Plug connector

a technology of plug-side connectors and connector elements, which is applied in the field of plug-side connector elements, can solve the problems of short-circuiting, damage to the pins and the shells of both connector elements, and the inability to remove the plug-side connector element from the receptacle-side connector element easily, so as to achieve accurate and secure connections or coupling between the connector elements. easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

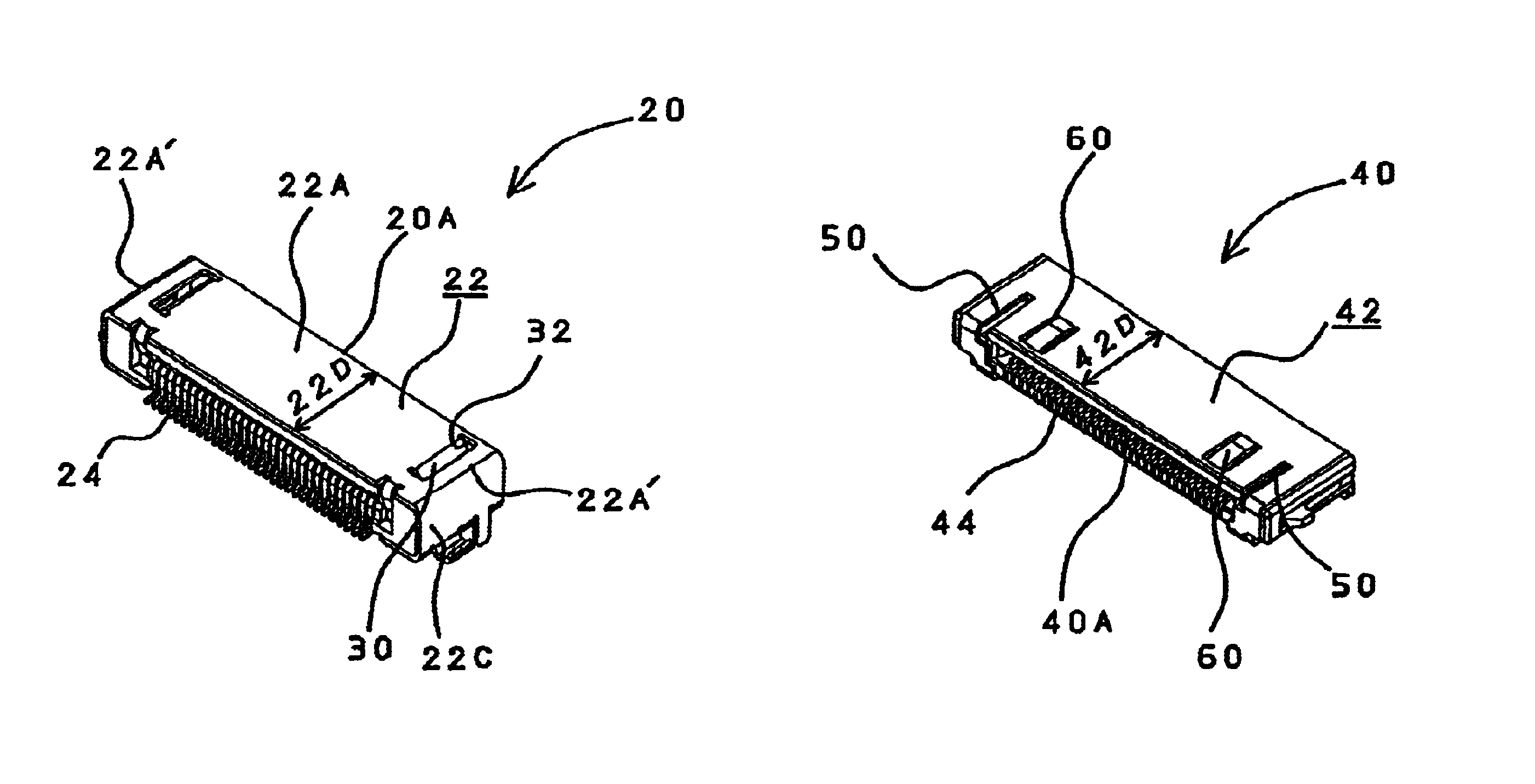

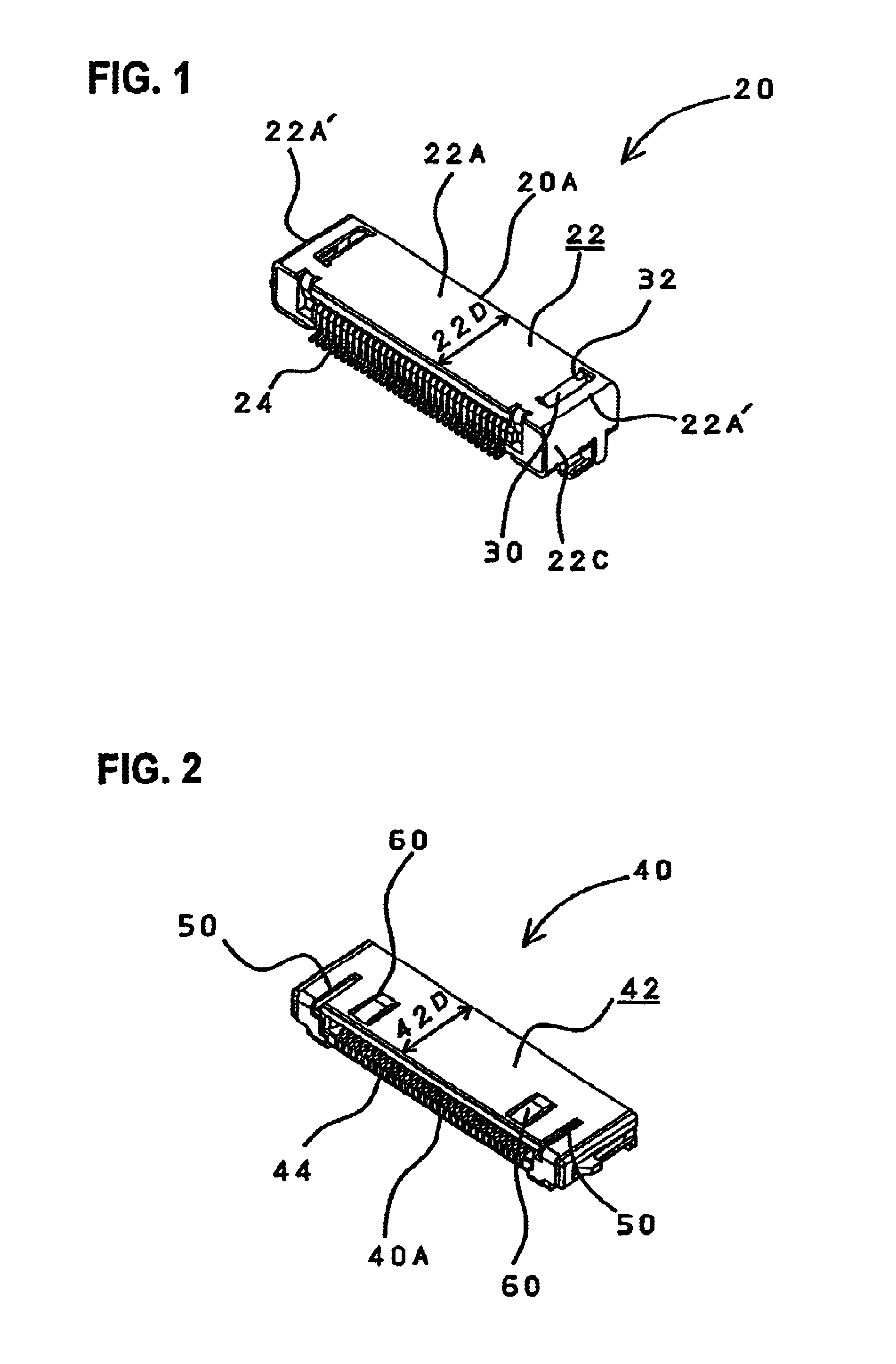

[0025]The connector of the present invention is comprised of a first connector body 20 (a receptacle side connector element) and a second connector body 40 (a plug side connector element).

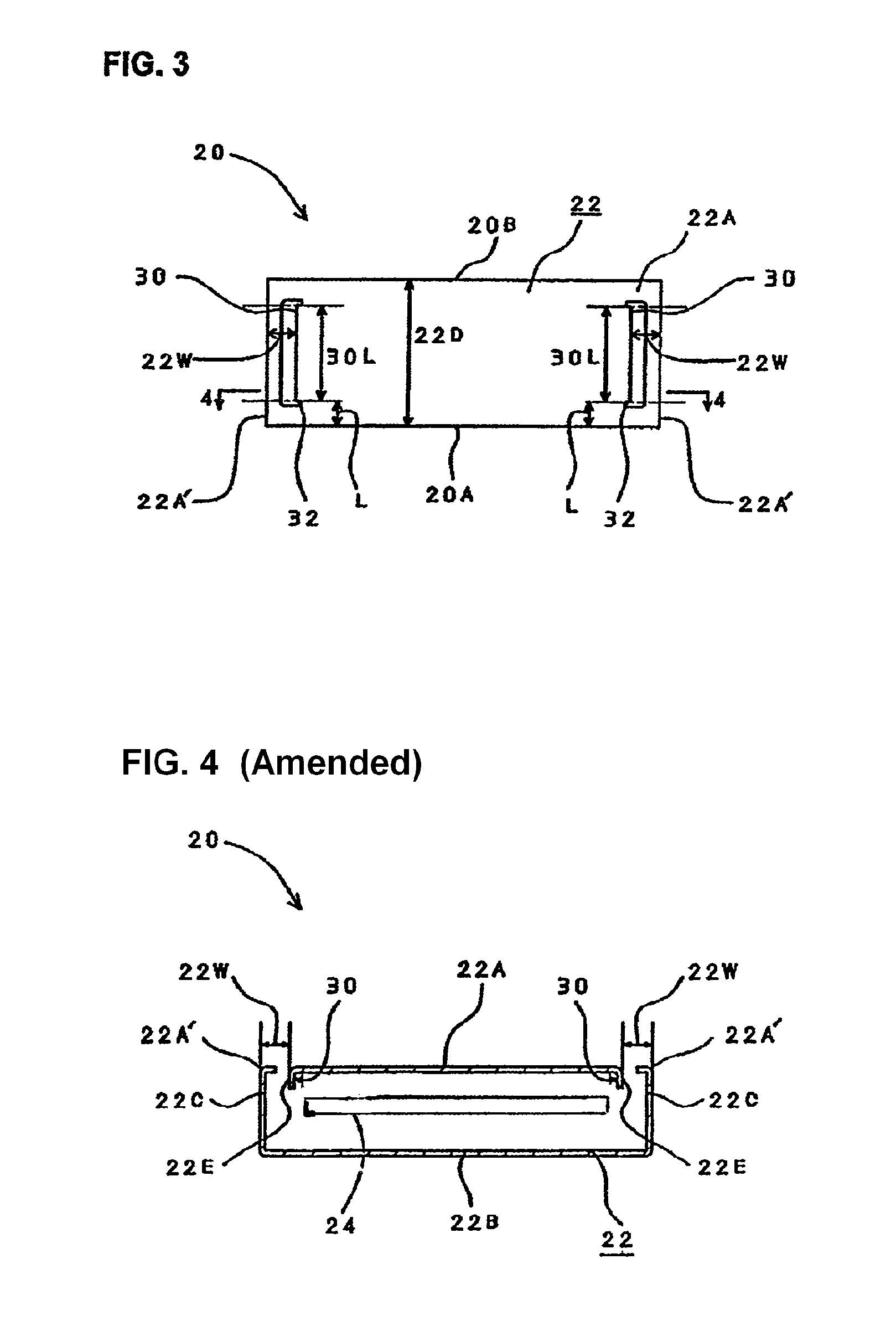

[0026]As seen from FIGS. 1 and 2, the first and second connector bodies 20 and 40 comprise respectively a relatively flat box shape shell 22 and 42 made of a metal and include therein a plurality of pins or elongated electrodes, which are collectively referred to by the reference numerals 24 and 44 respectively, and an insulating material (not shown) is filled therein so as to positionally secure the pins 24 and 44.

[0027]The shell 22 of the first connector body 20 comprises, as best seen from FIG. 4, a top shell plate 22A and a bottom shell plate 22B as well as side shell plates 22C, thus forming a box shape that has a predetermined depth 22D (see FIG. 3) that extends from the front edge 20A to the rear edge 20B of the first connector body 20. The pins 24 of the first connector body 20 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com