Radiating fan and base of fan frame

A heat dissipation fan and frame technology, which is applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems of electronic component loss and shortened life span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

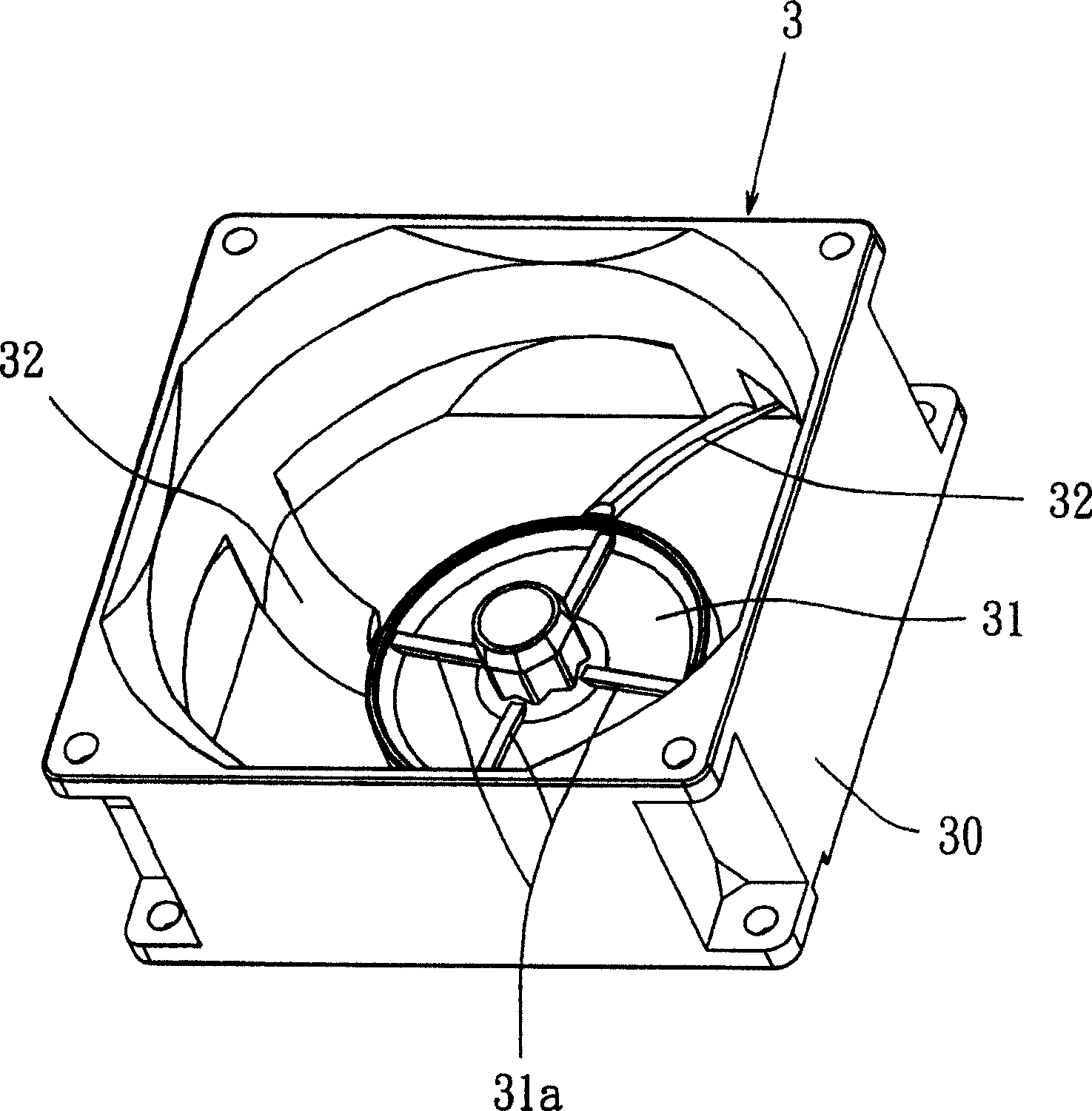

[0054] First, see image 3 , which shows a preferred embodiment of one of the fan frame seats used in the cooling fan of the present invention. The fan frame seat 3 includes an outer frame 30; a base 31 is arranged in the outer frame for supporting the impeller of the heat dissipation fan; and a plurality of deflectors 32 are arranged on the base 31 Between the outer frame 30, the plurality of deflectors are located on the side of the air outlet of the fan frame seat. Certainly, the deflector can also be arranged on the air inlet side of the fan frame seat, or be located on the air inlet side and the air outlet side of the fan frame seat at the same time. The shape of the frame is in addition to the image 3 Instead of being shown as a square configuration, it could also be a rectangular or circular configuration. The outer frame, the base and the plurality of deflectors can be integrally formed by injection molding, and the materials used can be plastic, metal or other sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com