Method and device for preparing zinc oxide nano-crystal based on non ionization radiation

A technology of nanocrystals and infrared rays, applied in the field of ceramic materials, can solve problems such as difficult separation, difficult deposition of ZnO nanocrystals, and inability to form temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

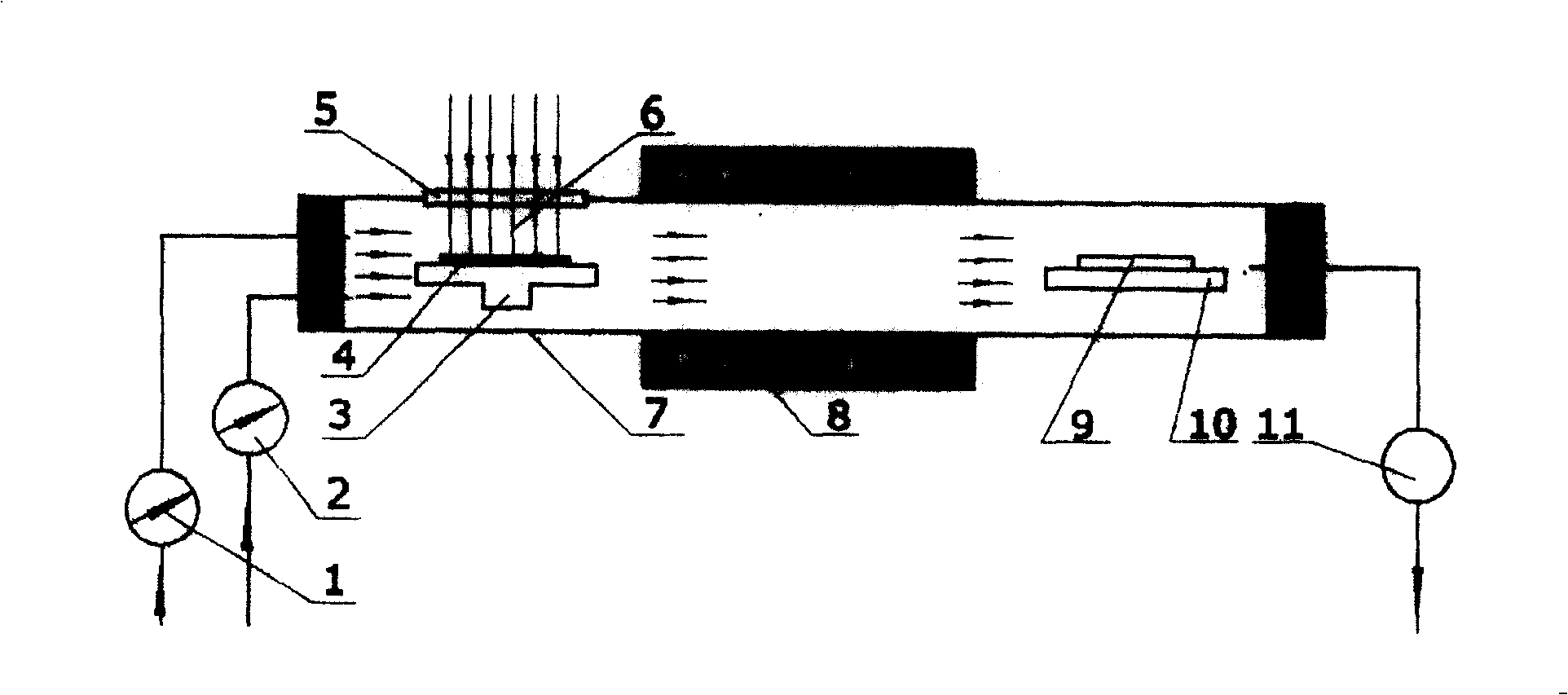

[0017] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Carrying out gas phase oxidation with the present invention prepares zinc oxide nano crystal device to comprise: O 2 Flow meter 1, Ar flow meter 2., workbench 3, metal zinc plate 4, K9 glass window 5, continuous laser, reaction furnace 7, heating furnace 8, base 9, base 10, vacuum pump 11.

[0019] Wherein the K9 glass window 5 is set on the top of the reaction furnace 7, and O is connected on the left side of the reaction furnace 7 2 The flowmeter 1 and the Ar flowmeter 2 are provided with a workbench 3 for placing a metal zinc plate 4 in the middle of the reaction furnace 7, a continuous laser is provided above the corresponding reaction furnace 7, and a A susceptor 10 on which a substrate 9 is placed, and a vacuum pump 11 is provided on the right side of the heating furnace 8 .

[0020]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com