Radiating fan and its frame structure

A heat dissipation fan and frame technology, applied in cooling/ventilation/heating transformation, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve problems such as poor sound quality and large noise value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

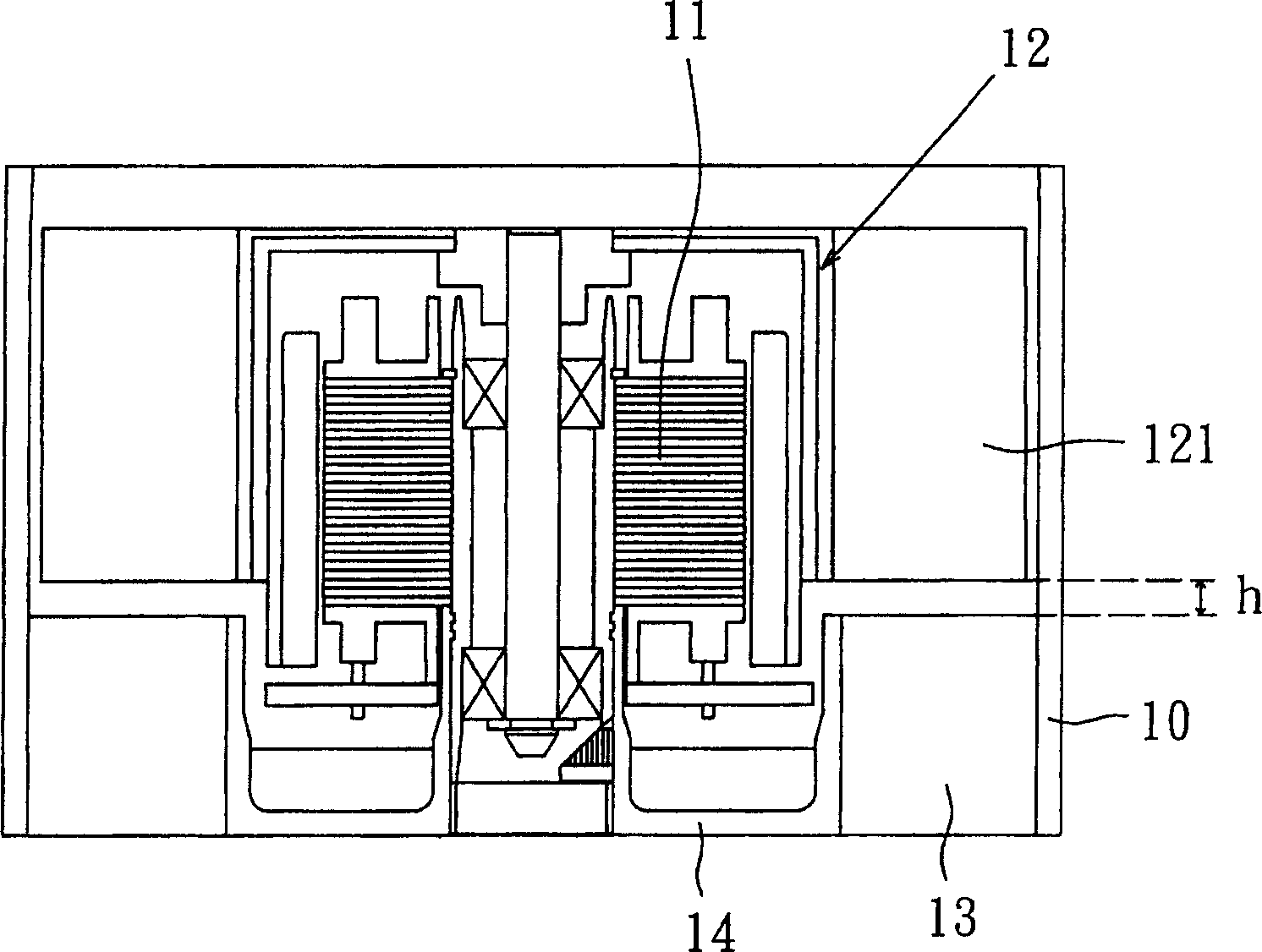

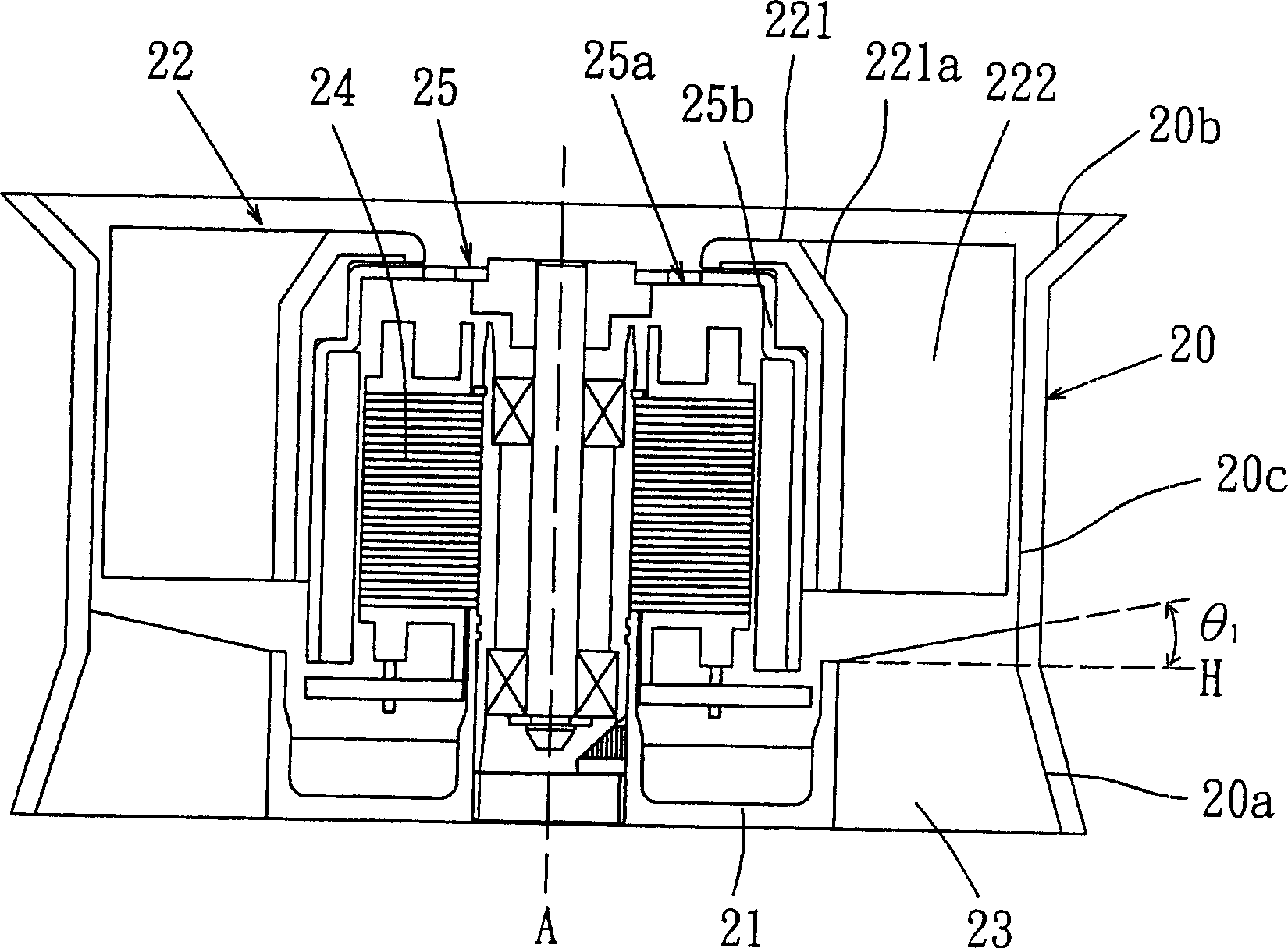

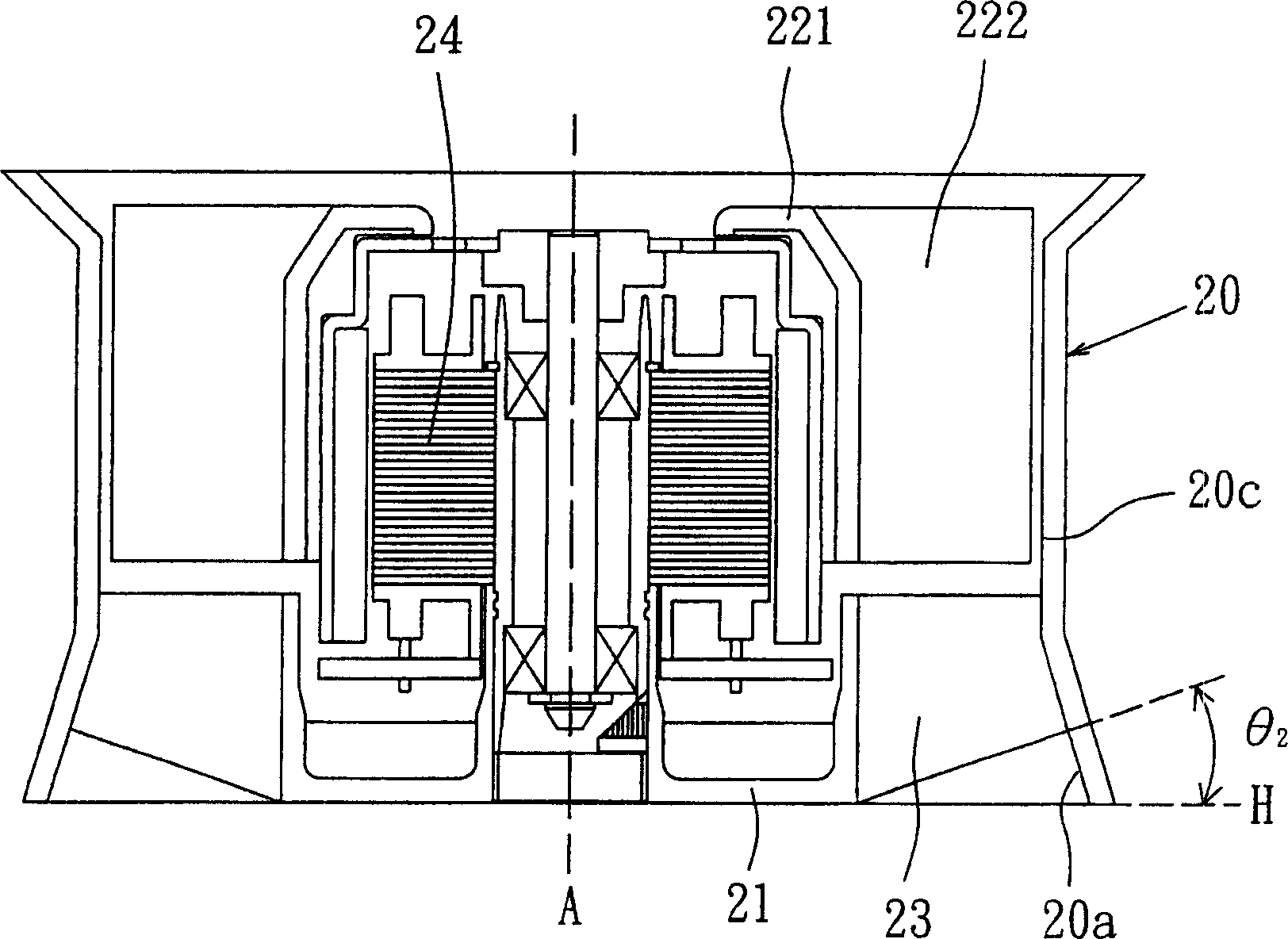

[0053] First, see figure 2 , which shows the first preferred embodiment of the cooling fan of the present invention. The cooling fan includes a frame body 20; a base 21 arranged in the frame body 20; 23 is located at the air outlet side of the cooling fan. Certainly, the air guiding component 23 can also be arranged on the air inlet side of the cooling fan, or be located on the air inlet side and the air outlet side of the cooling fan at the same time. The heat dissipation fan has an impeller 22, which has a hub 221 and a plurality of fan blades 222 arranged around the hub. The top periphery of the hub 221 has a curved structure 221a to guide more air flow to The fan blade 222 . The shape of the frame is in addition to the figure 2 Instead of being shown as a square configuration, it could also be a rectangular or circular configuration. The frame body 20 , the base 21 and the plurality of flow guiding components 23 can be made by integral injection molding, and the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com