Heat exchanger

a heat exchanger and heat exchange technology, applied in the field of heat exchangers, can solve the problems of reducing the heat exchange efficiency of conventional heat exchangers, unable to meet current commercial demands, and relatively low heat exchange efficiency of heat exchangers using gas to disperse hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples 1 to 7

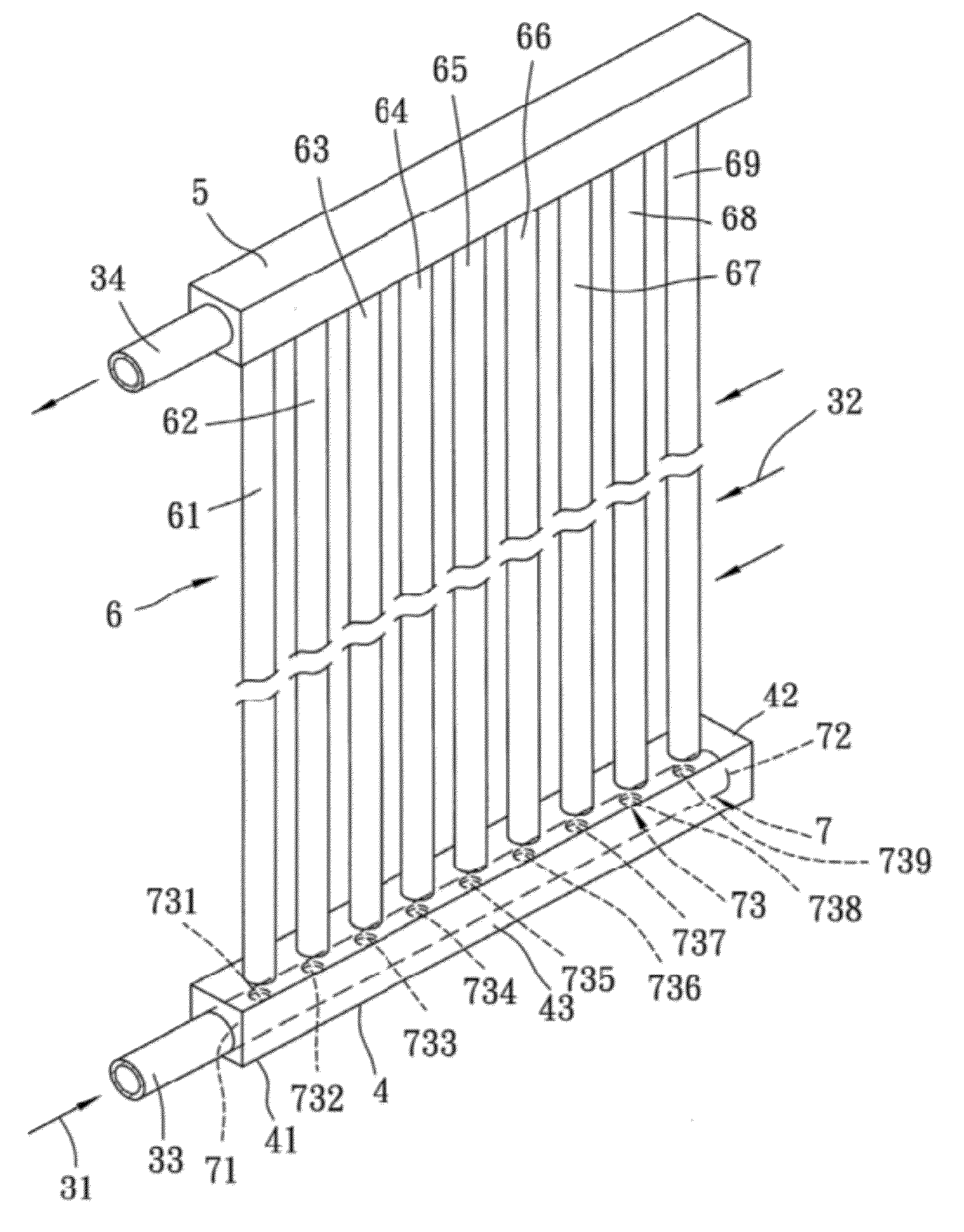

[0038]The heat exchanger of the present invention used in Examples 1 to 7 has a U-type structure as shown in FIG. 5, in which the inlet and outlet header tubes 4, 5 respectively have a square cross section with a width of 9 mm, each of the heat exchange tubes 6 has a circular cross section with an inner diameter of 3 mm, the baffle tube 7 has a circular cross section with an outer diameter of 6 mm and an inner diameter of 4 mm, and each of the orifices 73 of the baffle tube 7 has a circular shape. A distance of the connecting end 60 of the first heat exchange tube 61 from the first end 41 of the inlet header tube A is 3.5 mm, a center-to-center distance between two adjacent orifices 73 is 10 mm, and a center-to-center distance between two adjacent heat exchange tubes 6 is 10 mm. It should be noted that the inflow tube 31 has the same cross section as that of the baffle tube 7 in Examples 1 to 7. The first fluid 31 is water having a temperature of 25° C.

[0039]In Examples 1 to 7, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com