Packaging cushioning structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

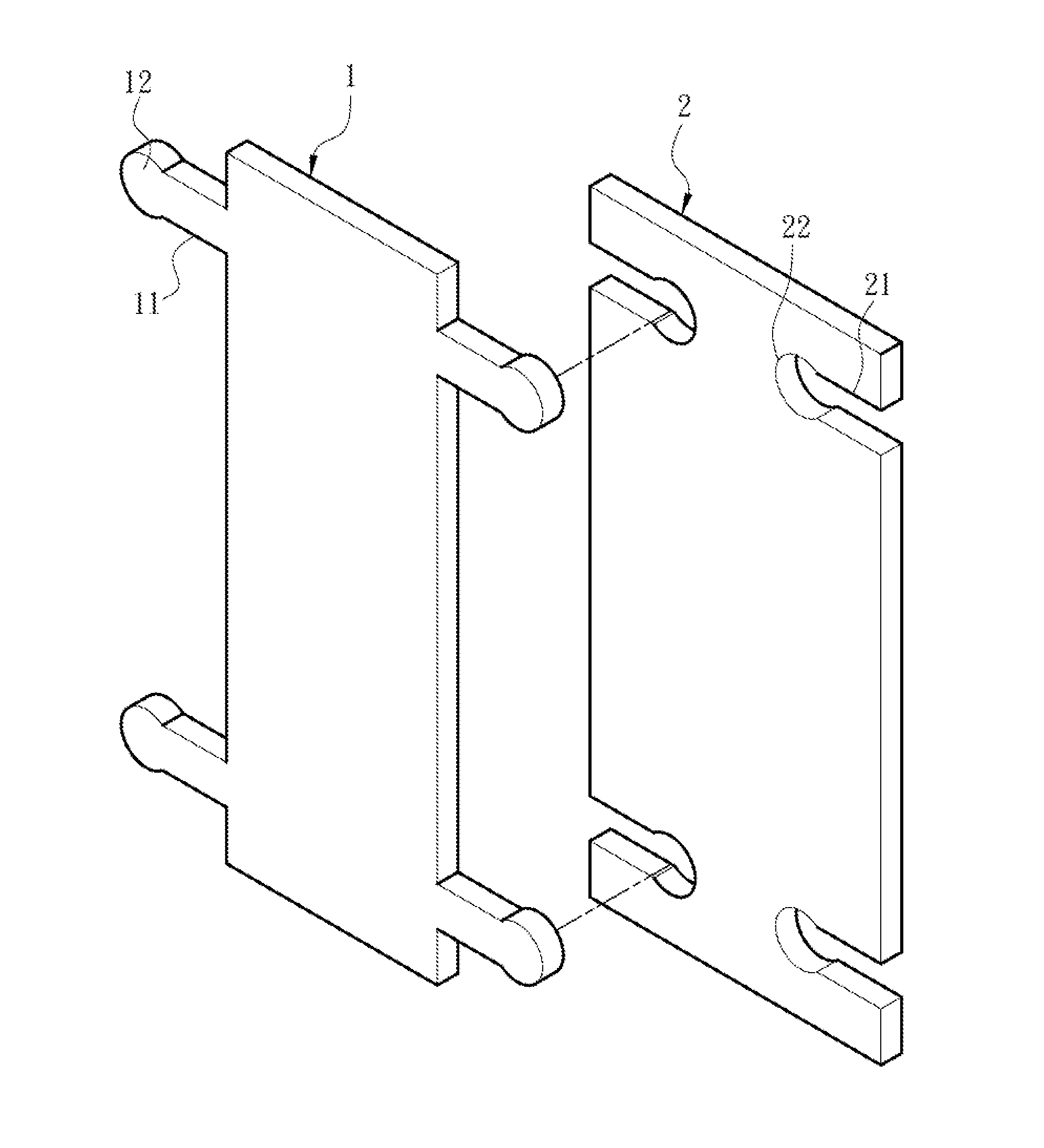

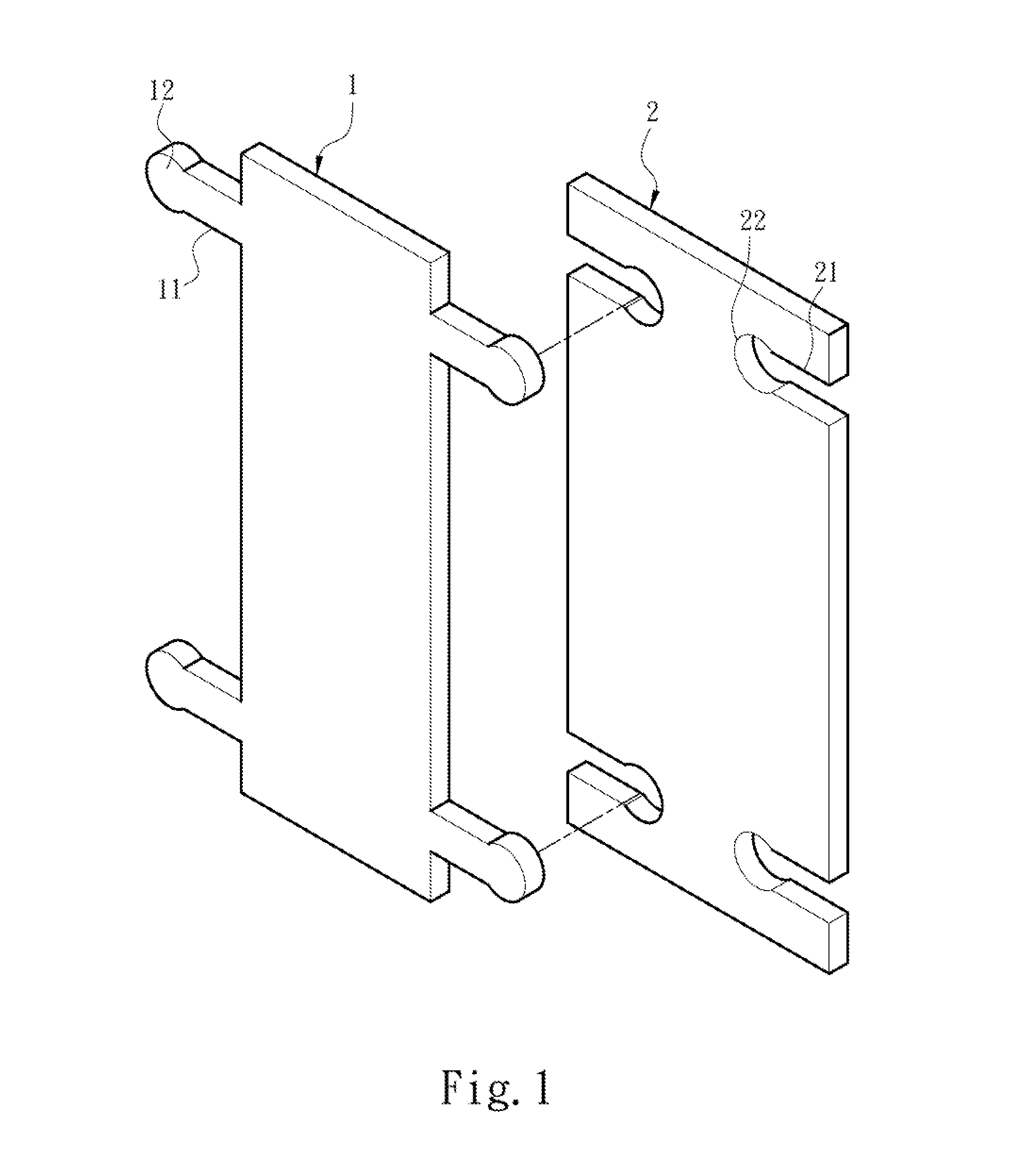

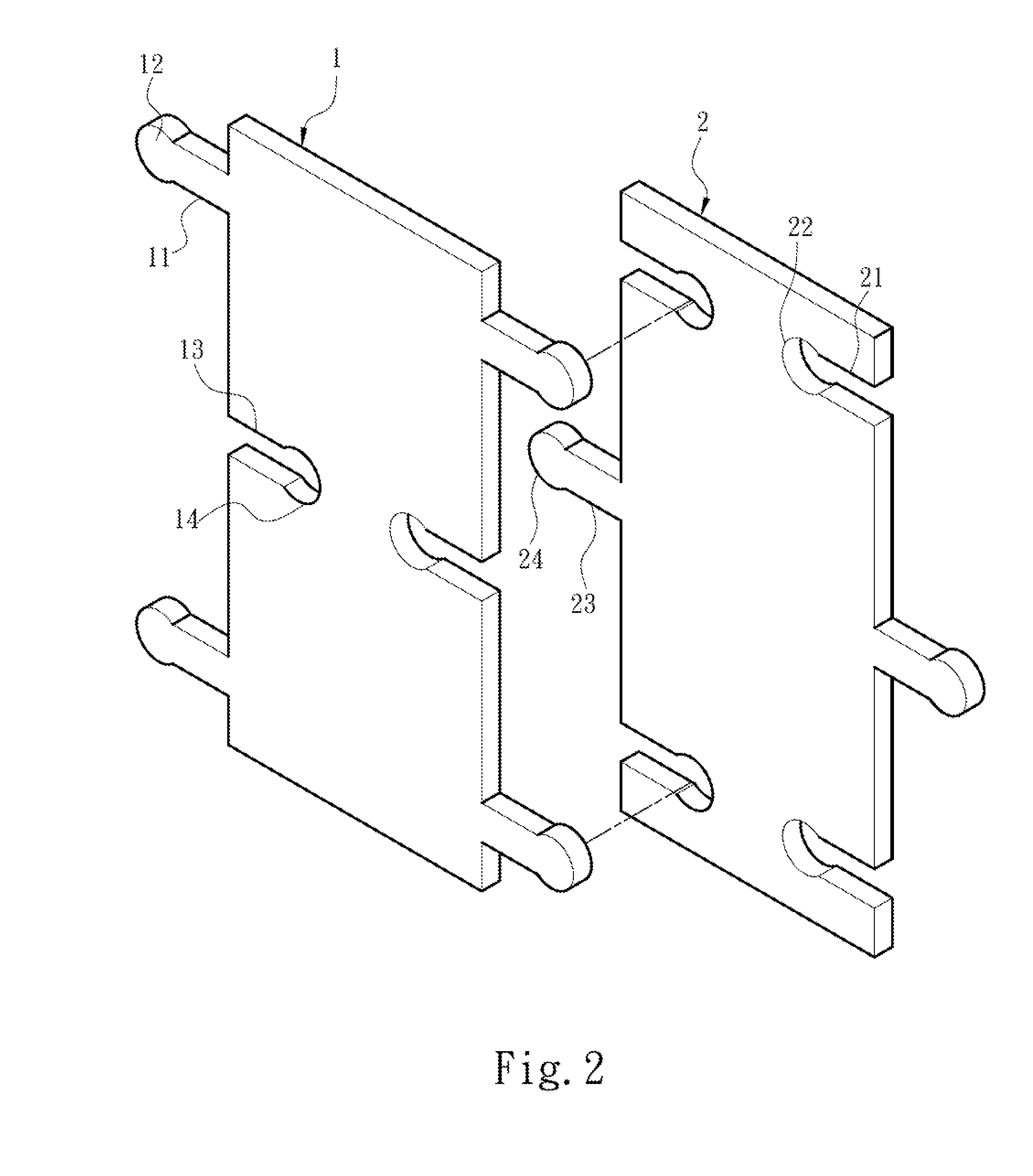

[0028]Referring to FIG. 1 and FIG. 2, a packaging cushioning structure of the present invention is formed by mutually splicing a first cushioning body 1 and a second cushioning body 2. Each of the first cushioning body 1 and the second cushioning body 2 is made of a cushioning material, e.g., corrugated paper, a plastic material or other materials having an appropriate rigidness. Further, at at least one side of the first cushioning body 1, the first cushioning body 1 includes at least one first assembly portion 11 and a first clamping portion 12 connected to the first assembly portion 11. At at least one side of the second cushioning body 2, the second cushioning body 2 includes a second assembly portion 21 and a second clamping portion 22 connected to the second assembly portion 21. The second assembly portion 21 may lock and fasten the first assembly portion 11, and the second clamping portion 22 may lock and fasten the first clamping portion 12, such that the second cushioning b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap