Container sealing system

a sealing system and container technology, applied in the field of container sealing system, can solve the problems of low cost, inconsistent use, and inability to produce strong seals in quick engagement structures, and achieve the effects of convenient opening and closing, high sealing, and convenient opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

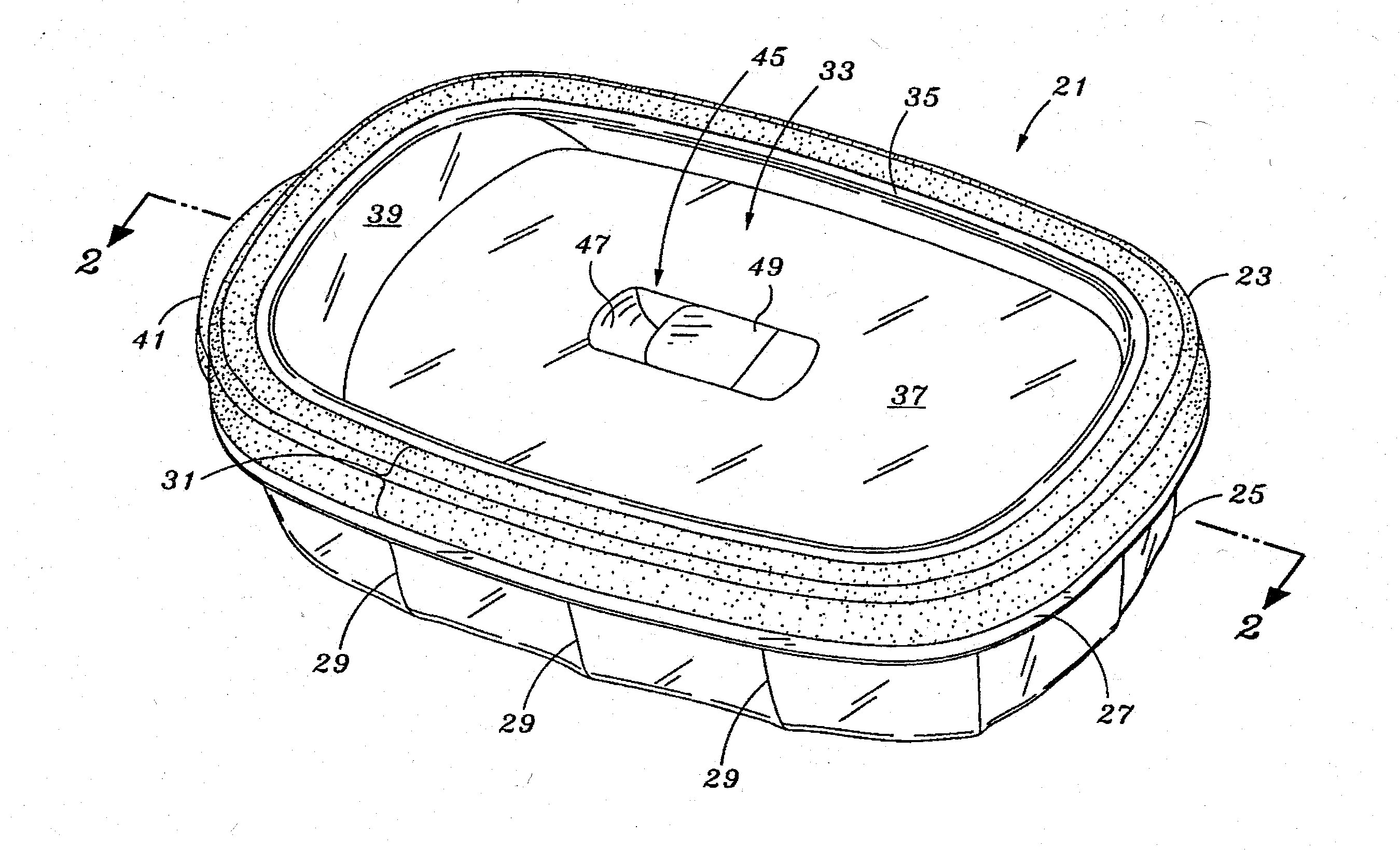

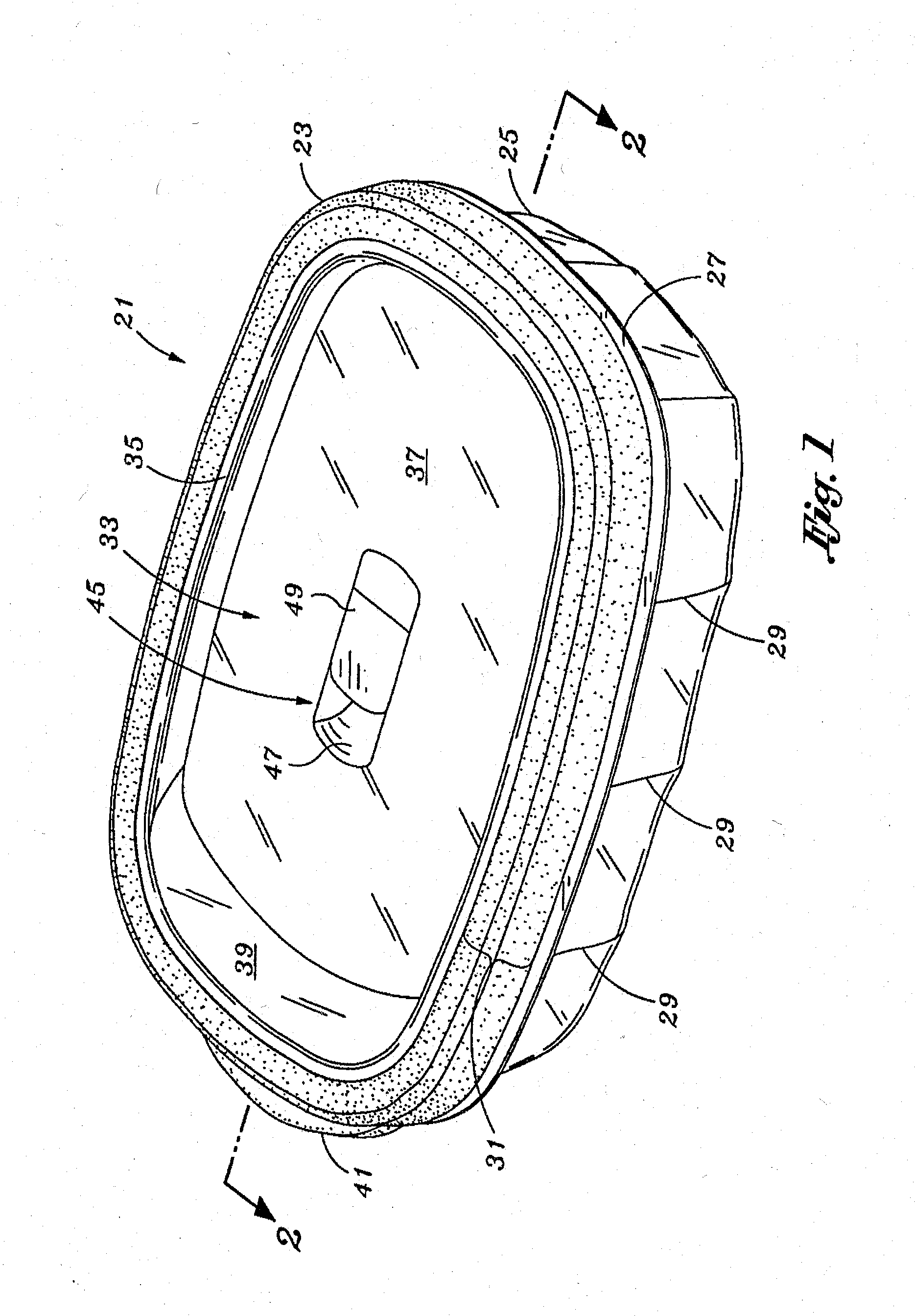

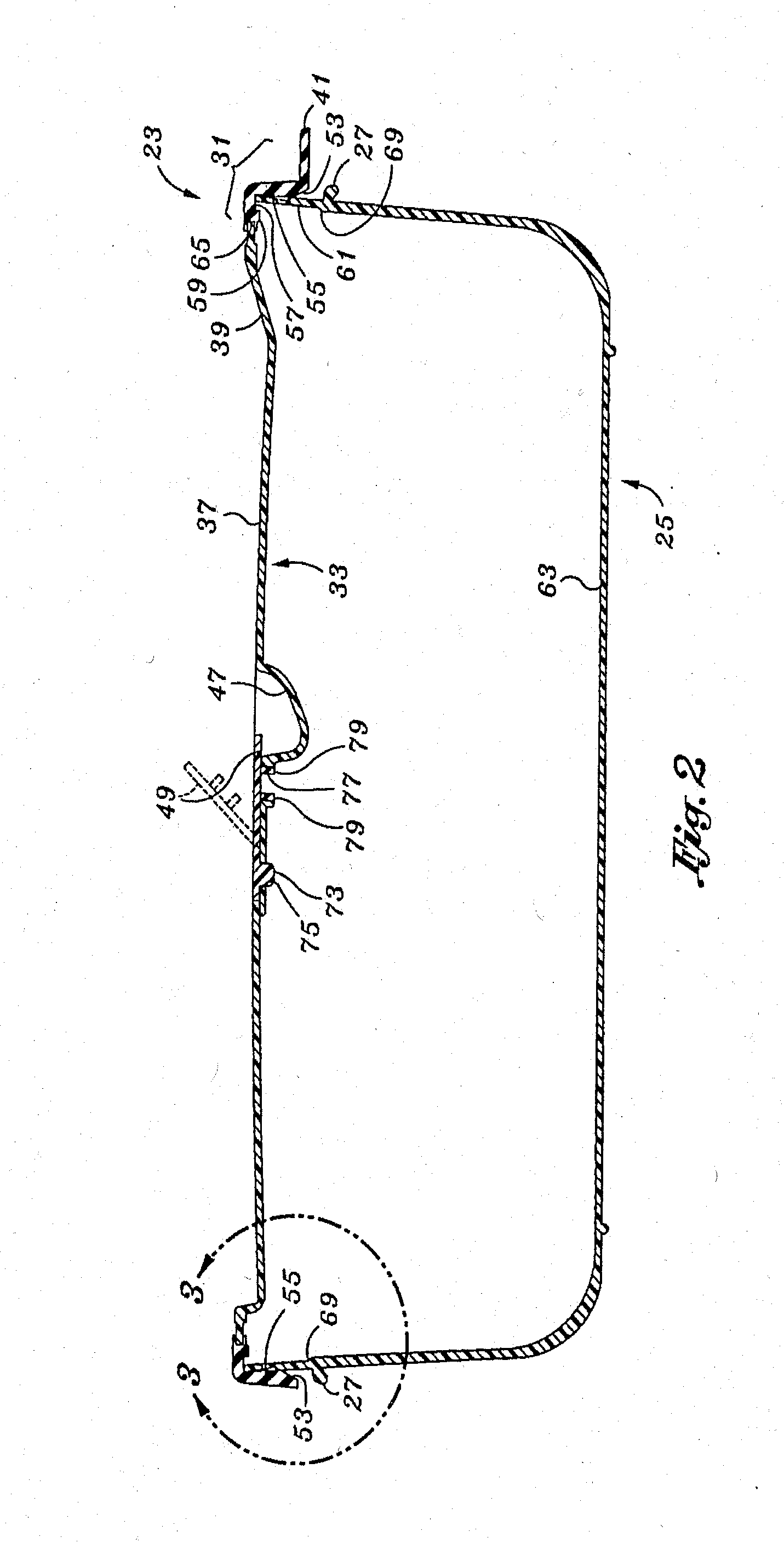

[0016]The description, construction and operation of the sealing system of the invention will be best illustrated by beginning with reference to FIG. 1, which illustrates a perspective view of a rectangular oblong container 21 including a lid 23 and a base container 25. The base container 25 may include a generally circumferentially outwardly projecting rim 27 which may serve as a reinforcement for the upper part of the base container 25 and as a visual indicator that the lid 23 is fitted in place, by visually exacerbating any displacement from a flat sealed condition. Also seen are a periodic series of vertical reinforcements 29 which project slightly outwardly from the generally vertical extent of the base container 25.

[0017]The lid 23 has a number of features. Lid 23 includes a flange portion 31 made of a more flexible material. Flange portion 31 is continuous adjacent the periphery of the lid 23. Into the flange portion 31, a harder plastic portion 33 is fitted and sealed. Seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com