Artificial toe joint

a technology toe bones, applied in the field of artificial toe joints, can solve the problems that current joints generally cannot compensate for metatarsal length variations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The invention and accompanying drawings will now be discussed in reference to the numerals provided therein so as to enable one skilled in the art to practice the present invention. The drawings and descriptions are exemplary of various aspects of the invention and are not intended to narrow the scope of the appended claims.

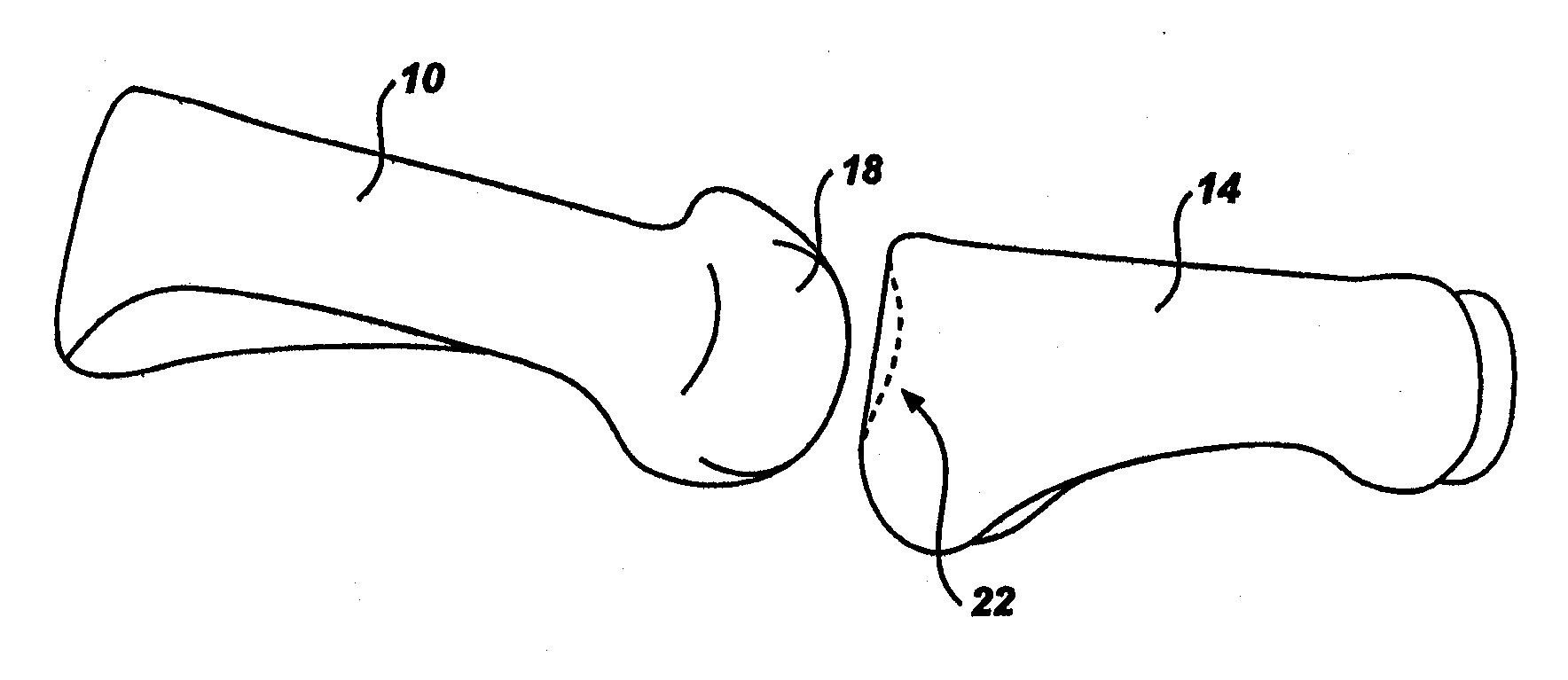

[0035]Turning now to FIG. 1, a perspective view of the bones of the proximal toe joint (the metatarsal phalangeal joint) is shown. The innermost toe joint (closest to the foot) is shown. The joint includes a metatarsal bone 10 and a phalange bone 14. The metatarsal bone 10 includes a rounded end 18 which, together with a depression 22 in the phalange bone 14 and the associated cartilage and tissue, forms the joint. The replacement of the toe joint may be necessitated by damage to the bones 10, 14 or to the cartilage and tissues of the joint. (While described in context of the first metatarsal phalangeal joint, the same anatomical presentations exist through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| perimeter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| durability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com