Tap

A faucet and faucet technology, applied in the field of faucets, can solve the problems of complicated operation, long labor consumption, inability to use plastic materials, etc., and achieve the effect of reducing the use cost and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

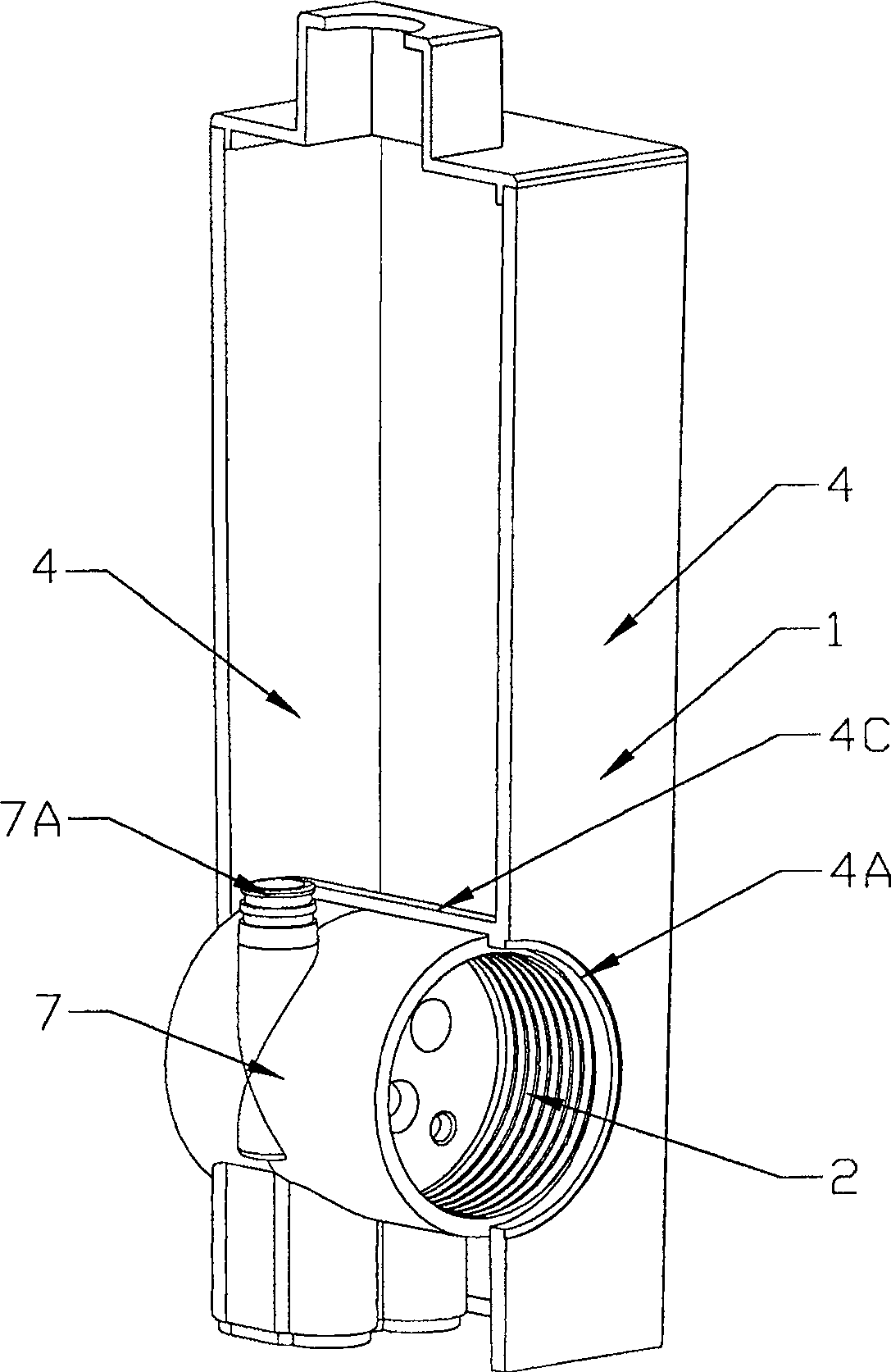

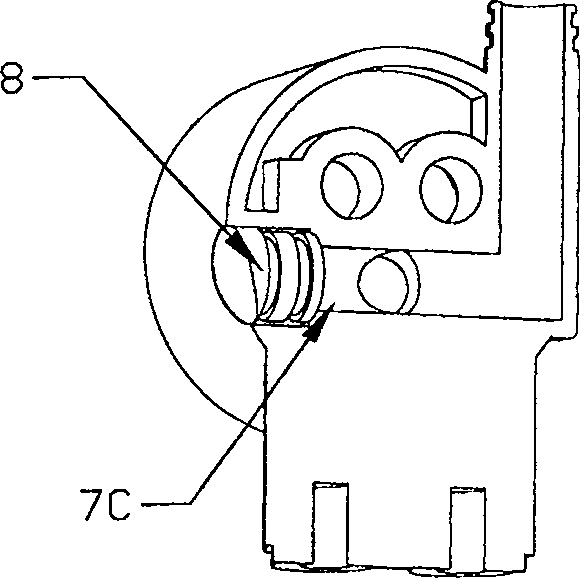

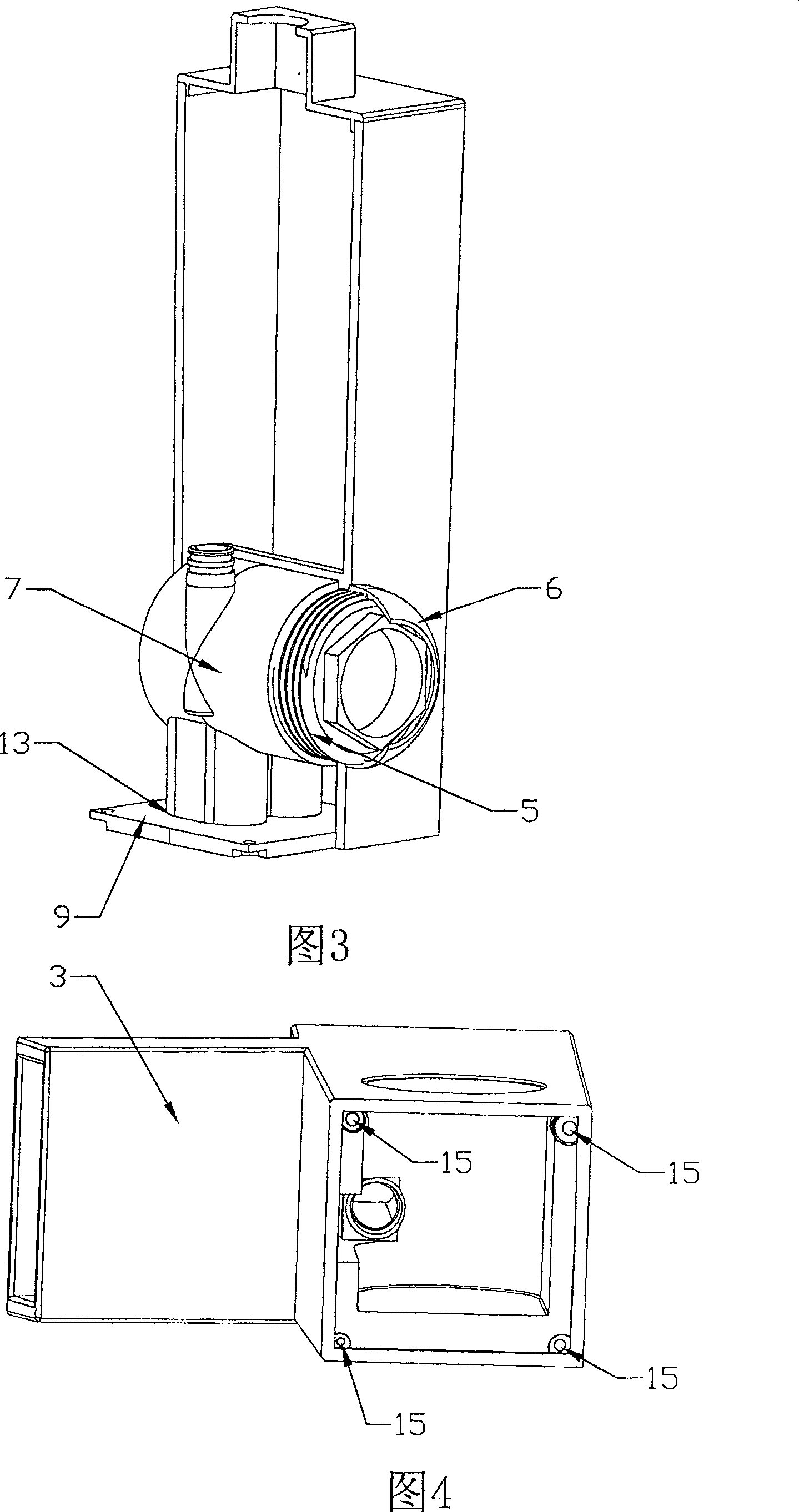

[0016] Such as figure 1 , figure 2 , Figure 3, Figure 4, Figure 5 As shown, the faucet provided by the present invention includes a main faucet housing 1, and the main faucet housing 1 includes an outer shell 4 and an inner core 7, on which the valve seat 2 is arranged on the inner core 7, and on the outer shell 4, the valve seat 2 should be set. There is a valve seat installation hole 4A in the position, and the valve seat 2 is aligned with the valve seat installation hole 4A. The valve seat 2 is equipped with a decorative cover 6 and a control handle. The outer shell 4 and the inner core 7 can be assembled to form a complete faucet main shell 1. This split structure is convenient for mass production and maintenance and replacement.

[0017] Such as figure 1 , Figure 3, Figure 4, on the basis of the above embodiment, the valve seat 2 provided on the inner core 7 does not extend beyond the inner wall of the outer shell 4. Since the valve seat 2 of a general split-type fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com