Tailgating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

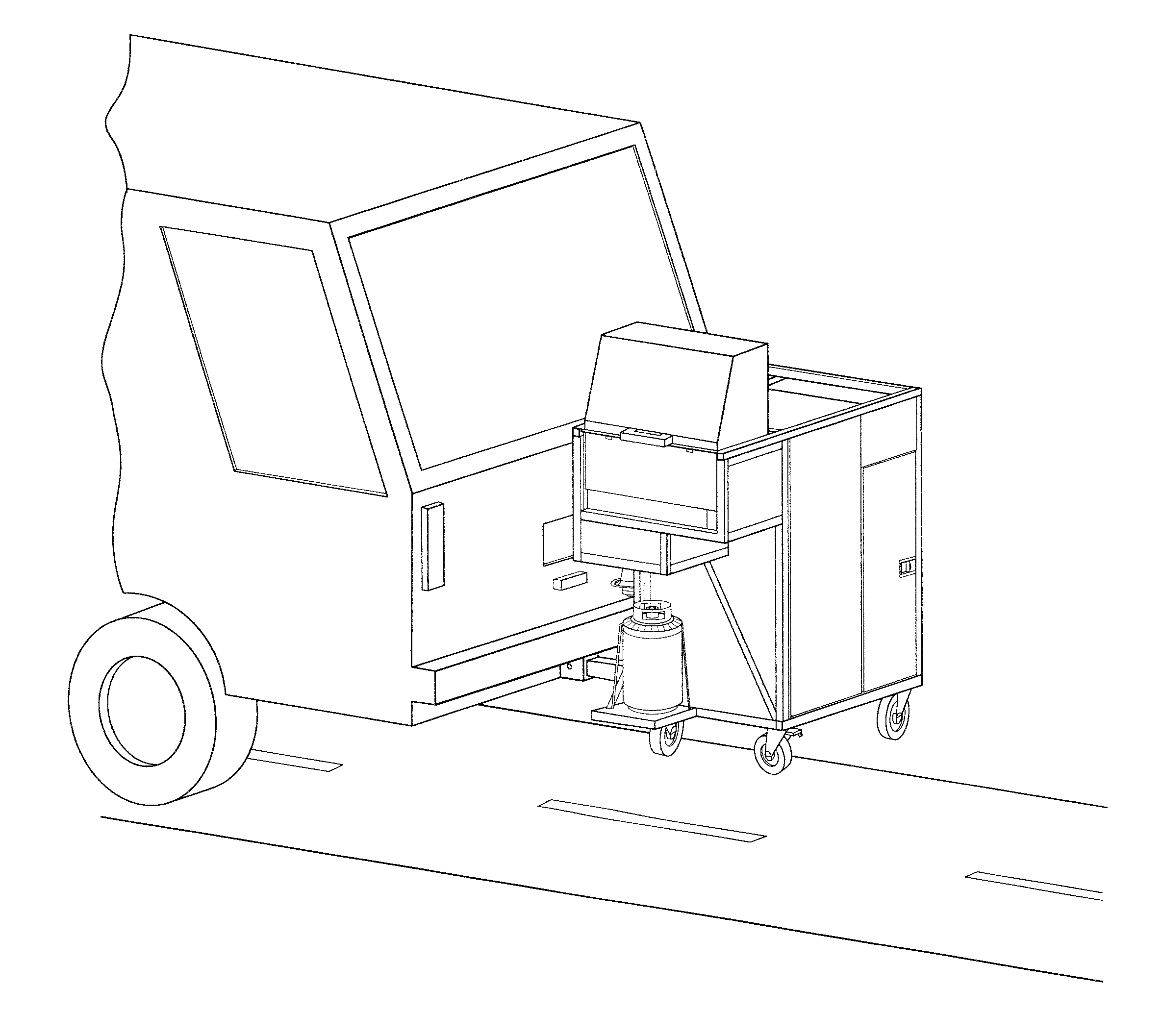

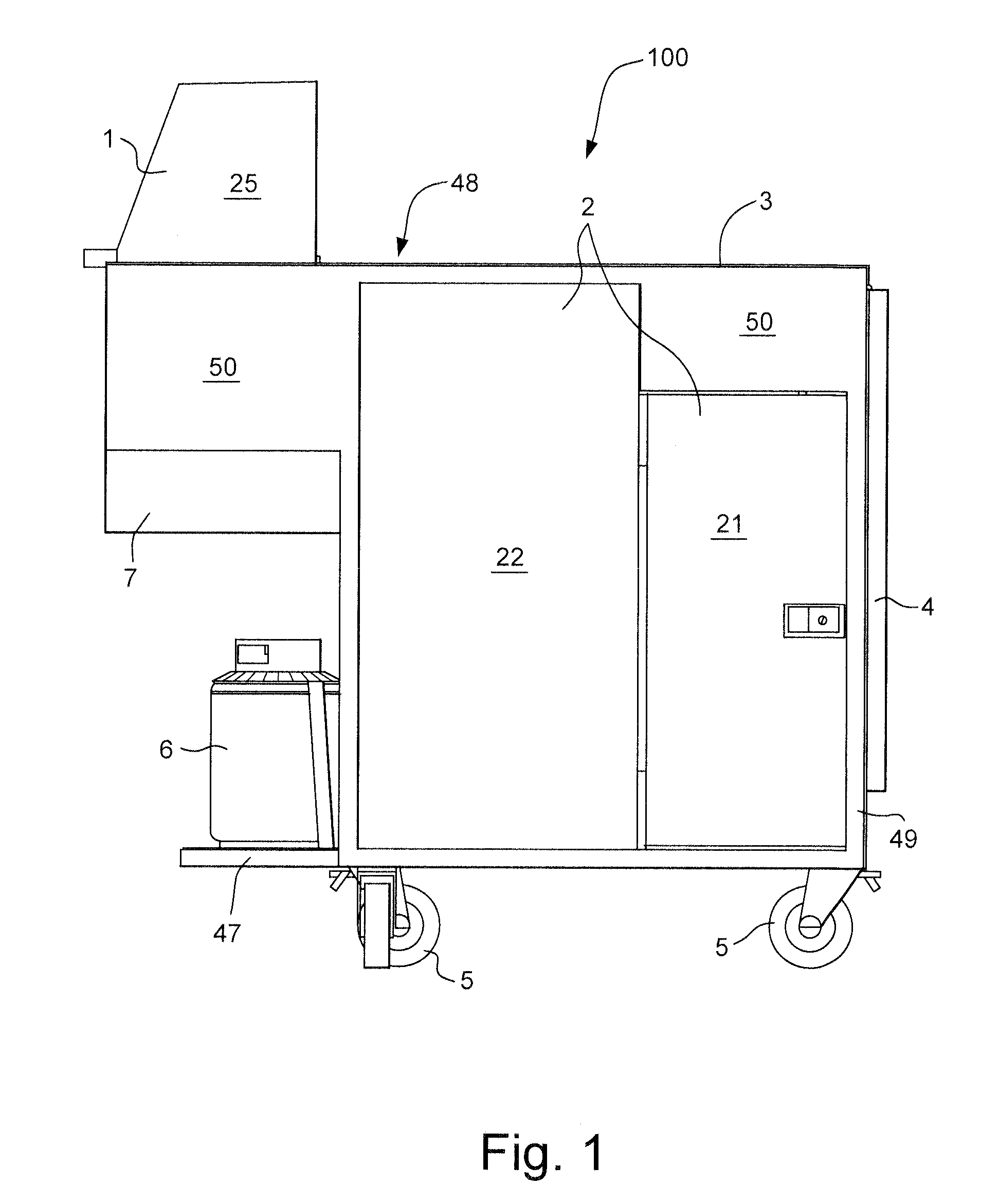

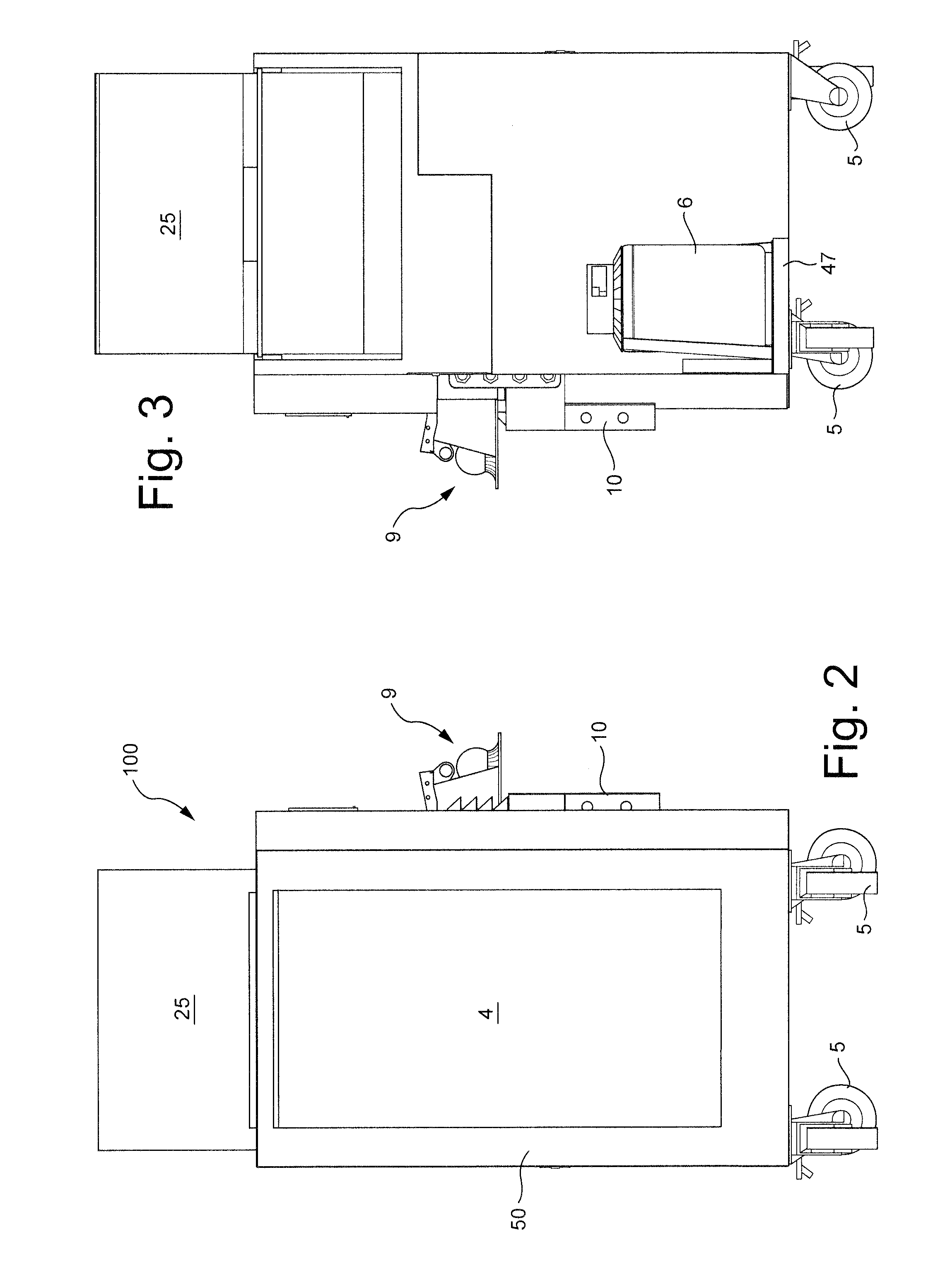

[0108]Referring to FIGS. 1-7, the tailgating system 100 may be composed of a frame 48 constructed from square tube 49 formed of, for example, aluminum. Panels 50 formed of, for example aluminum, may be used to make the exterior surfaces of the tailgating system 100.

[0109]The tailgating system 100 may comprise a grill 1, a refrigerator 2, a countertop 3, a side table 4, pneumatic castor wheels 5 for mobility, a gas (e.g. propane) tank 6 to supply the grill, a dry storage space 7, and a utility cabinet 8 to store the tailgating system's components. The tailgating system may use a motorized hitch assembly 9 to lift and lower the tailgating system from a vehicle hitch, and a securing sleeve 10 to prevent movement during travel.

[0110]The grill 1 may be constructed from steel sheet metal. The grill 1 may be secured to the aluminum square tube frame 48 via sliding shelf rails 51. A gas tank mount 47 attached to the tailgating system allows gas tank 6 to be secured to the tailgating system....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com