Template-free special-shaped sealing-head edge rotary cutting machine

A special-shaped head, no template technology, applied in the direction of metal processing equipment, manufacturing tools, copying process control system, etc., can solve the complex structure of hydraulic forming devices and molds, difficulty in purchasing and manufacturing for small and medium-sized producers, and reduce product manufacturing accuracy, etc. problem, achieve the effect of shortening the processing time, increasing the service life and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

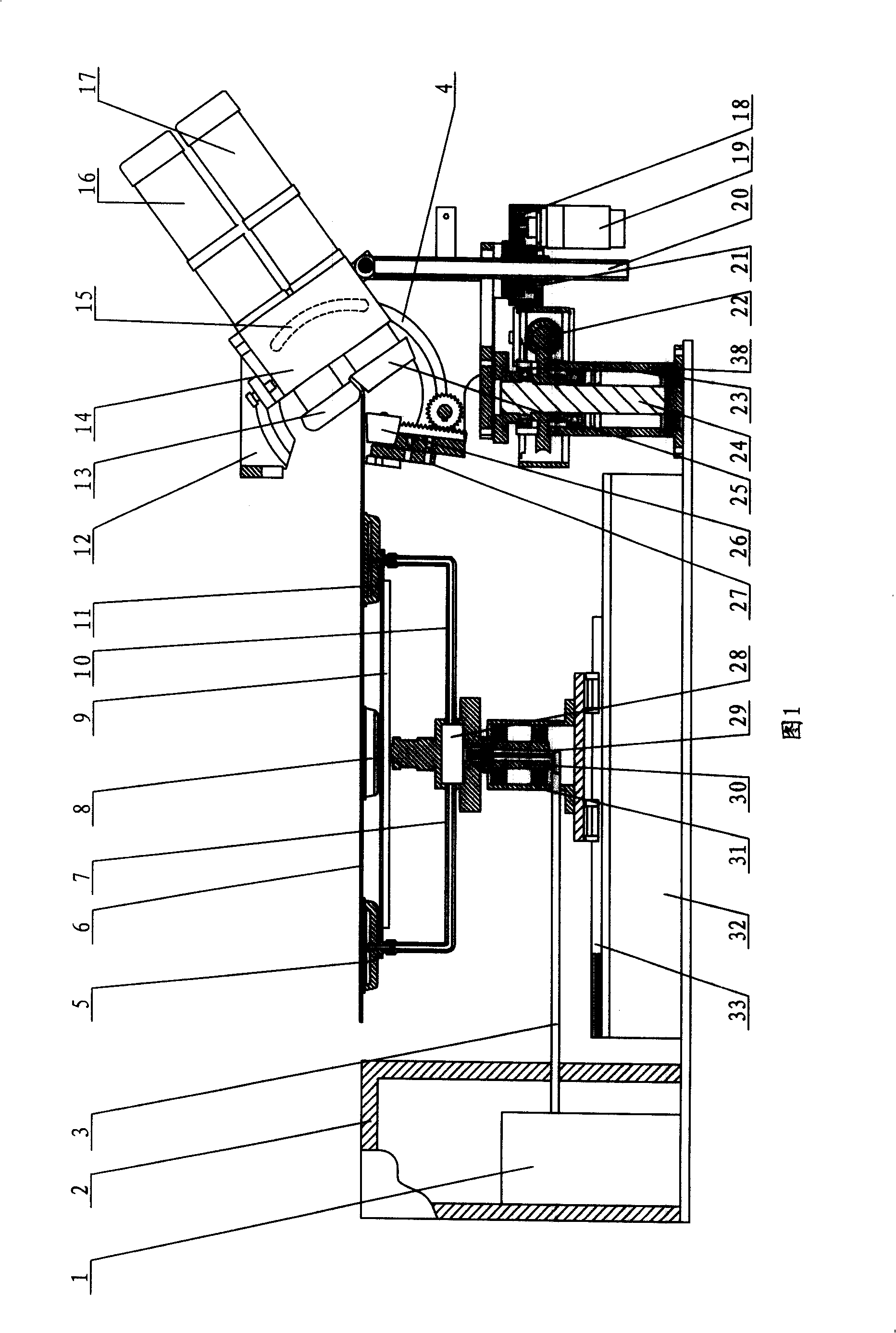

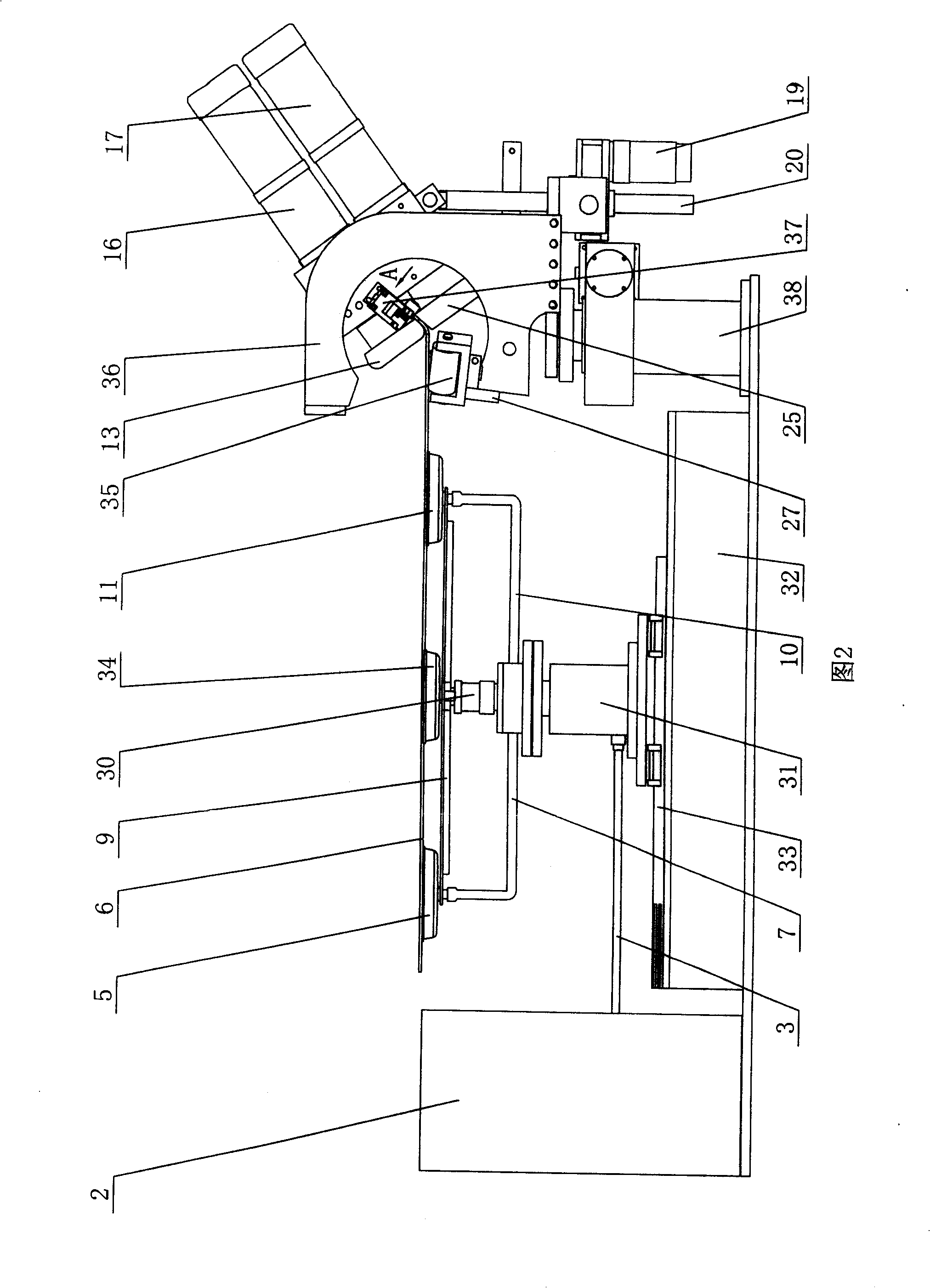

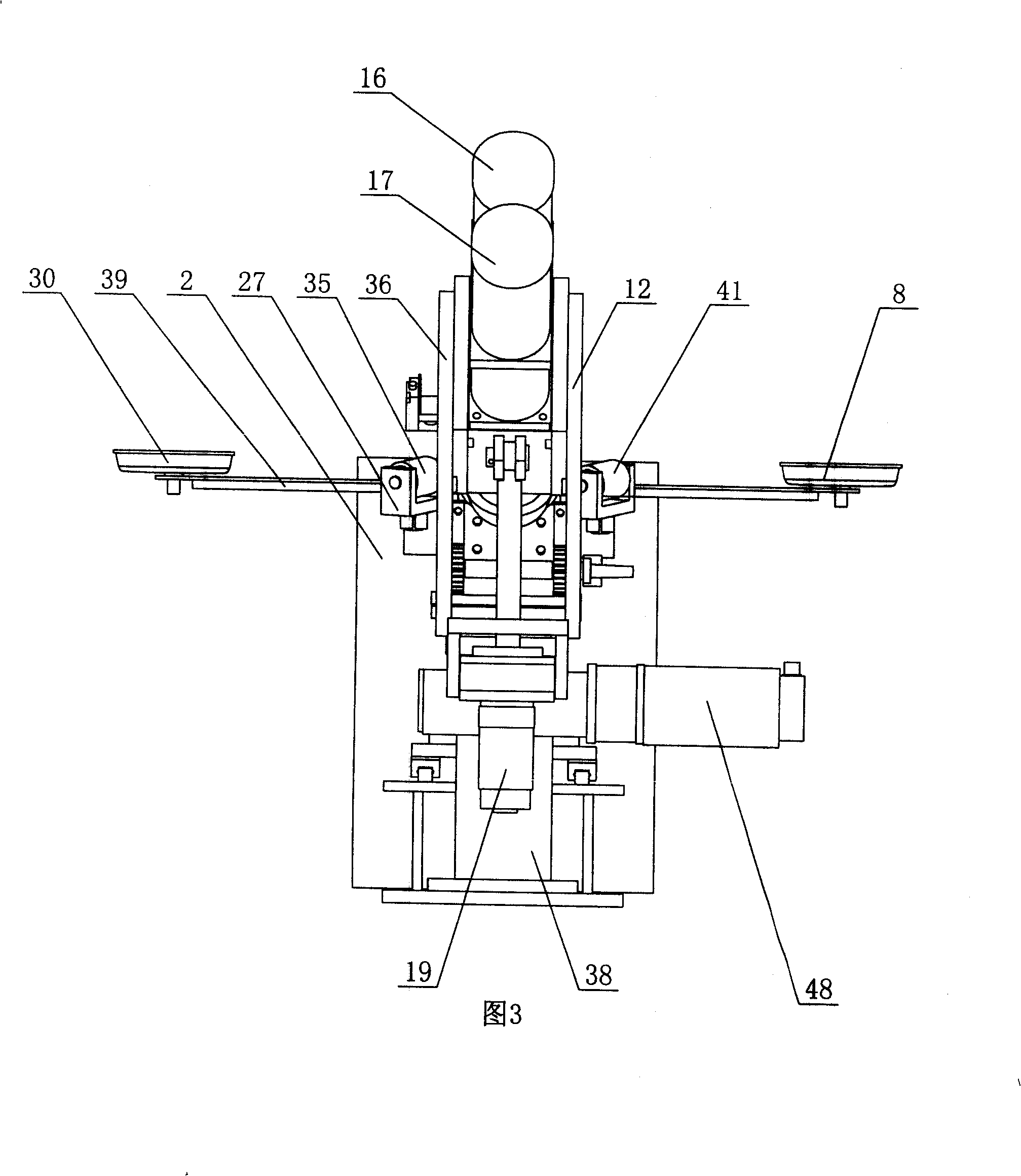

[0008] Templateless special-shaped head edging machine, it has a base 38, the first shaft 24 is installed in the base 38, the upper end of the first shaft 24 passes out of the base 38 and connects with the first support plate 36 and the second support plate 12 Connect, movable seat 14 is installed between the first support plate 36 and the second support plate 12, upper pressure roller 13 and lower pressure roller 25 are installed on the movable seat 14, upper pressure roller 13 is connected with the output shaft of first motor 16, the lower The pinch wheel 25 is connected with the output shaft of the second motor 17, and a profiling device 37 is installed on the movable seat 14. The profiling device 37 is connected by profiling support 41, sensor 42, profiling connecting rod 40, connecting rod 45 and profiling wheel 47; The middle part is hinged, and the profiling wheel 47 is installed on one end of the profiling connecting rod 40, and the profiling wheel 47 is located betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com