Compact firearm spring arrangement

a compact, firearm technology, applied in the field of magazines, can solve the problems of difficult loading of firearm magazines, inability to use conical springs in magazines, etc., and achieve the effects of reducing height, free length, and increasing spring force density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

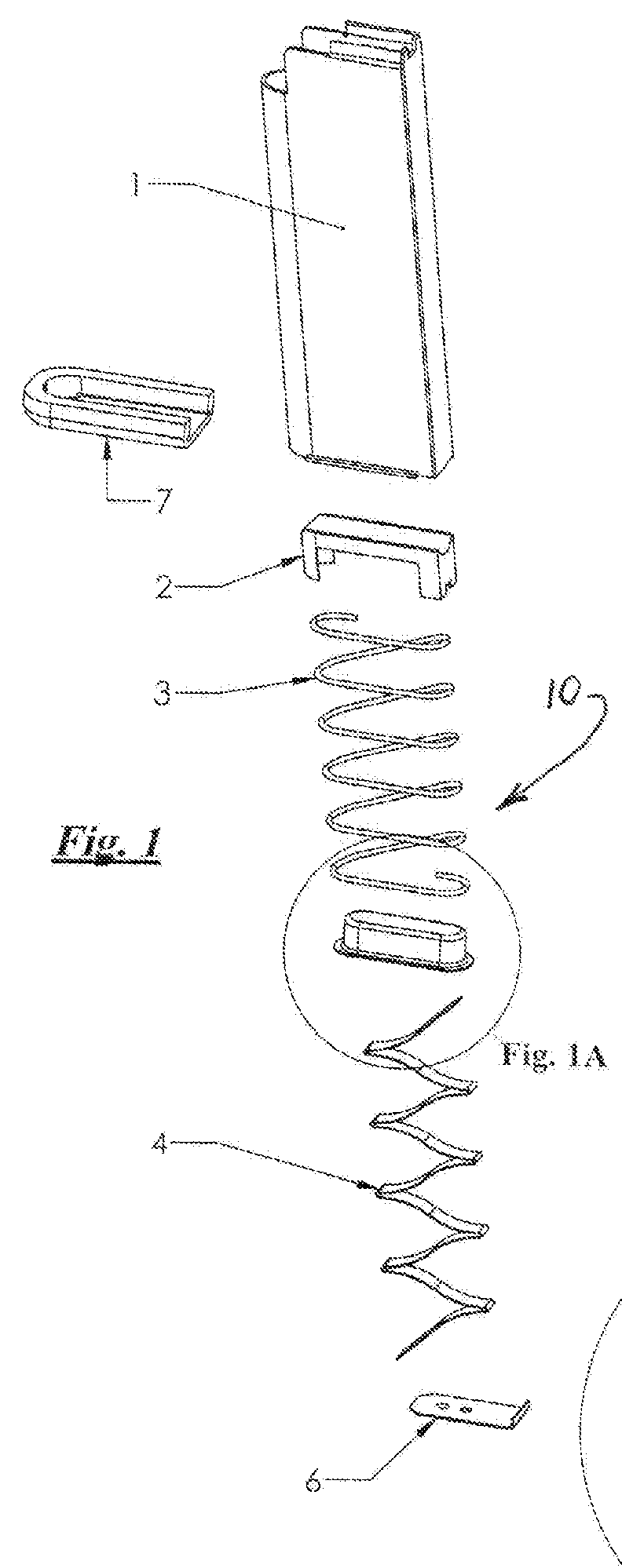

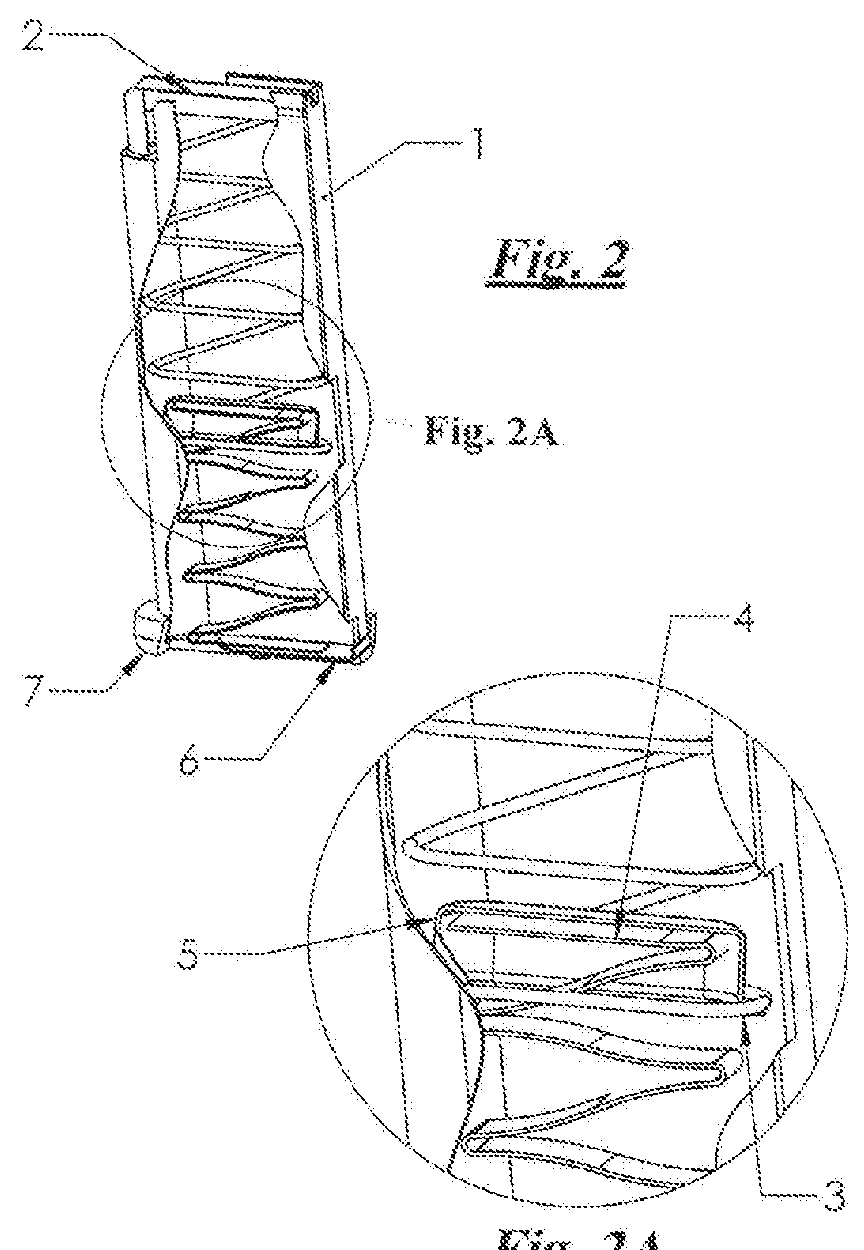

[0018]Referring to the several views of the drawings, the compact firearm spring arrangement of the present invention is shown and generally indicated as 10.

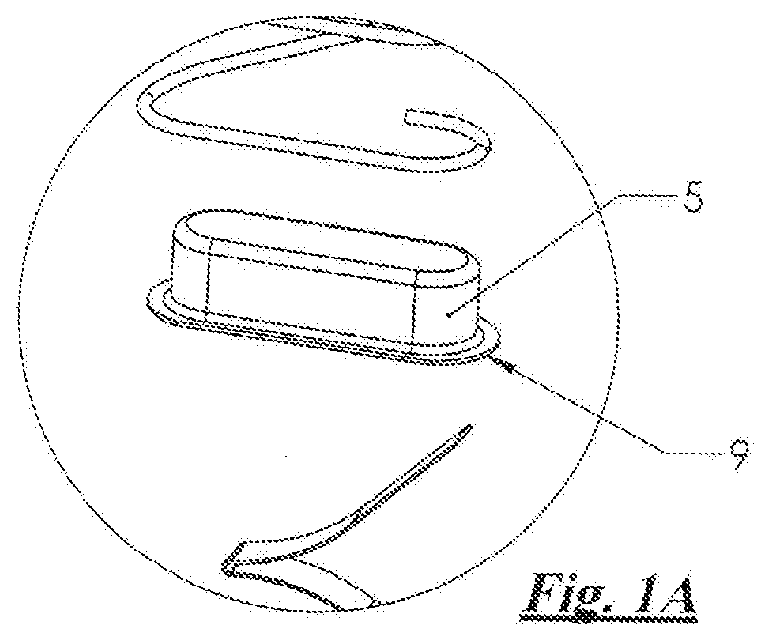

[0019]A hollow, generally rectangular-shaped magazine tube 1 includes a follower 2, a primary compression spring 3, a secondary compression spring 4, and a spring connecting cup 5. The bottom end of the tube 1 is closed by an integrally connected or removable bottom plate 7. The tube 1 defines an interior chamber sized for storing bullets 8 for use by a firearm. Where the bottom plate 7 is removable, as shown in FIGS. 1-3A, a lock plate 6 is used for preventing the bottom plate 7 from inadvertently sliding off the magazine tube 1. The tube 1, follower 2, and spring connecting cup 5 may each be formed of metal, plastic, or any other suitable material. The primary compression spring 3 may be formed of materials commonly known in the art, such as music wire. The secondary compression spring 4 is a flat spring and can be manufacture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com