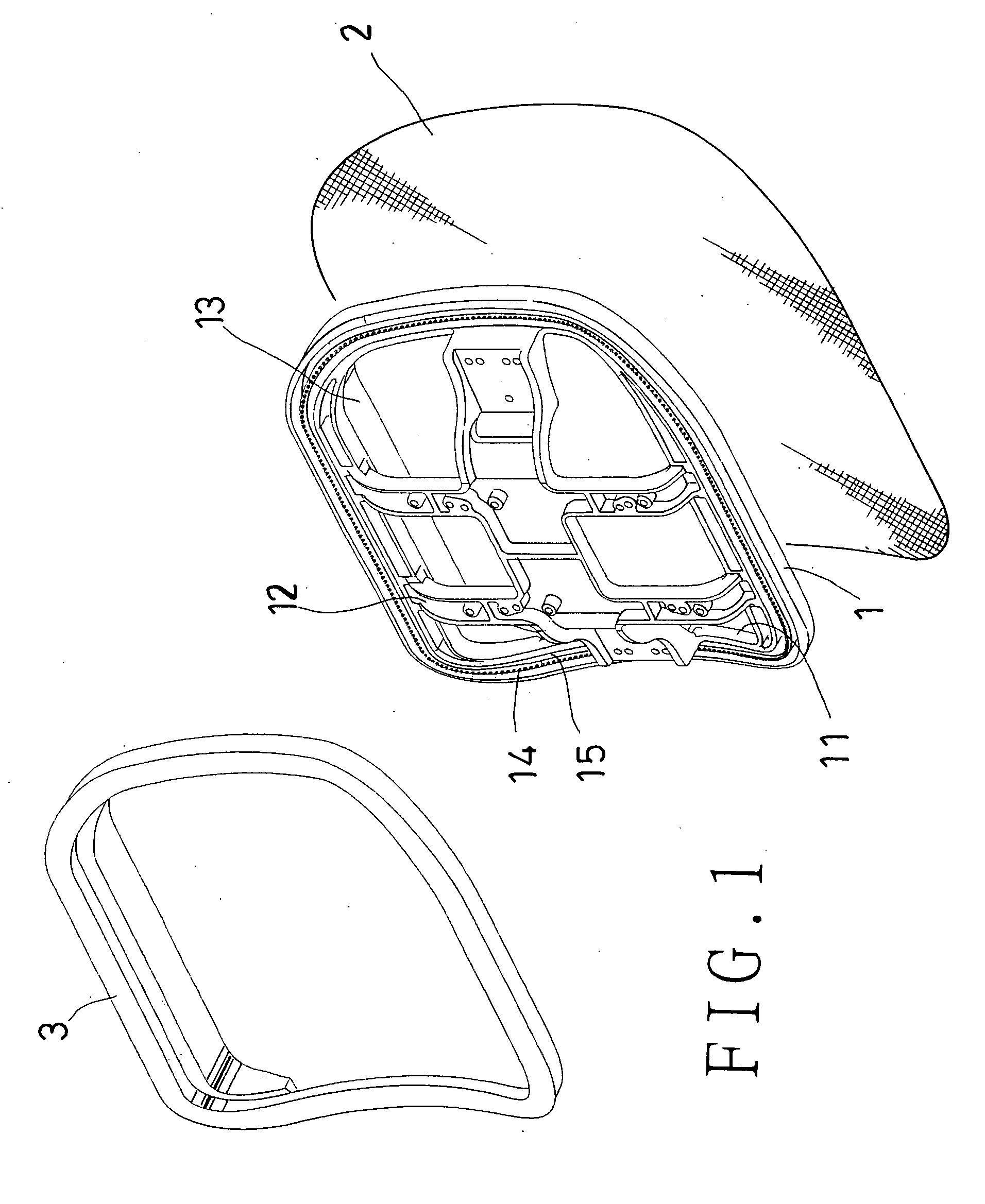

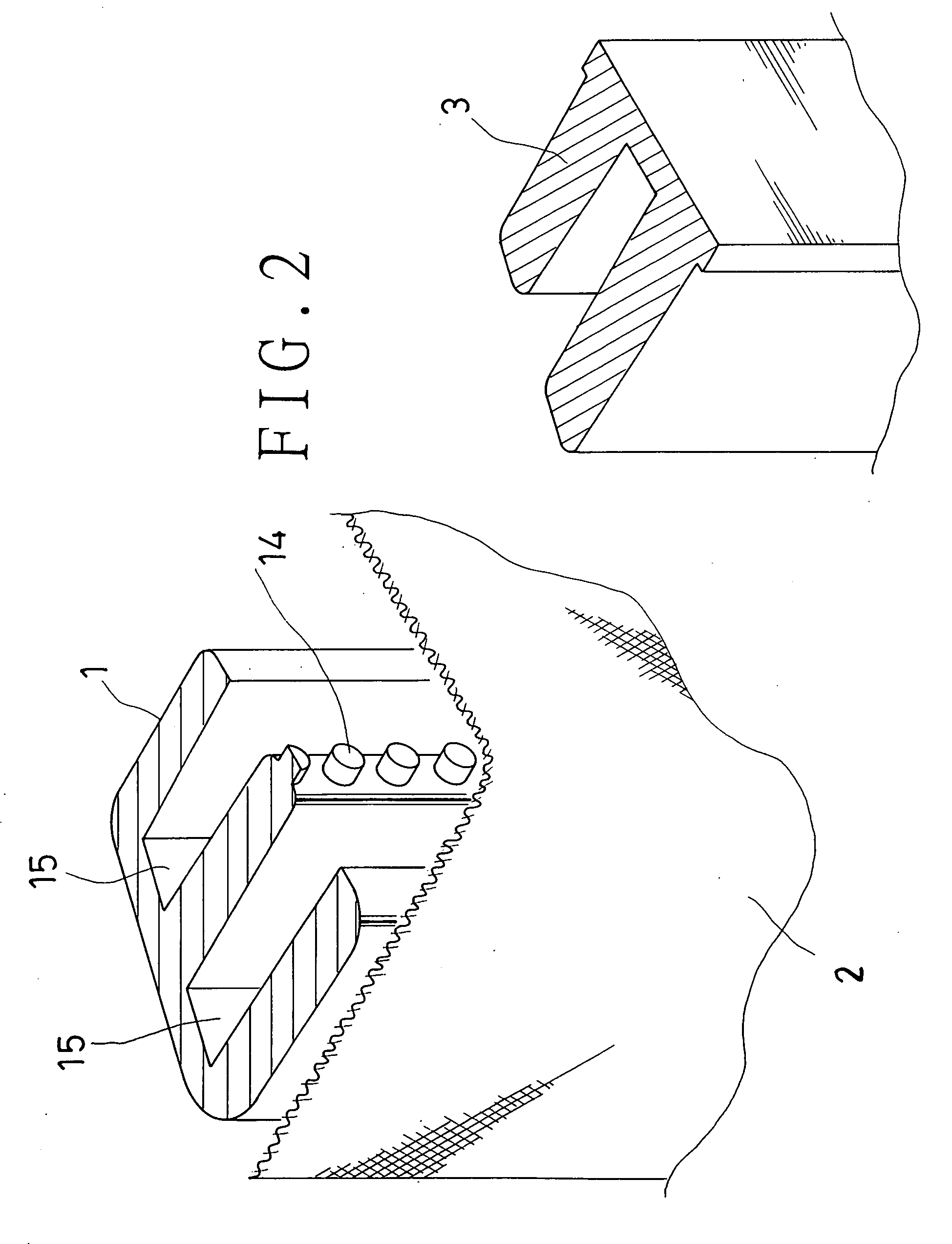

[0025]Referring to FIGS. 1 and 2, an assembly of a mesh chair in accordance with the present invention is illustrated. The mesh chair includes a mesh supporting frame 1, and a mesh 2 positioned over and joined on the mesh supporting frame 1; in assembly, first the mesh 2 is joined on the mesh supporting frame 1, and next injection molding is carried out to form a wrapping layer 3 over the joint between the mesh 2 and the mesh supporting frame 1.

[0026]The mesh supporting frame 1 has a hollow portion 11 on a middle thereof, and several supporting ribs 12 joined thereon, which extend across the middle hollow portion 11. The supporting ribs 12 bend rearwardly of the mesh supporting frame 1; thus, a recessed portion 13 exists in front of the supporting ribs 12 on the front side of the mesh supporting frame 1.

[0027]In addition, the mesh supporting frame 1 has several joining post portions 14 spaced apart around the middle hollow portion 11 on a rear side thereof; the joining post portions...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap