Radiating fan

A heat dissipation fan and fan blade technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve problems such as mixed flow, loud noise, poor sound quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

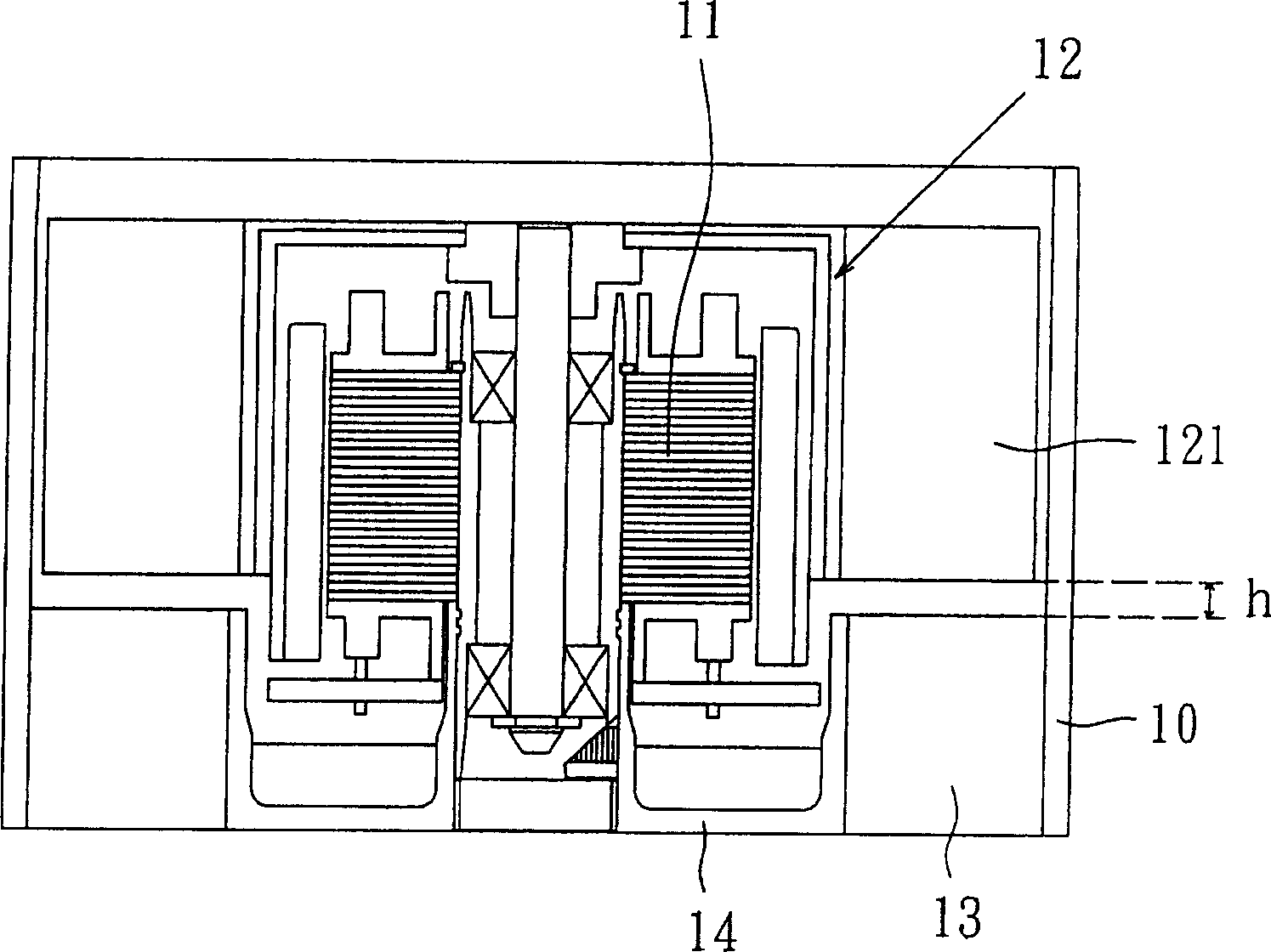

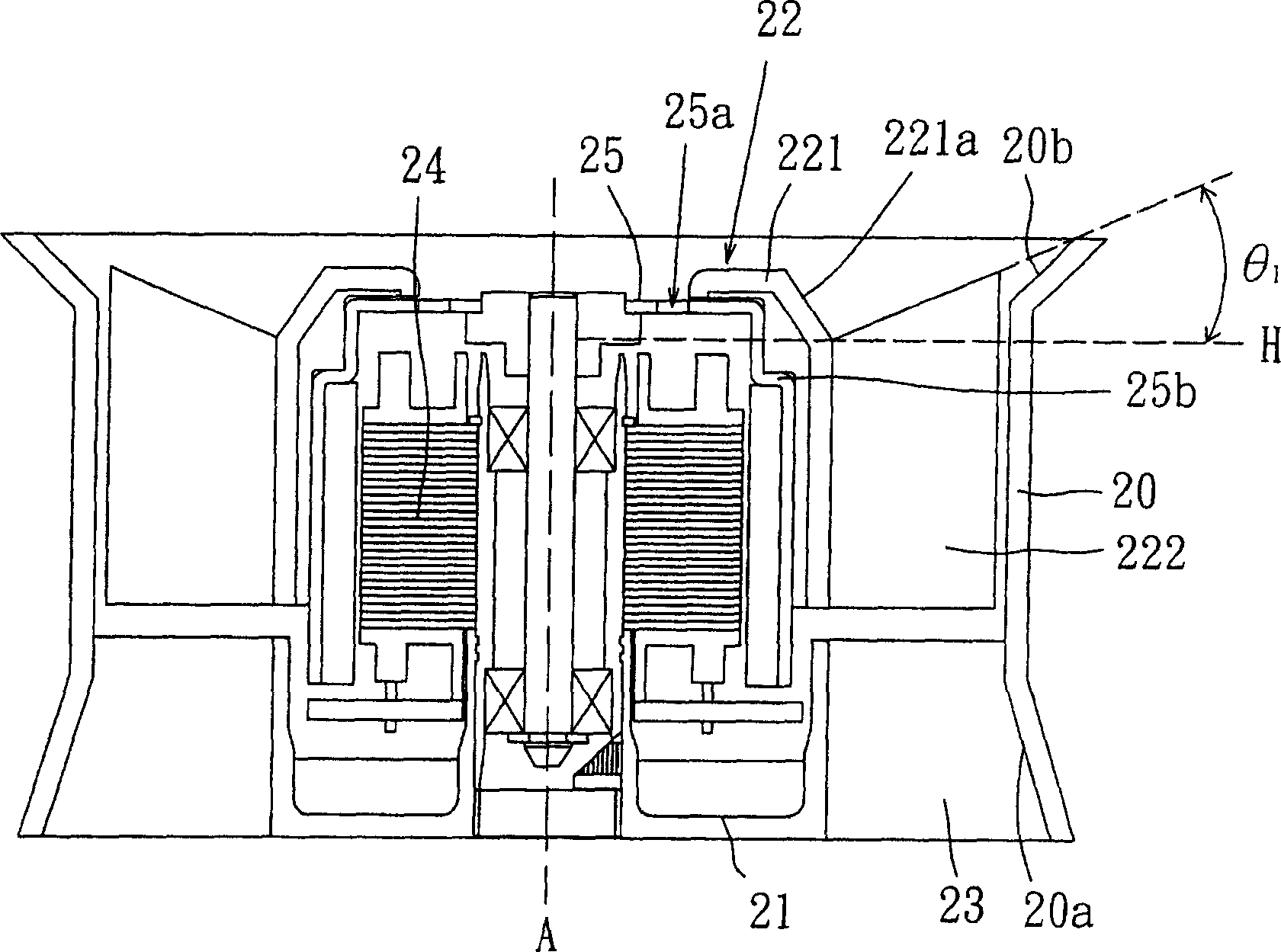

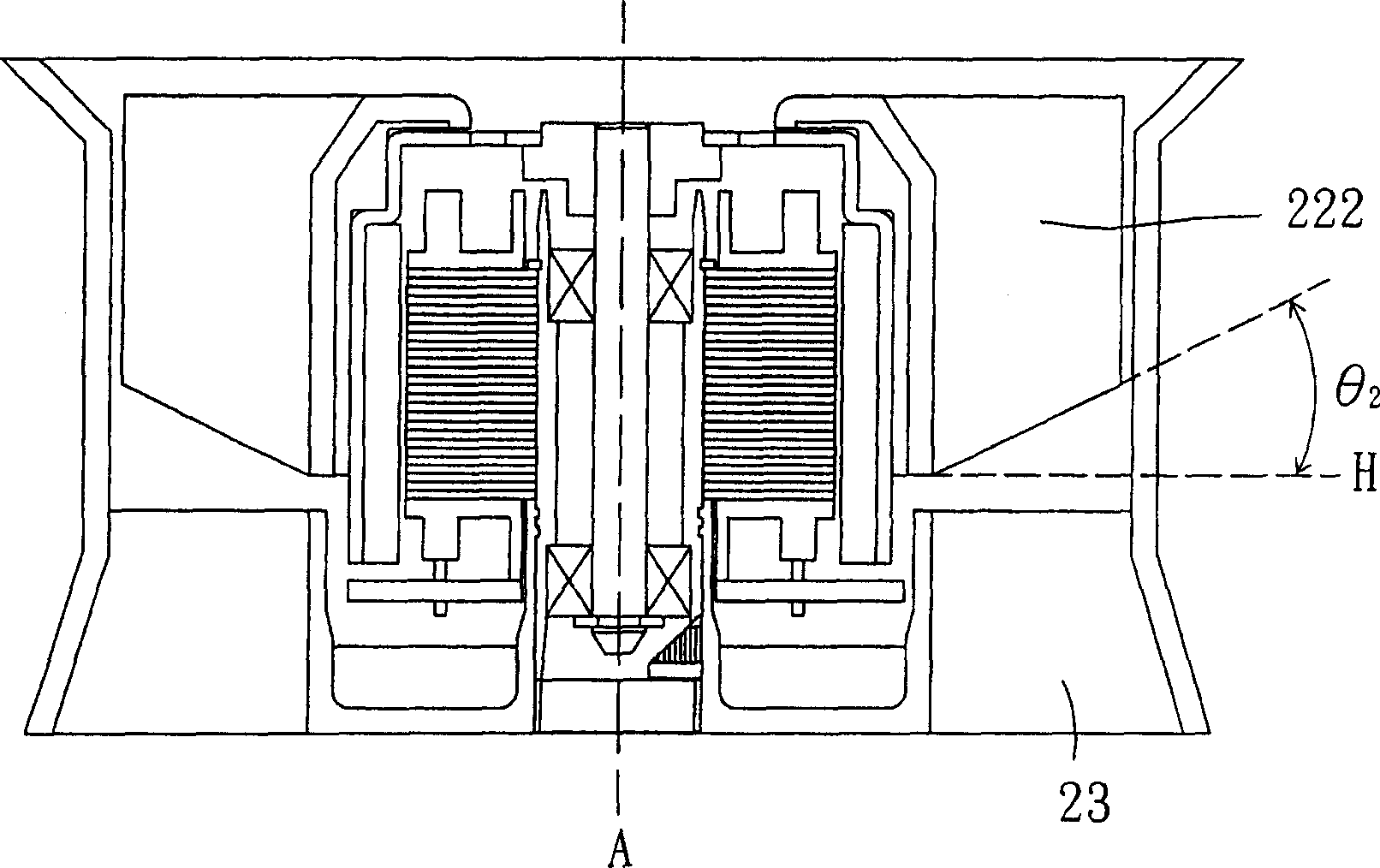

[0045] First, see figure 2 , which shows the first preferred embodiment of the cooling fan of the present invention. The radiating fan includes an outer frame 20; a base 21 arranged in the outer frame 20; Rods or stator blades 23 are located on the air outlet side of the cooling fan. Certainly, the support rod or the stationary vane 23 can also be arranged on the air inlet side of the cooling fan, or be located on the air inlet side and the air outlet side of the cooling fan at the same time. This cooling fan has an impeller 22, has a hub 221 and a plurality of fan blades 222 that are arranged around the hub, and the top peripheral edge of the hub 221 is a slope 221a to guide more air flow to the fan more smoothly. Ye 222. The shape of the frame is in addition to the figure 2 Instead of being shown as a square configuration, it could also be a rectangular or circular configuration. The outer frame 20 , the base 21 and the plurality of support rods or vanes 23 can be mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com