Machine of turning rim for shaped cap seal head

A special-shaped head and edge machine technology, applied in the direction of duplication process control system, metal processing equipment, manufacturing tools, etc., can solve the problems of lower product manufacturing accuracy, low manufacturing efficiency, and difficult maintenance, so as to save human resources and increase usage Long life, safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

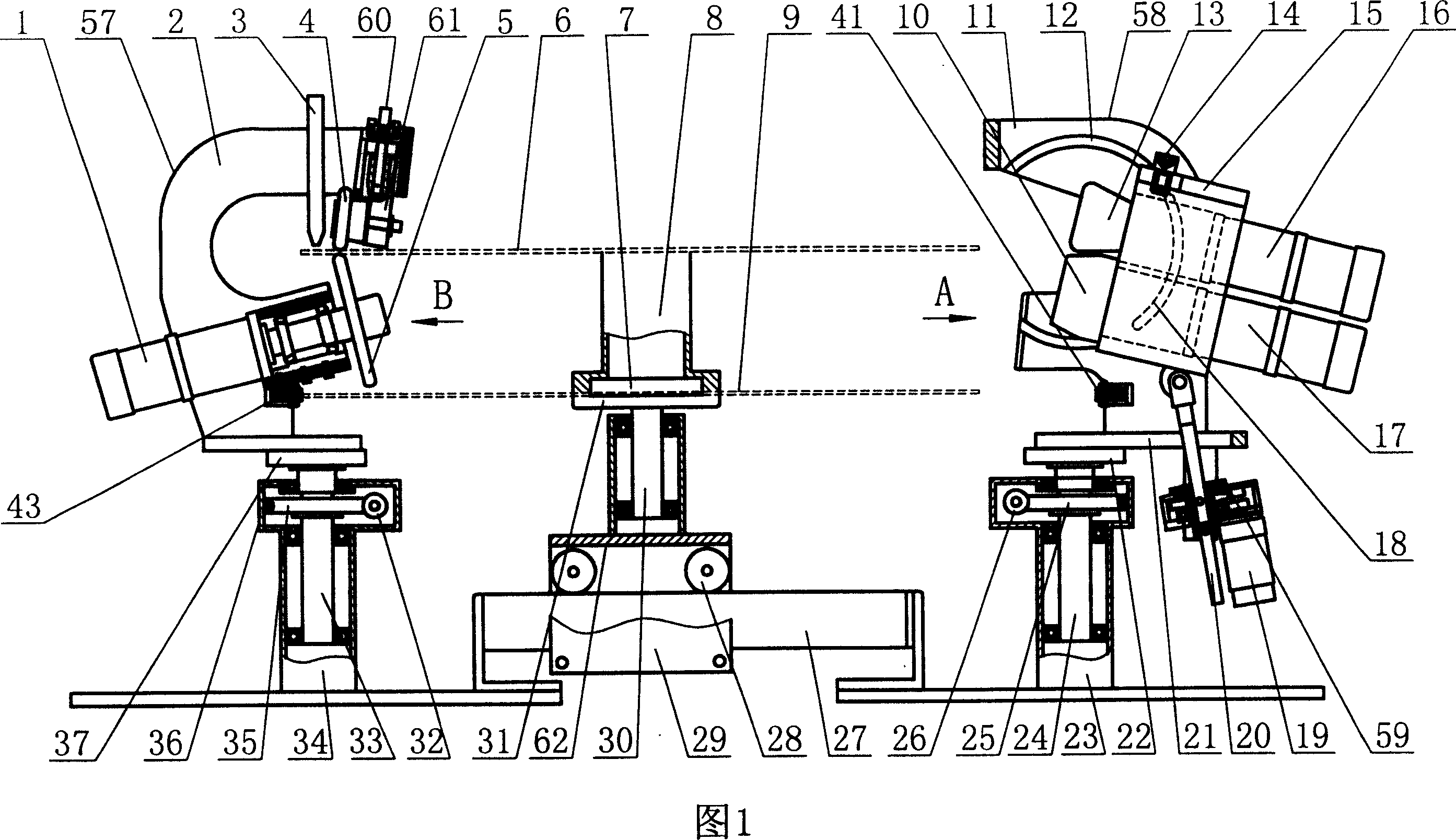

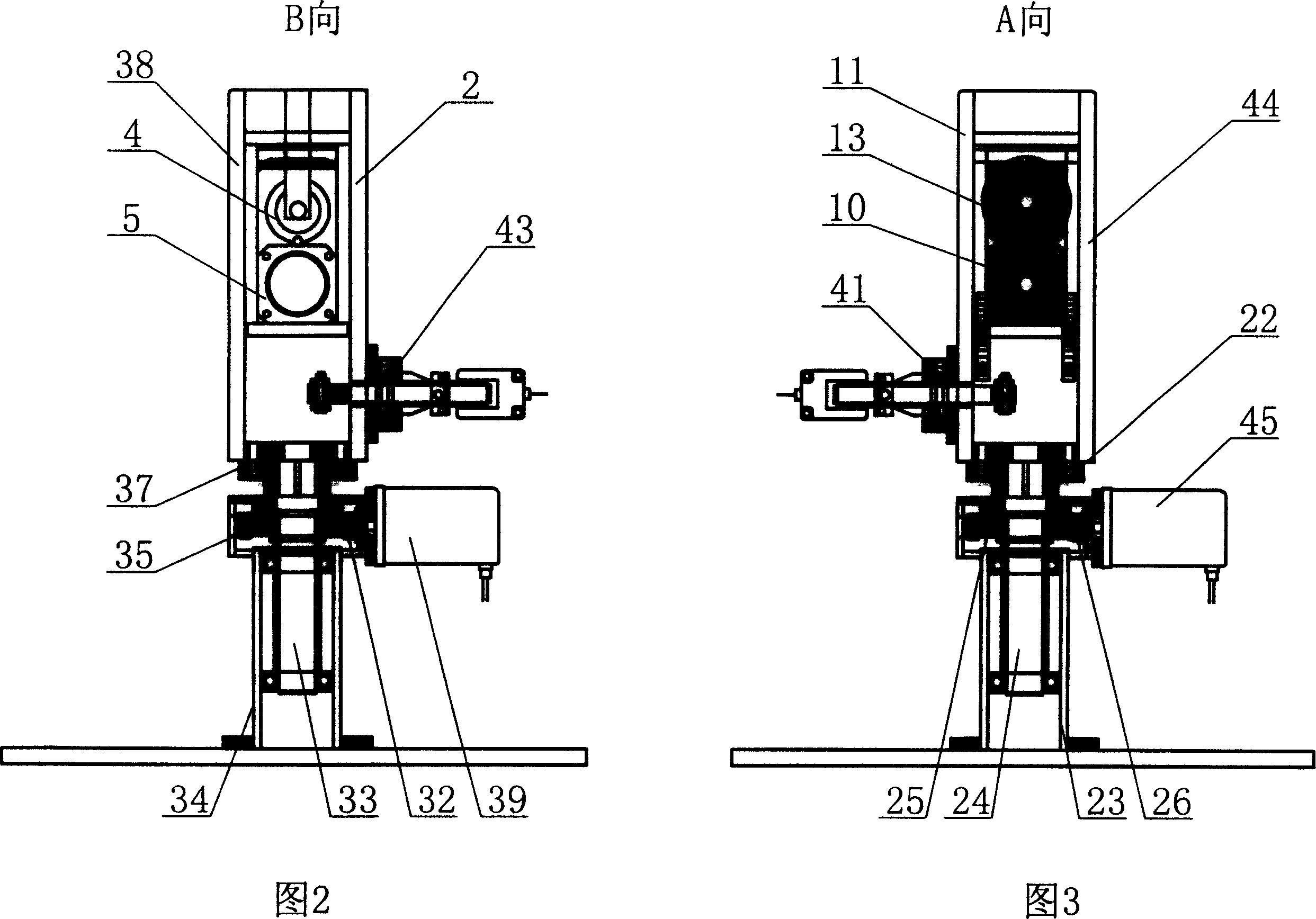

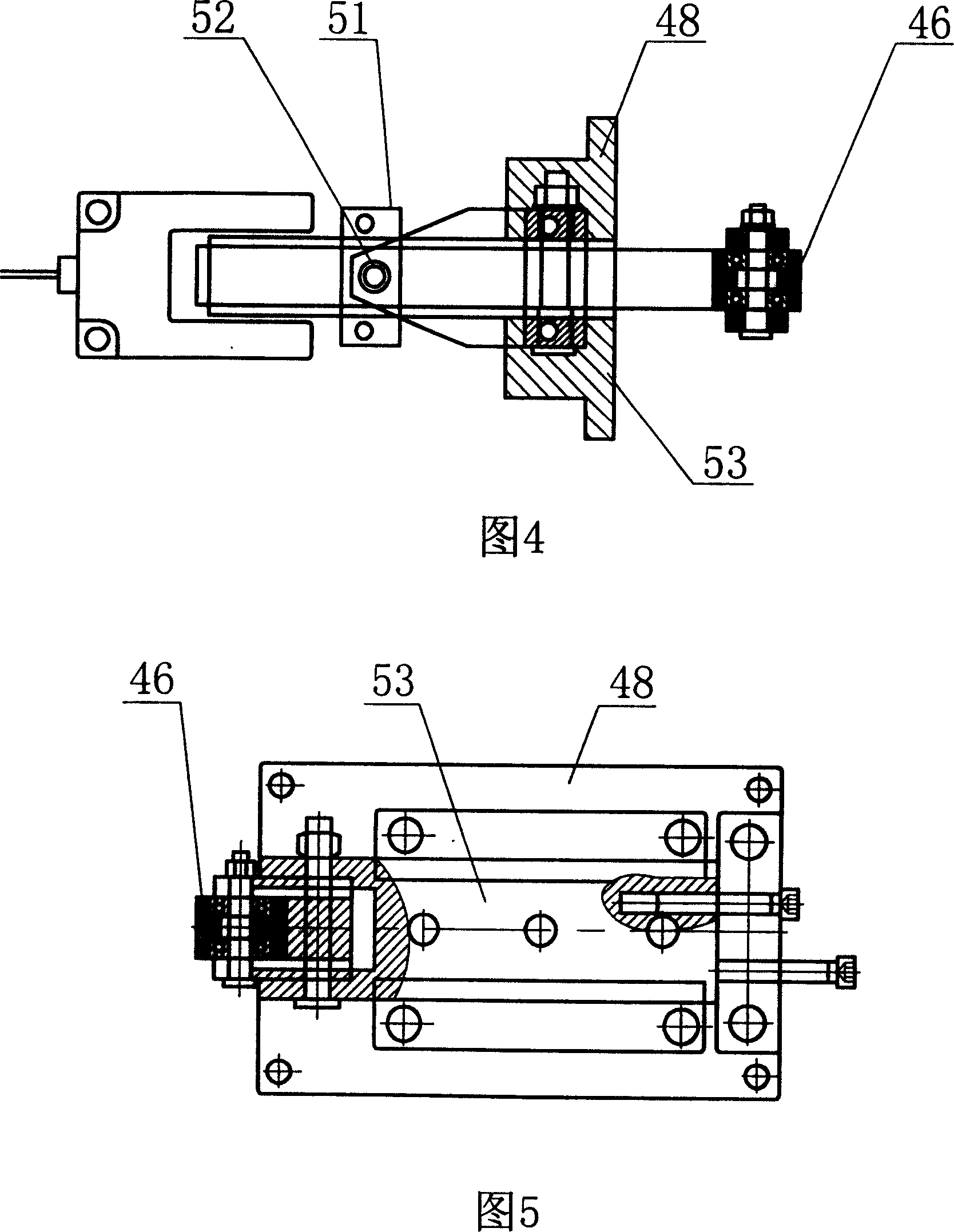

[0008] Special-shaped head edging machine, it has a first base 23, a first shaft 24 is installed in the first base 23, the upper end of the first shaft 24 passes through the first base 23 and is connected with the first bracket 58, the first bracket 58 is formed by connecting the first support plate 11 and the second support plate 44. A movable seat 15 is installed between the first support plate 11 and the second support plate 44, and the upper pressure roller 13 and the lower pressure roller 10 are installed on the movable seat 15. The wheel 13 is connected with the output shaft of the upper reduction motor 16, the lower pressing wheel 10 is connected with the output shaft of the lower reduction motor 17, and the first profiling device 41 is installed on the first support 58. The inner wall of the first support plate 11 is provided with a first arc-shaped groove 12 , and the side wall of the movable seat 15 is provided with an arc-shaped protrusion 18 , and the arc-shaped pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com