Golf ball

a technology for golf balls and balls, applied in the field of golf balls, can solve the problems of poor control of balls, low rate, and inability to meet the needs of low-handicappers or professionals, and achieve the effect of improving the control of balls and improving the accuracy of balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

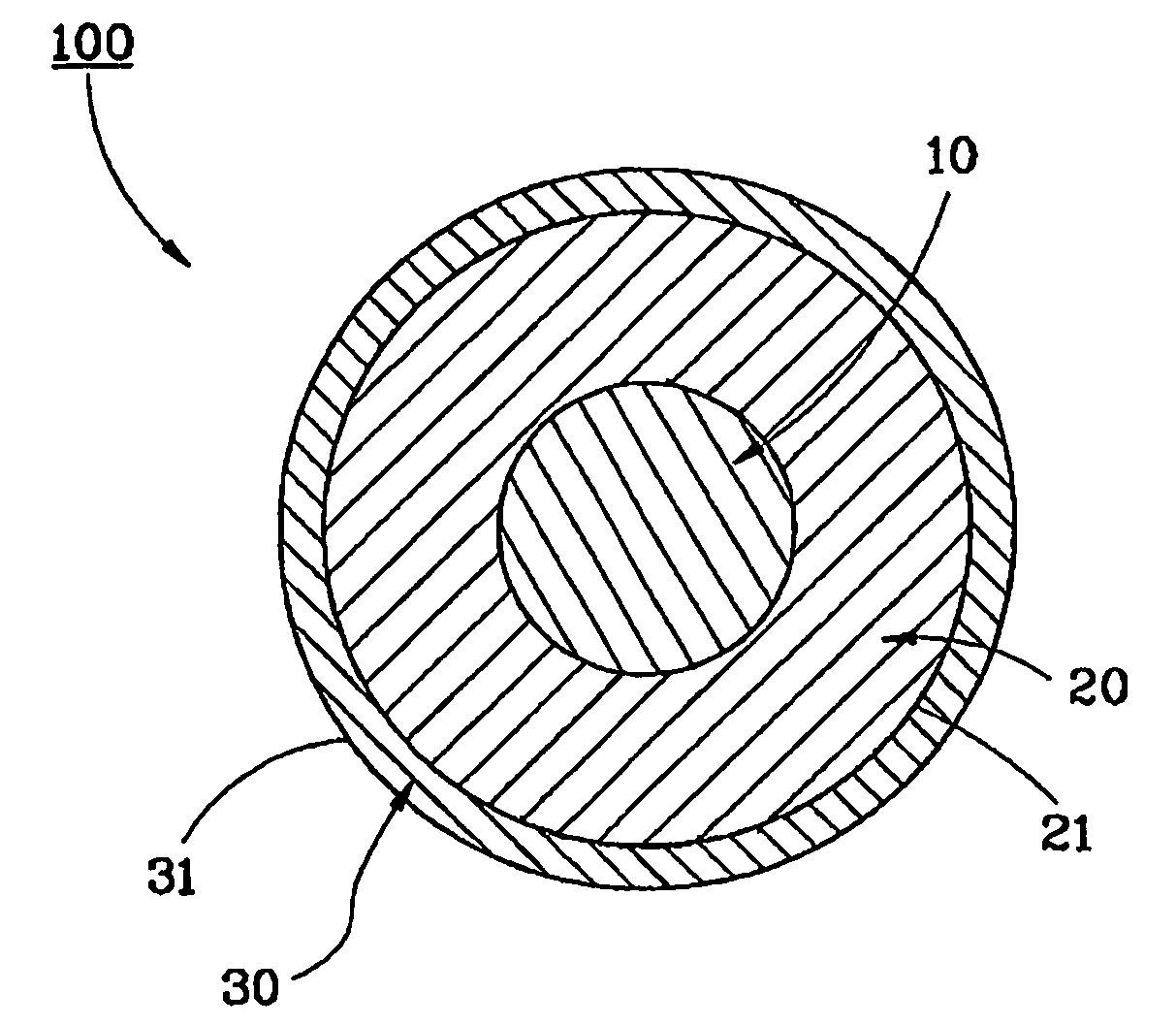

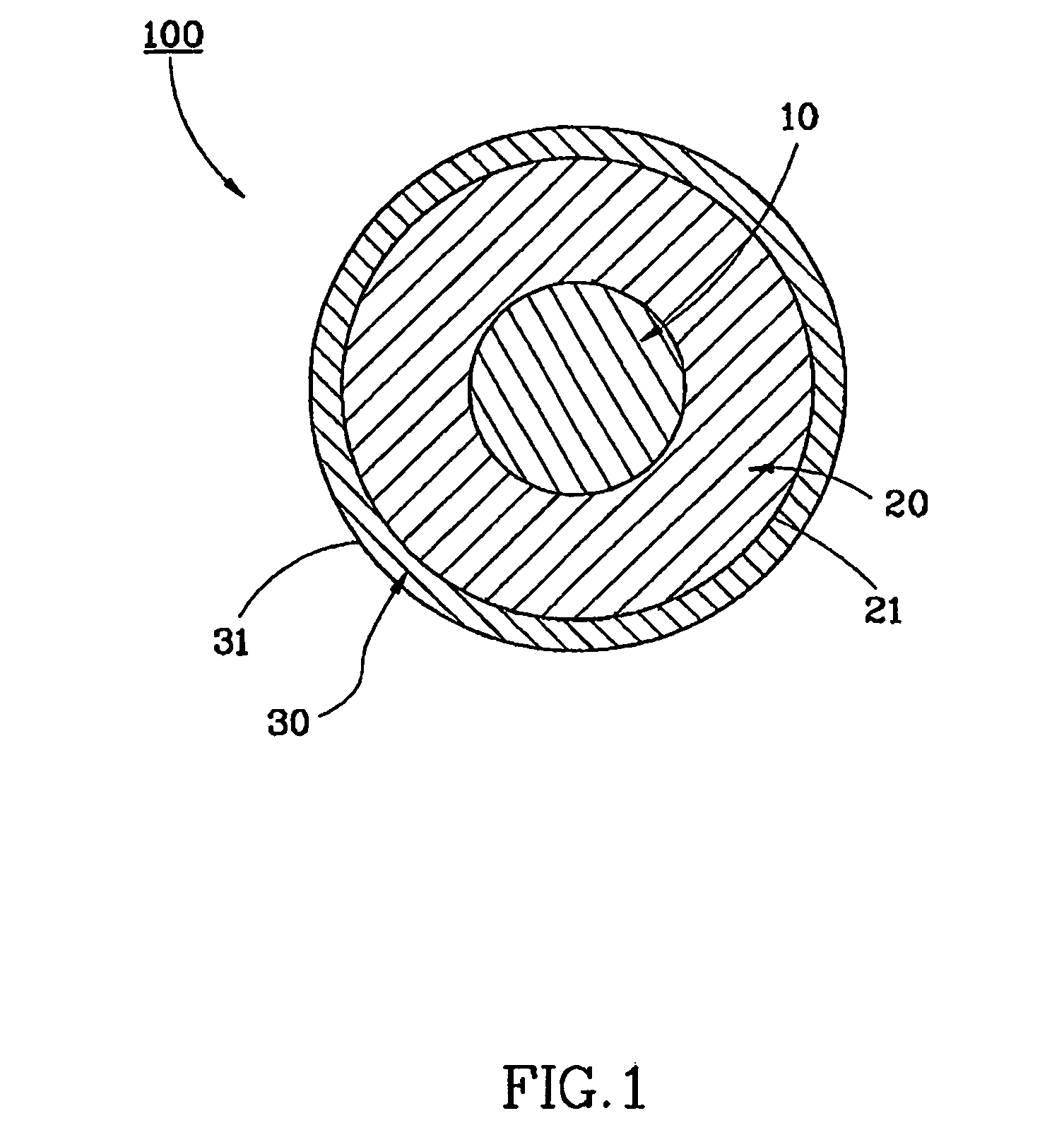

[0013]Referring to FIG. 1, a golf ball 100 constructed according to a preferred embodiment comprises a core 10, an intermediate layer 20, and a cover layer 30.

[0014]The core 10 is made from a thermoplastic material selected from a group consisting of ionomer resin, polyamide resin, polyester resin, polyurethane resin, and a mixture thereof. In this embodiment, ionomer resin is preferred for the core 10. The suitable ionomer resin includes HPF and Surlyn®, both commercially available from E.I. DuPont de Nemours and Company, or IOTEK®, commercially available from Exxon Corporation.

[0015]To increase the COR of the core 10 for longer flight distance, the core 10 is made from a primary material, like HPF 1000 or HPF 2000, and from an optional secondary material, like Surlyn® or IOTEK®. The secondary material of the core 10 is in an amount of 0 to 10 parts by weight, based on 100 parts by weight of the primary material of the core 10.

[0016]It is to be noted that the COR of the core 10 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com