Ion exchanging method for extracting gallium from alumina production process

A technology of ion exchange method and production process, which is applied in the direction of improving process efficiency, etc., can solve the problems of high viscosity of adsorption mother liquor, increase production cost, and low leaching rate, and achieve improved leaching method, reduced production cost, and improved process efficiency. The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

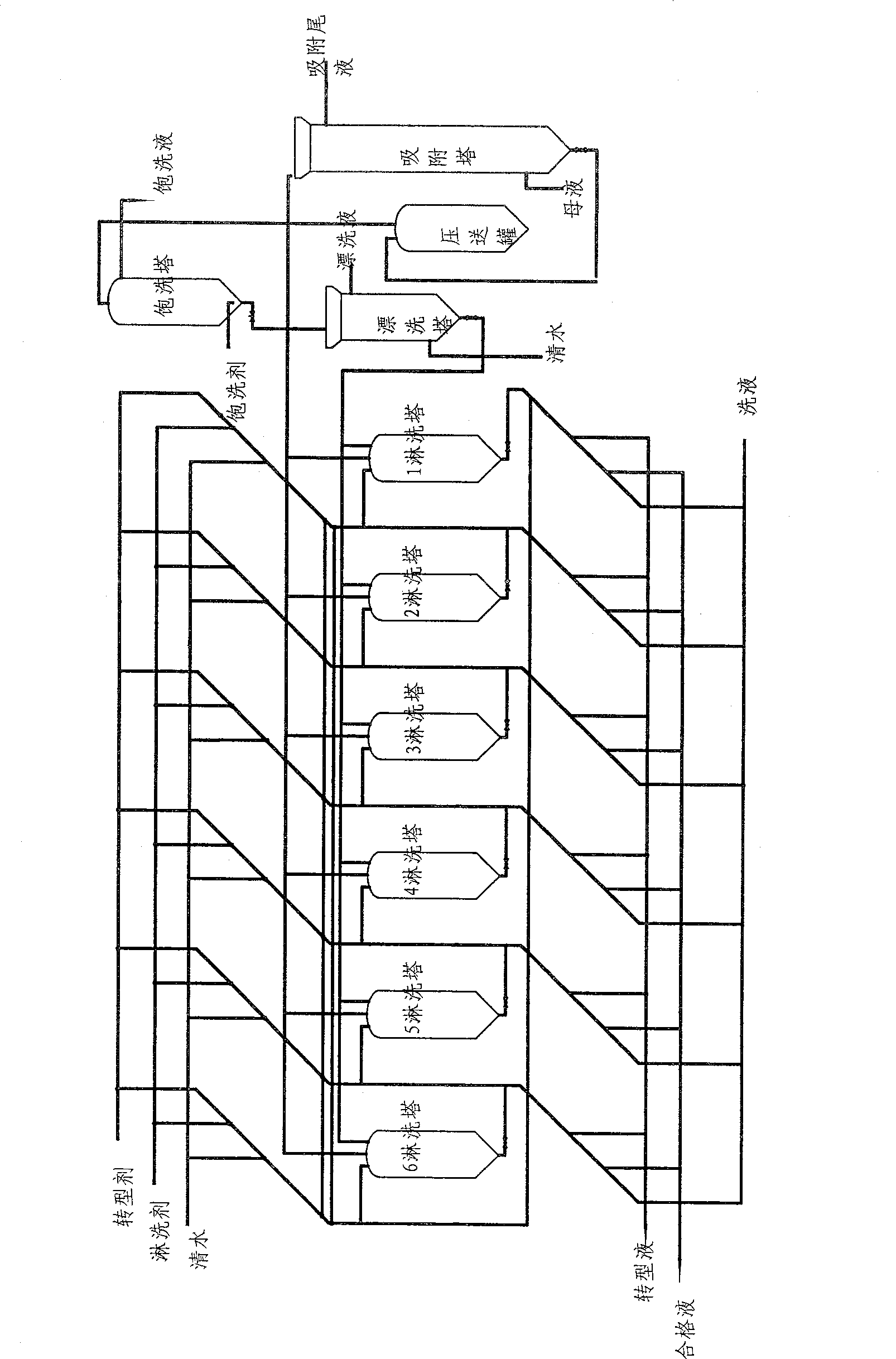

[0022] The method described in this embodiment includes the following steps:

[0023] a. Adsorption process: the resin is sent from the leaching tower to the head of the adsorption tower under pressure, and the resin direction is high in and low out; the mother liquor flows upstream, low in and high out, enters the adsorption tower from the bottom of the adsorption tower, and overflows from the top of the tower out; the adsorption tower adopts dense mobile adsorption, the adsorption time is 1 hour, and the adsorption flow rate is 50m 3 / h, the concentration of the tail liquid reaches 95mg / L; each time the resin is lifted, the resin moves from the tower head to the bottom of the tower once. fully washed;

[0024] b. Full washing In the full washing tower, use clear water to enter the liquid from the lower part and discharge the liquid from the upper part to fully wash the resin in the tower. The empty tower linear velocity is controlled at 10m / h for 1 hour; after full washing,...

example 2

[0030] The difference between this embodiment and embodiment 1 is:

[0031] For rinsing, 4 leaching towers of No. 1-2-3-4 tower are used for rinsing in series, and the eluent is used to enter the liquid from the upper part of the leaching tower and the lower part to discharge the liquid, and the resin in the leaching tower is leached. The line speed is controlled at 9.5m / h, and the time is 1 hour; the No. 4 tower enters the eluent, and the No. 1 tower exits the qualified liquid.

[0032] The transformation adopts No. 5-6 leaching tower, and the resin in the leaching tower is transformed with clean water from the upper part of the leaching tower and the lower part of the liquid.

example 3

[0034] The difference between this embodiment and embodiment 1 is:

[0035] For rinsing, 4 elution towers of tower No. 1-2-3-6 are used for rinsing in series, and the eluent is used to enter the liquid from the upper part of the leaching tower and the lower part to discharge the liquid, and the resin in the leaching tower is leached. The line speed is controlled at 9.5m / h, and the time is 1 hour; the eluent enters the No. 3 tower, and the qualified liquid comes out of the No. 6 tower.

[0036] The transformation adopts No. 5-4 leaching tower, and the resin in the leaching tower is transformed with clean water from the upper part of the leaching tower and the lower part of the liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com