Fluid Holder And Electromechanical Lubricator Employing Same

a technology of electromechanical lubricator and fluid holder, which is applied in the direction of engine lubrication, lubricating pumps, engine components, etc., can solve the problems of increasing friction in the drive assembly, accelerating wear of the drive assembly, and thrusting force along the threaded member against the drive assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

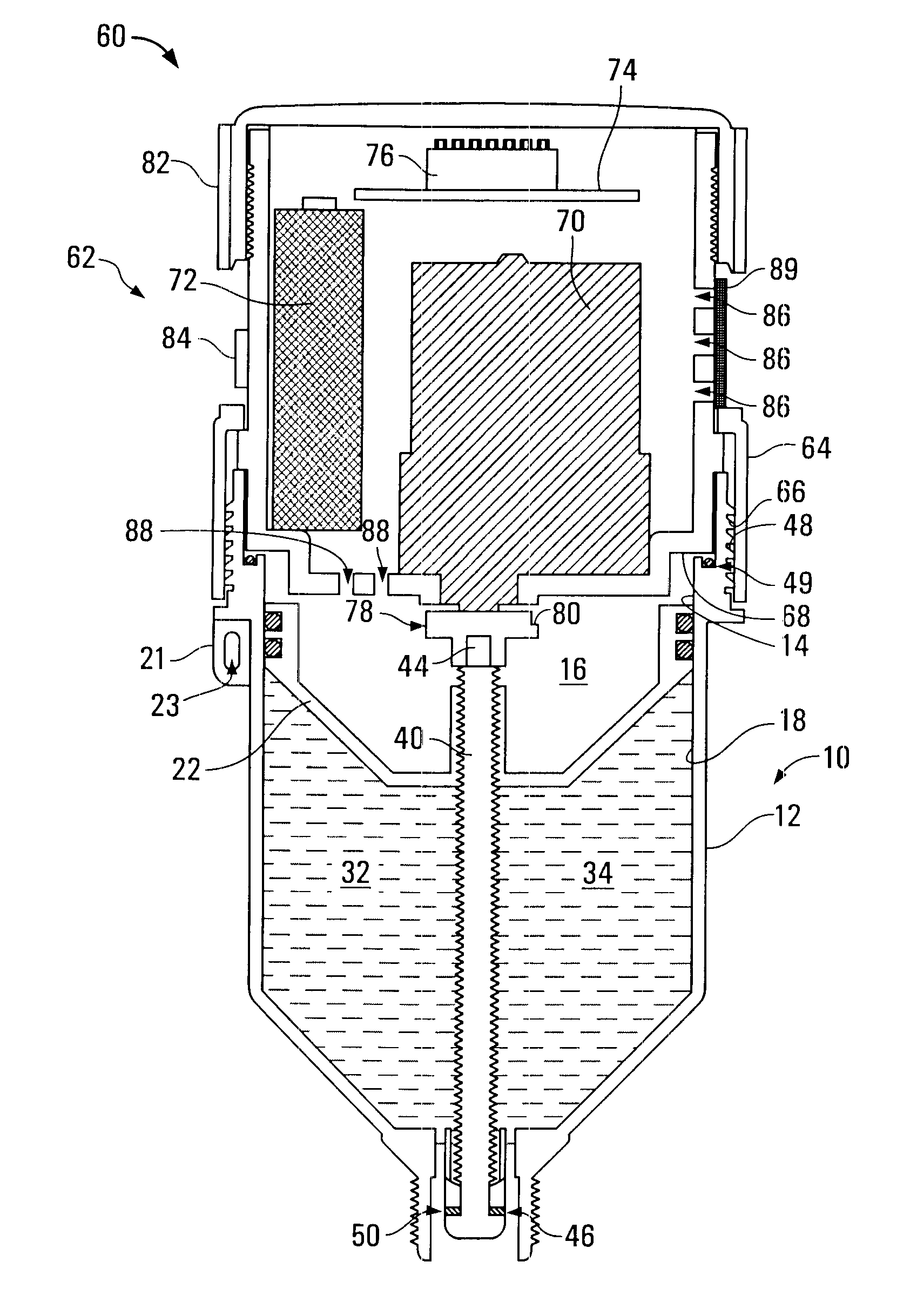

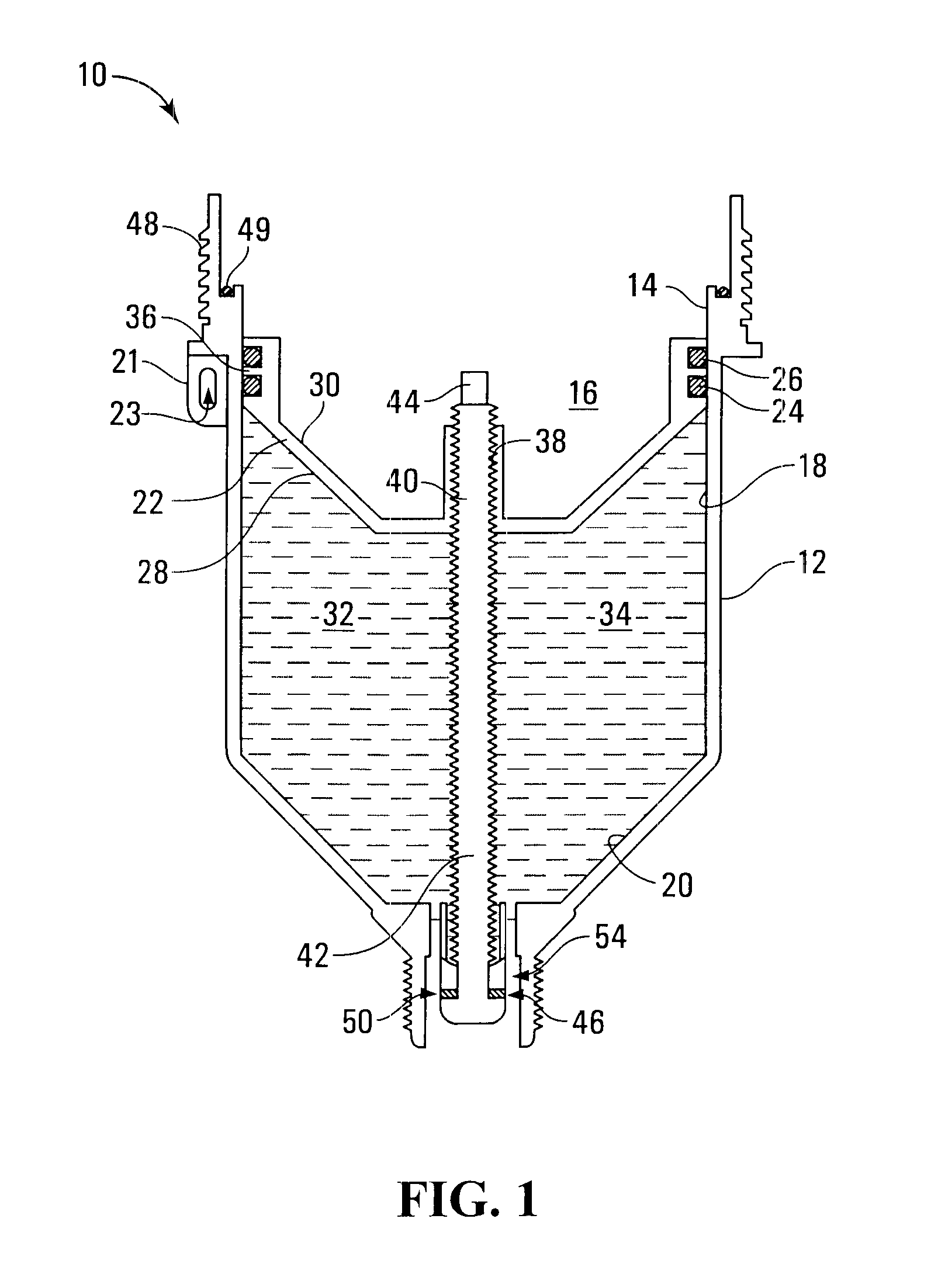

[0027]Referring to FIG. 1, a fluid holder according to the invention is shown generally at 10. The fluid holder 10 includes a housing 12 having an inner surface 14 that defines a cavity 16. In the illustrated embodiment, the inner surface 14 includes a cylindrically shaped sliding portion 18 and a generally frustoconical terminating portion 20. Alternatively, the terminating portion of inner surface 14 may be conical, for example. Housing 12 preferably includes a tie-down 21 defining an eyelet 23, and the eyelet 23 may receive a cord to facilitate attaching fluid holder 10 to an object (not shown), for example. However, it will be appreciated that equivalent results can be achieved with other configurations of the housing 12.

[0028]A piston 22 is positioned in cavity 16 in slidable engagement with sliding portion 18 of the inner surface 14. Piston 22 preferably includes sealing members such as O-rings 24 and 26 to facilitate slidable and sealed engagement with the inner surface 14. P...

second embodiment

[0033]Referring to FIG. 3, a fluid holder according to the invention is shown generally at 90. Fluid holder 90 includes a housing 92 having an inner surface 94 that defines a cavity 96. In the illustrated embodiment, the inner surface 94 includes a cylindrically shaped sliding portion 98 and a frustoconically shaped terminating portion 100 that includes a generally flat surface 102. Housing 92 preferably includes a tie-down 91 defining an eyelet 93, and the eyelet 93 may receive a cord to facilitate attaching fluid holder 90 to an object (not shown), for example.

[0034]The fluid holder 90 further includes a piston 104 positioned in cavity 96 in slidable engagement with sliding portion 98 of inner surface 94. Piston 104 includes a first surface 106 and a second opposite surface 108, and is positioned in cavity 96 such that first surface 106 and inner surface 94 define a fluid chamber 110 in cavity 96 for holding a fluid such as a lubricant 112, for example. First surface 106 of piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com