Resin composition

一种树脂组合物、聚烯烃树脂的技术,应用在合成树脂层状产品、运输和包装、化学仪器和方法等方向,能够解决低透明度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

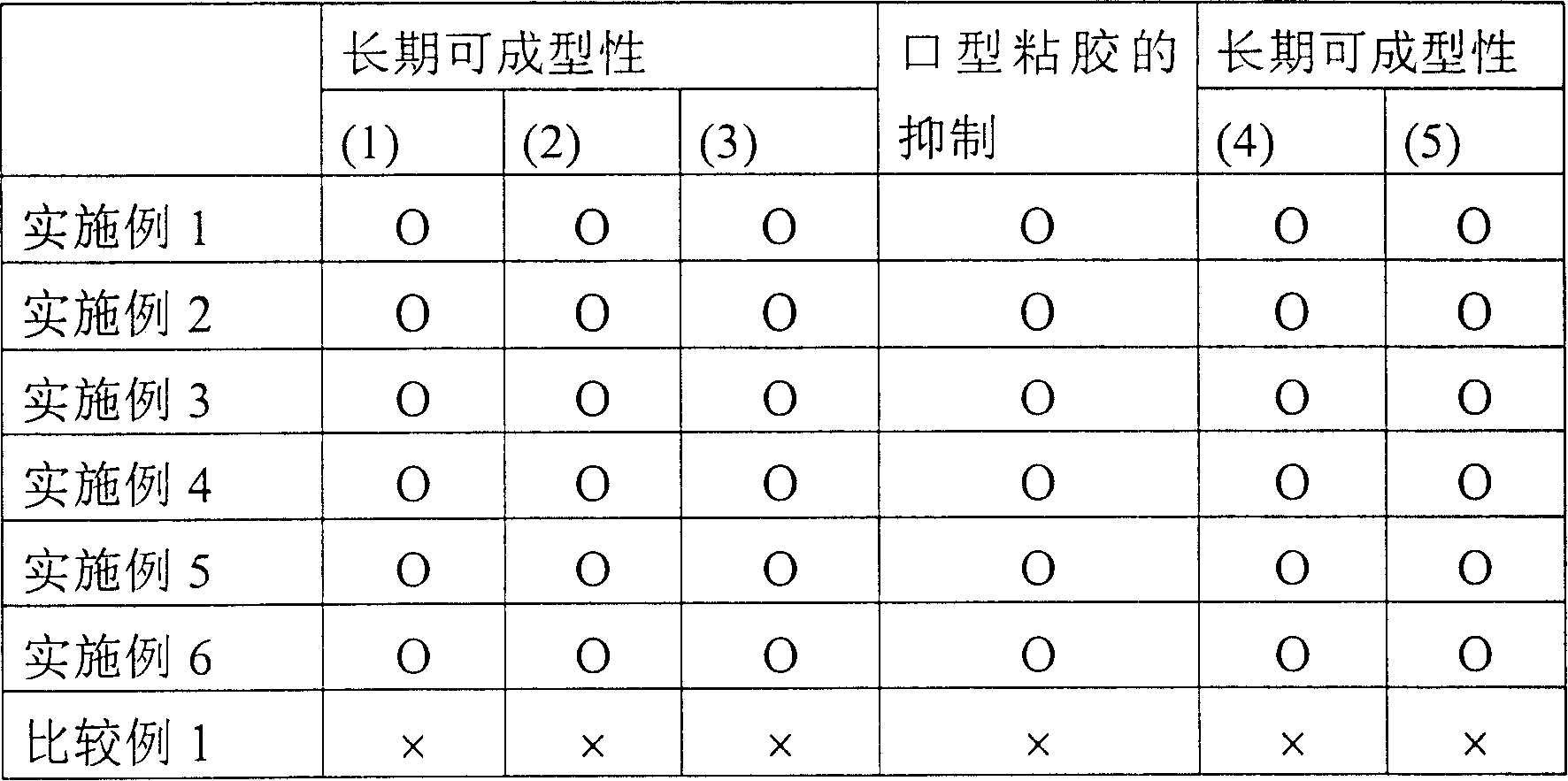

Examples

Embodiment 1

[0095] LDPE ["LF440B" manufactured by Japan Polychem Corporation, MFR 2.8g / 10min (190°C, 2160g load), density 0.925g / cm 3 ](A), 0.44MgO Mg(C 17 h 35 COO) 2 ["EM-144" manufactured by Eishin Kasei KK] (B), saponification product of ethylene-vinyl acetate copolymer ["MeltheneH6051" manufactured by Tosoh Corporation, ethylene content 89 mol%, saponification of vinyl acetate component The density is 100mol%, MFR is 5.5g / 10min (210 ℃, 2160g loading)] (C) and hydrotalcite solid solution ["ZHT4" produced by Kyowa Chemical Industry Co., Ltd., Mg 3 ZnAl 2 (OH) 12 CO 3 ·3H 2 O, the average particle size is 0.4 μm] (D) melt mixing at a weight ratio of A:B:C:D=70:10:15:5 to obtain the resin composition of the present invention.

[0096] Separately, EVOH [ethylene content is 32 mol%, degree of saponification is 99.6 mol%, MFR3.5g / 10min (210 ℃, load 2160g), boric acid containing 0.03 wt% based on boron weight], thermoplastic resin [polypropylene, composed of "AMOCO3143" manufactured ...

Embodiment 2

[0144] Except that "Melthene H6960" manufactured by Tosoh Corporation [ethylene content 82 mol%, saponification degree of vinyl acetate component 90 mol%, MFR 40 g / 10 min (210°C, 2160 g load)] was used as ethylene-vinyl acetate copolymer Except for the saponified product (C), the resin composition of the present invention was obtained in the same manner as in Example 1, and similar evaluations were carried out.

Embodiment 3

[0146] In addition to using "FY6C" [PP manufactured by Japan Polychem Corporation, MFR is 2.4g / 10min (190°C, 2160g load), density is 0.90g / cm 3 ] (A) instead of LDPE (A), the same method as in Example 1 was used to obtain the resin composition of the present invention, and a similar evaluation was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com