Method of forming molding-flask-less, upper and lower molds and device therefor

A casting mold and sand box technology, which is applied to the modeling of upper and lower casting molds without a sand box and the field of molding devices, can solve the problems of low molding efficiency of the casting mold and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

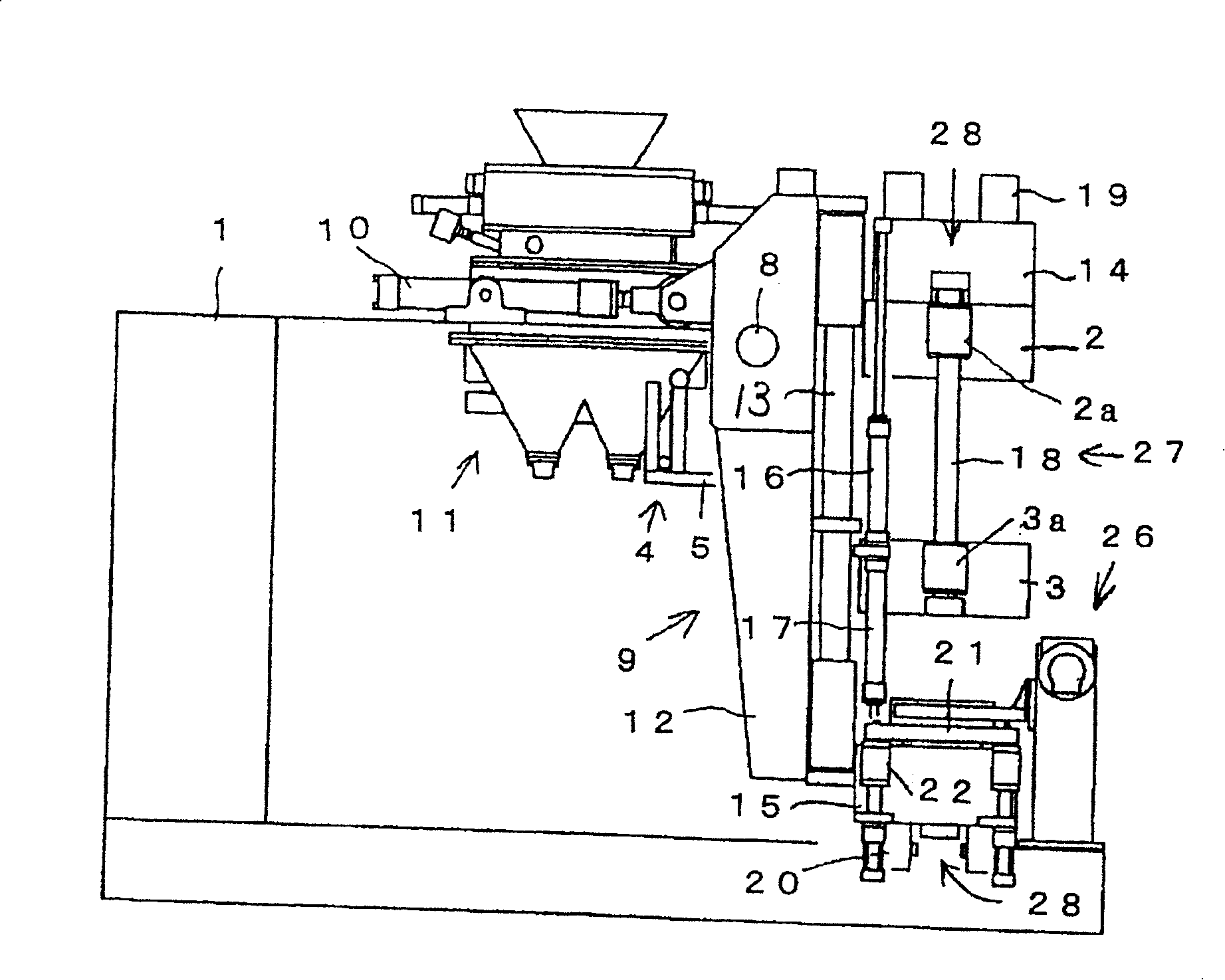

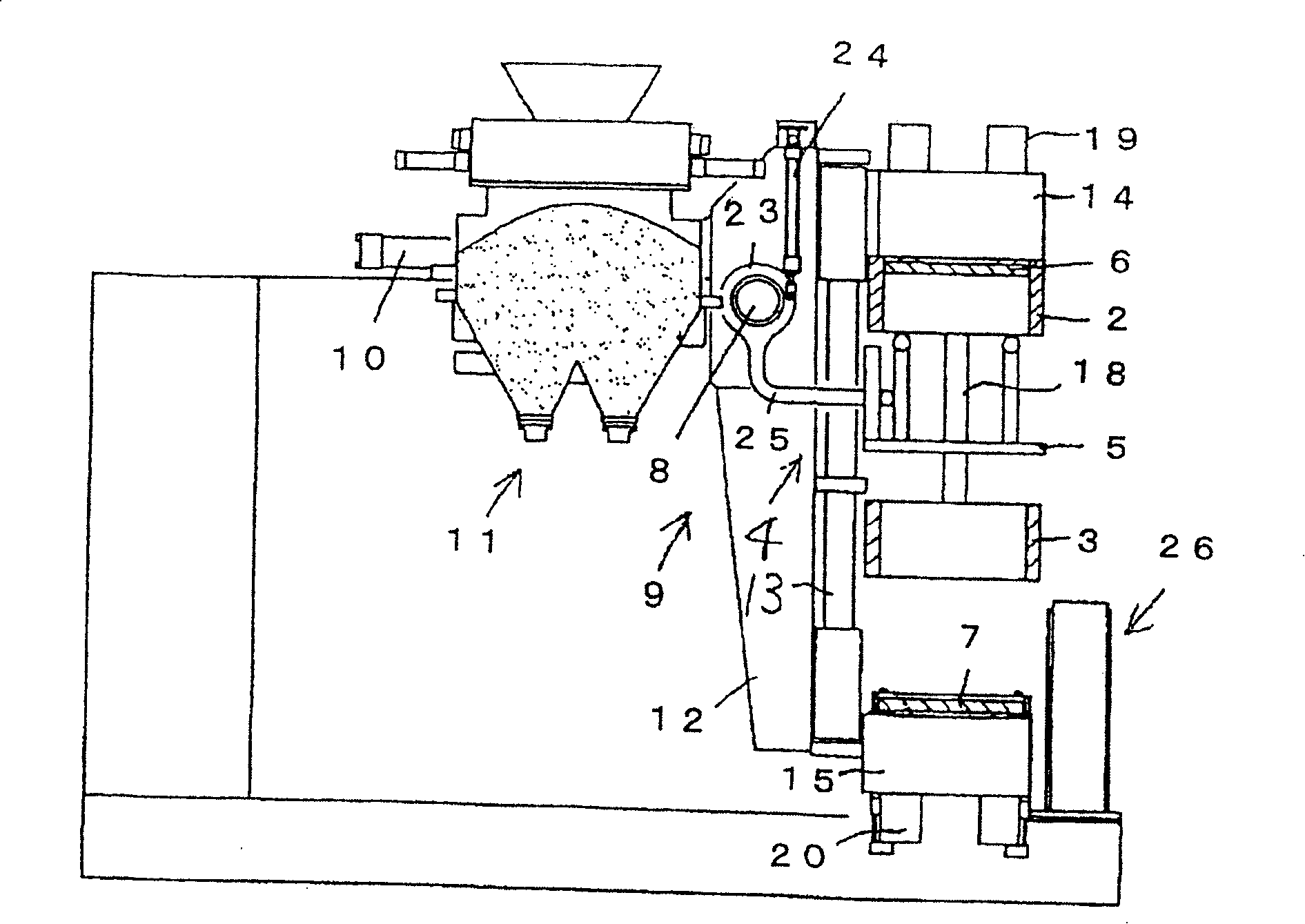

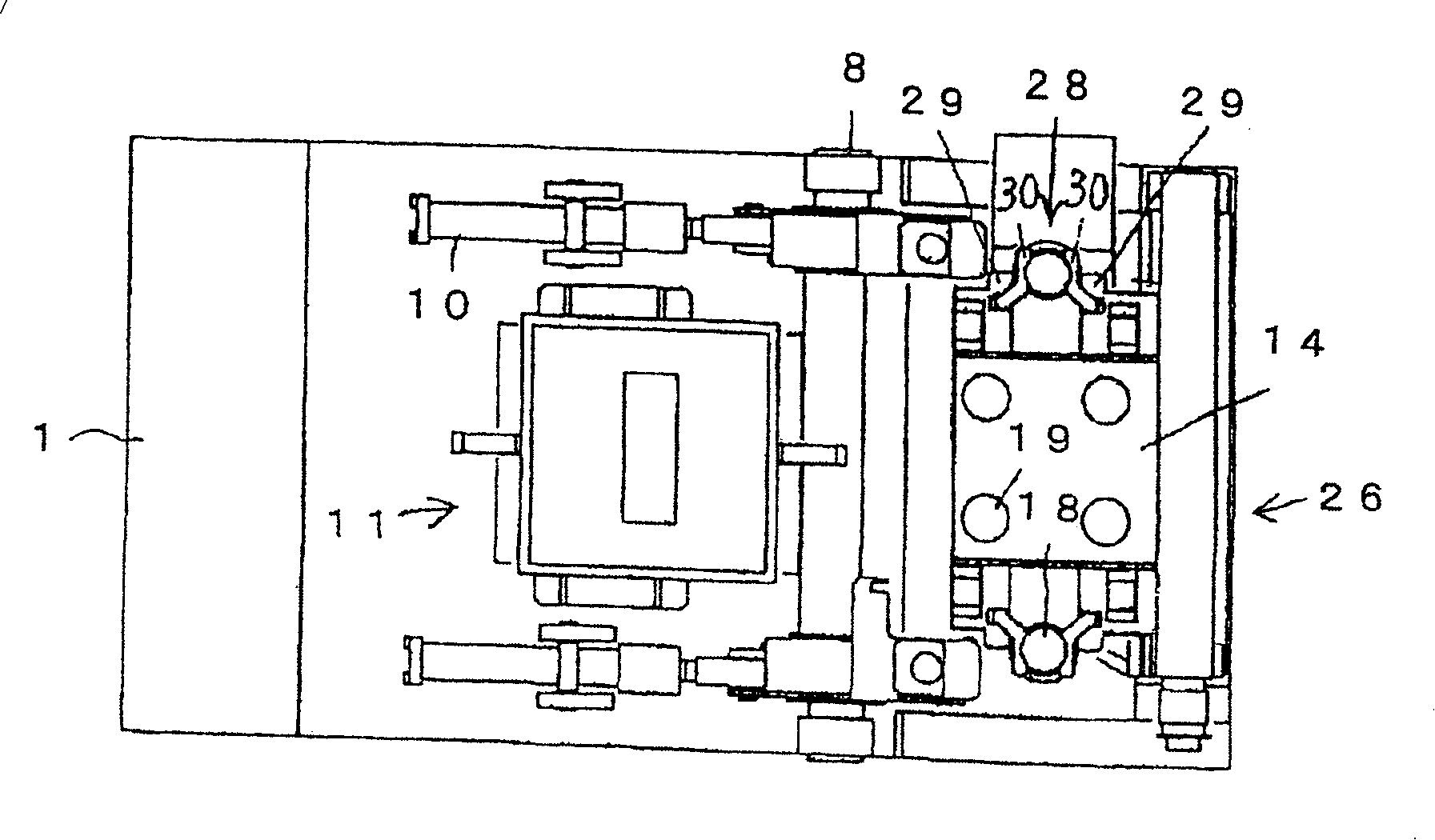

[0073] according to Figure 1-Figure 8 , will describe in detail the best embodiment of the upper and lower casting mold molding device applicable to the present invention.

[0074] Such as Figure 1-Figure 3 As shown, a molding device for an upper and lower casting mold without a flask includes: a machine 1 formed with an inner space;

[0075] It includes an upper and lower molding box assembly 27 with a pair of molding upper box 2 and molding lower box 3 respectively provided with molding sand blowing inlets on the side walls, wherein the molding upper box 2 and molding lower box 3 pass through a pair of connecting rods 18 , 18 are connected and can freely approach and stay away from each other;

[0076] The double-sided formwork 5 between the molding upper box and the molding lower box 2, 3 of the upper and lower sand box assembly 27 can be accessed by moving in and out of the mechanism 4;

[0077] the molding sand compression mechanism 9, which is arranged such that,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com