Hydrophobic nano particles and process for preparing dispersion liquid thereof

A nanoparticle and lipophilic technology, which is applied in the field of preparation of lipophilic magnetic nanoparticles and their dispersions, can solve the problems of incompleteness and reduce the dispersing ability of magnetic nanoparticles, and achieve a large density value and good hydrophilic dispersion. Characteristics, the effect of strong magnetic susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

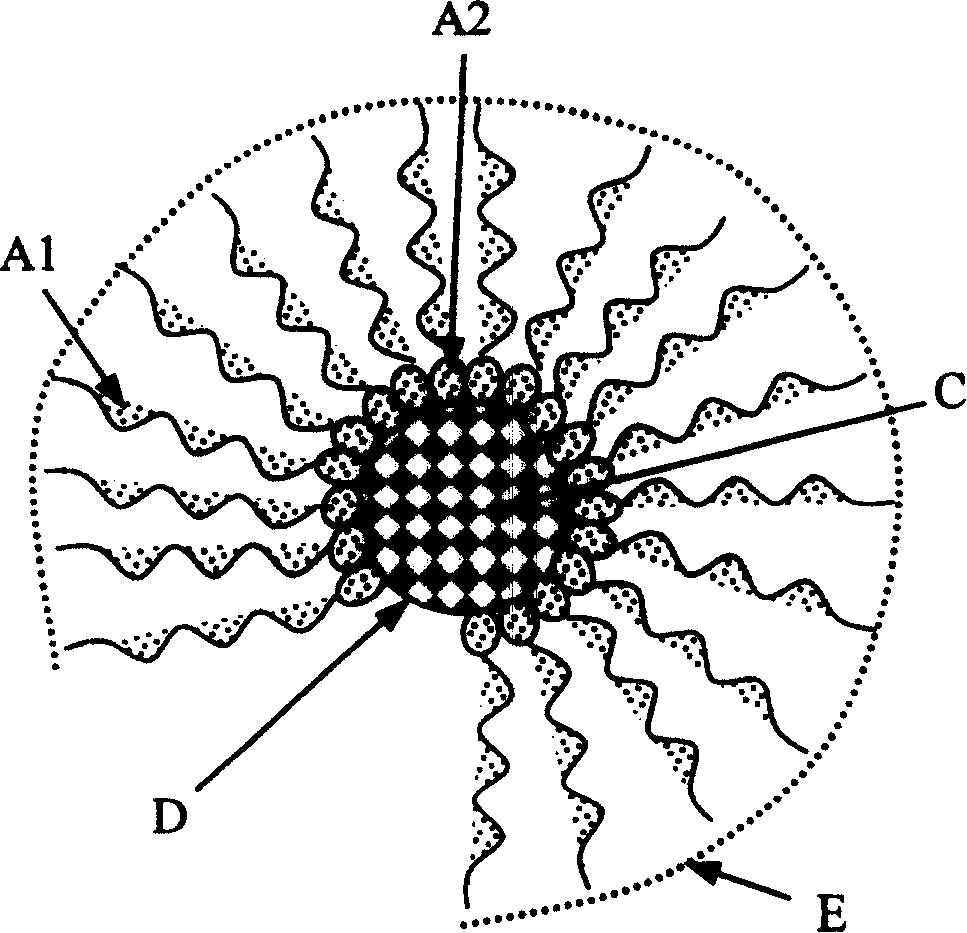

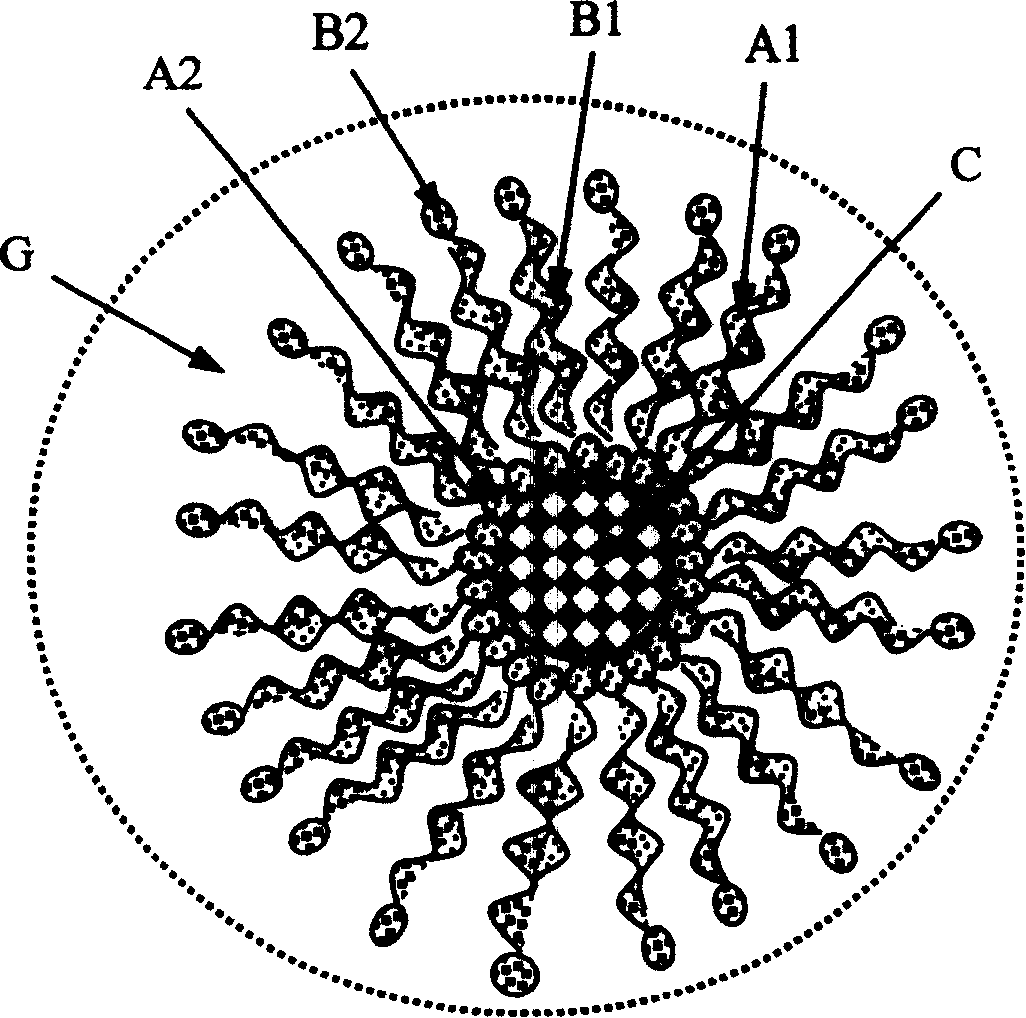

[0048] 0.2moL / L FeCl 2 and 0.4moL / L FeCl 3 Mix with concentrated ammonia water, react for 1 minute, add 200 times the amount of water at 10°C, stir at 10,000 rpm for 2.5 hours; separate the prepared Fe 3 o 4 Nanoparticles, washed twice with pure water, adding pH 8.4 aqueous solution under stirring at 4000rpm, then mixing with 2.5 times the calculated amount of sodium oleate under stirring at 4000rpm, heating and reacting at 85°C for 20 minutes, cooling to 25°C, adjusting pH to 5.2, using the method of applying an external magnetic field to separate the precipitated magnetic nanoparticles precipitate; the precipitate was washed once with acidic water of pH 4.2, then washed three times with pure water and then dried; the lipophilic Fe after drying 3 o 4 The particulate precipitate is directly dispersed in the diffusion pump oil to form lipophilic Fe 3 o 4 Magnetic nanodispersion liquid. The magnetic liquid film prepared from this dispersed liquid can exhibit strong magnetorh...

Embodiment 2

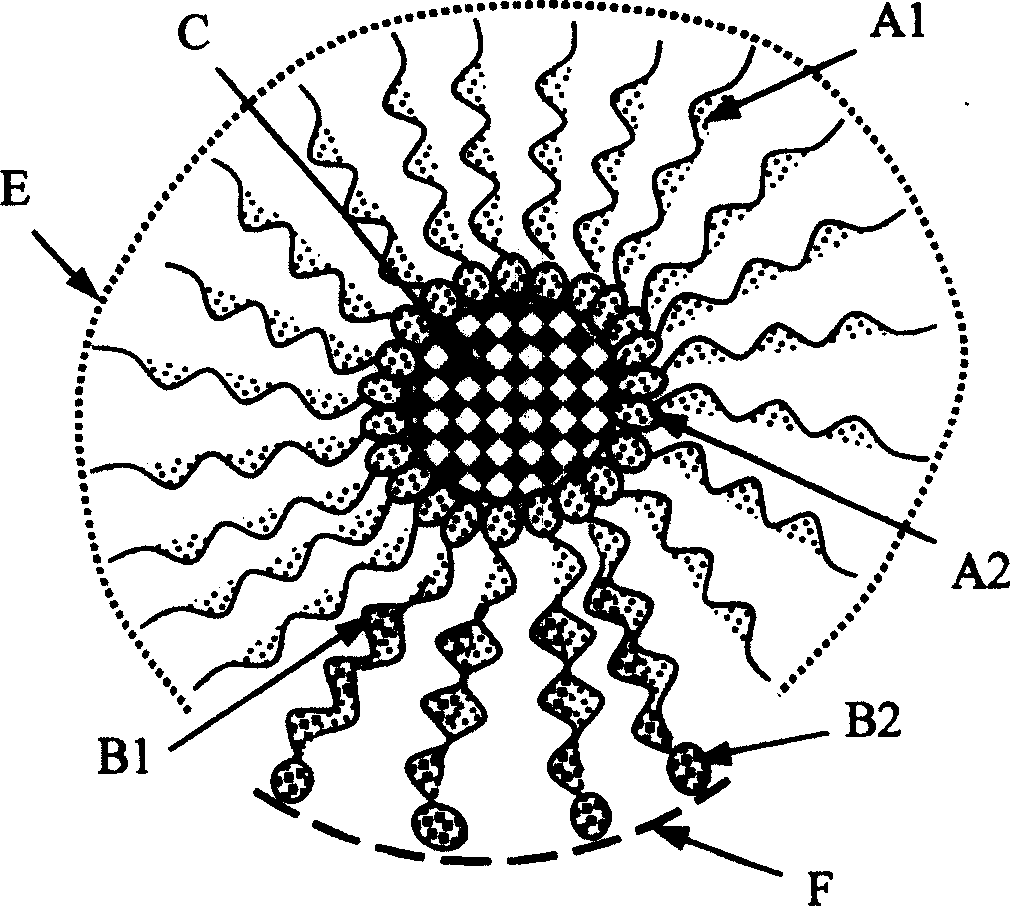

[0053] The prepared Fe 3 o 4 Nanoparticles were separated at 10000rpm, washed twice with pure water, added an aqueous solution of pH 9.2 under stirring at 4000rpm, then mixed with 2.3 times the amount of octyl phosphate under stirring at 6000rpm, heated and reacted at 90°C for 15 minutes, and then cooled to 25°C, adjust the pH to 4.6, and separate the precipitated magnetic nanoparticles by applying an external magnetic field; the precipitate is washed once with acidic water with pH 5.2, then washed with pure water three times and then dried; the lipophilic Fe after drying 3 o 4 Magnetic particle precipitation is directly dispersed in kerosene to obtain lipophilic Fe 3 0 4 Magnetic nanodispersion liquid.

Embodiment 3

[0055] The prepared Co x Ni (1-x) Fe 2 o 4 Nanoparticles are separated by applying a magnetic field, washed 3 times with pure water, added an aqueous solution with a pH of 10.5 under stirring at 6000rpm, and then mixed with 3 times the amount of sodium oleate under stirring at 5000rpm, and heated and reacted at 70°C for 40 minutes , cooled to 25°C, adjusted the pH to 5.3, and separated the precipitated magnetic nanoparticles by applying an external magnetic field; the precipitate was washed once with acidic water of pH 4.8, then washed three times with pure water and then dried; Ester Co x Ni (1-x) Fe 2 o 4 Magnetic particle precipitation was directly dispersed in olive oil to obtain lipophilic Co x Ni (1-x) Fe 2 o 4 Magnetic nanodispersion liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com