Underground mine ventilation curtain or barrier

a ventilation curtain and mine technology, applied in the direction of props/chocks, earthwork drilling and mining, mining structures, etc., can solve the problems of air leakage above and below the curtain, large amount of waste of air cooling them unnecessarily,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

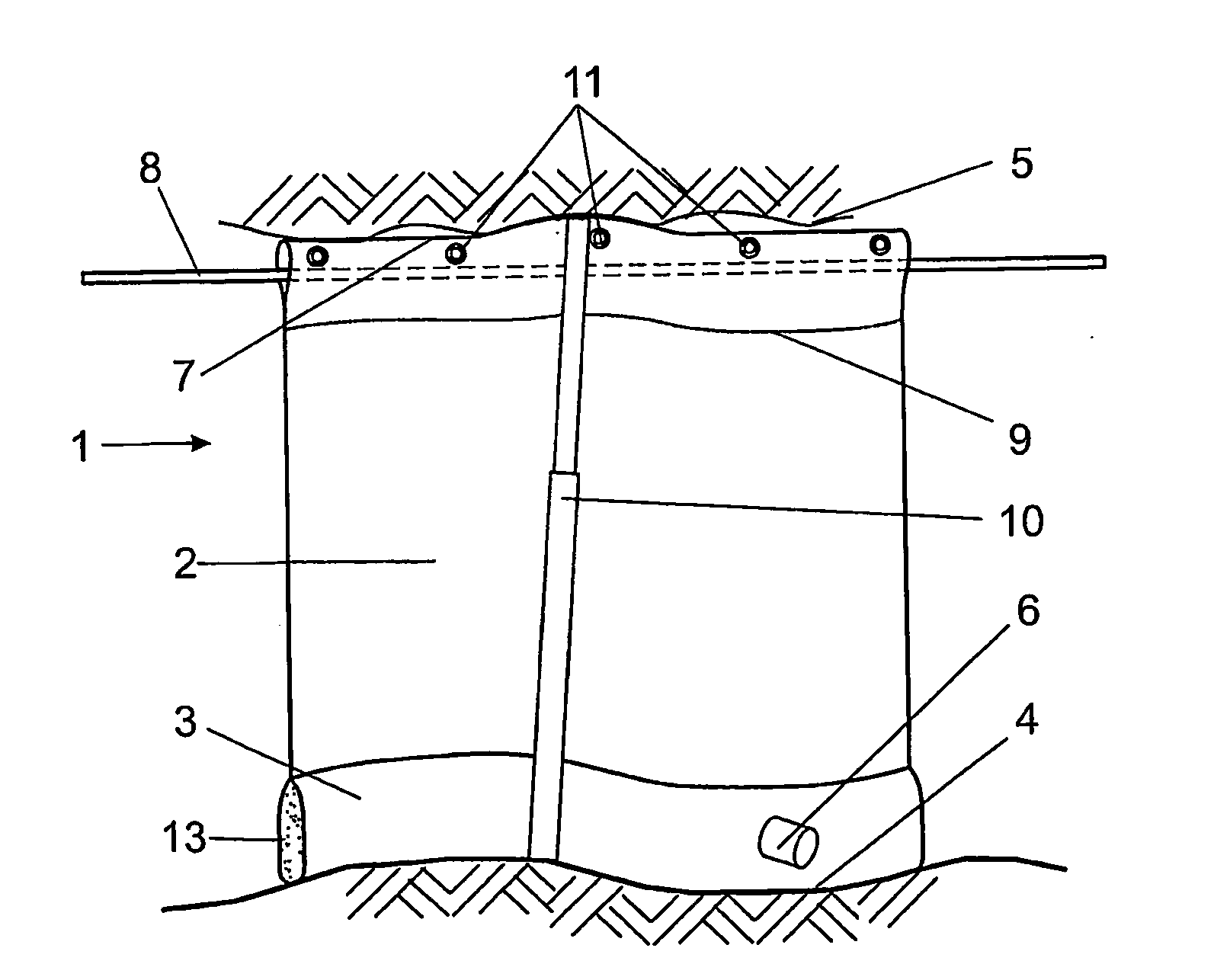

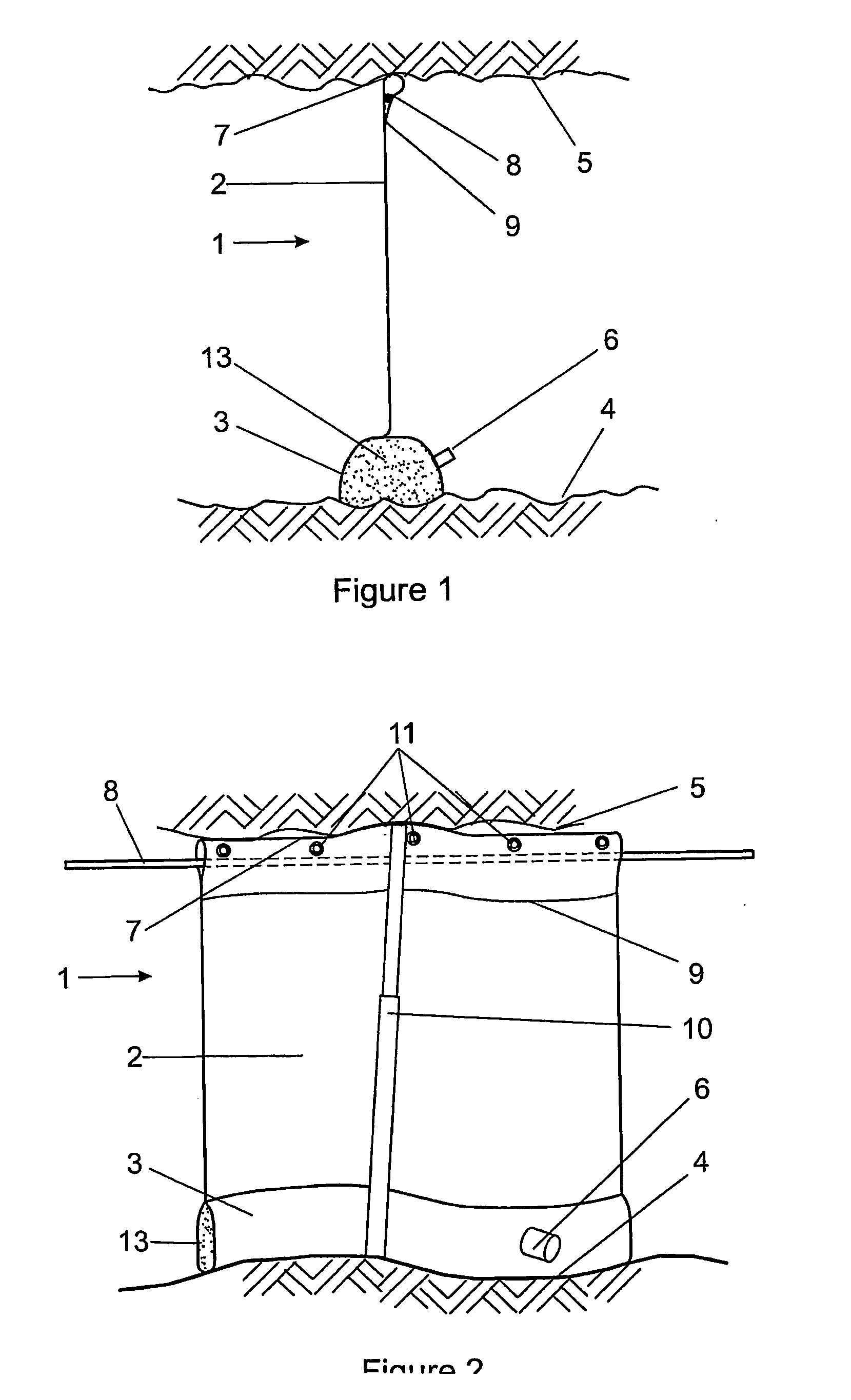

[0023]In the embodiment of the first variation of the invention illustrated in FIGS. 1 to 3 a flexible mine ventilation curtain, generally indicated by numeral (1), comprises, in the operative condition, a generally upright curtain (2) extending from a foot wall compartment (3) that engages the footwall (4) in an underground mine to an overhanging hanging wall (5).

[0024]Both the curtain and footwall compartment are made of a water permeable flexible sheet material, typically a geotextile material or a suitable membrane, and the footwall compartment could be made by stitching the sheet material back upon itself to provide a suitable cross-sectional size of footwall compartment. The flexible sheet material is selected so that it allows water to pass through it whilst retaining solids such as a cementitious grout or backfill material within the footwall compartment. The footwall compartment has a nonreturn inlet valve (6) for the introduction of slurry into the compartment.

[0025]The ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com